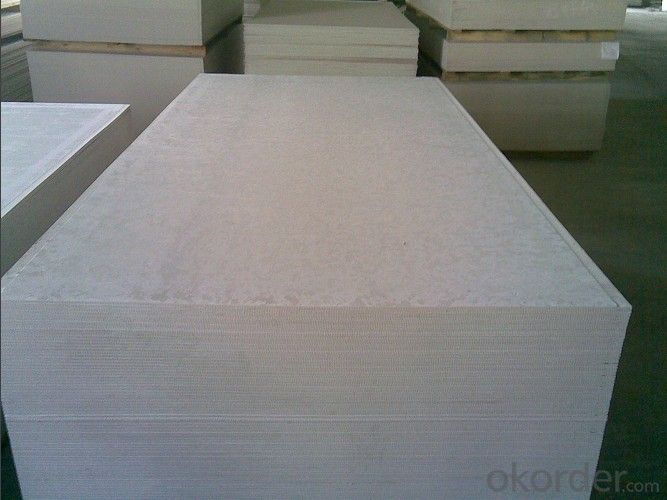

High Density Fiber Cement Board Prices for Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The raw materials of fiber cement board are cellulose fiber, silicate cement, quartz sand, water and some additives. It's a kind of high-tech product which formed through accurate dosing by computer program, hatschek craft and compressed by 14000tons hydraulic machine and autoclaved under high temperature and pressure.

Product Applications:

1. Interior and exterior wall; Furred ceiling

2. Insulation materials, floor; Road barrier

3. Sound-adsorbing wall & suspended ceiling

Product Advantages:

1)excellent fire-proof

2)excellent damp-proof

3)Durability and long service life

4)high strength

5)stable dimensions

6)good heat and sound insulation

7)non-asbestos

8)mould resistant

9)no deformation

Main Product Features:

1) Elegance and excellent decoration

2) Easy installation and convenient maintenance

3) Best Surface processed with PVC Lamination

4) Heat insulation, thermal insulation, moisture proof, mould proof, sound absorption and noise reduction

5) Incombustibility / Fireproof

6) No dust / no pollution

7) Stucturally strong

8) Over 15 years no transmutation

Product Specifications:

FAQ:

1. Q:What is the different and most important point from other supplier?

A:We guarantee No asbestos if it has asbestos density will be more than 1.4g/cm3 what's more

3.2mm*3000*1220mm can be produced by us other suppliers can not do this size

2. Q:What are the advantages of your board?

A: outstanding light weight ,heat insulation, waterproof, fireproof, sound insulation, fast construction.

3. Q: Is the board fire resistant?

A: Yes, fire resistant 4 h , in the heat of 1000℃.actually it is noncombustible Class A1.

4. Q: Do you have any certificate to help us get government's approval?

A:China testing report and our laboratory' s testing by ourselves as your supporting document.

Because building standards are different in different countries, most of our customers buy the boards for testing and get approval by themselves.

5. Q: If we need samples for customer approval, will it be possible?

A: Of course we can.

6. Q:How to guarantee the quality?

A:Laboratory, integral testing process from raw materials to finished product until loading containers will be done by our factory.

Images:

- Q:Its all gonna get covered with mortar anyway when I put the tile on, right? So.... Is it NECESSARY to mortar the joints before hand or not?

- Nothing is necessary of you don't care about water damage. If you care about doing a good quality job that insures that the area is watertight then mud the joints. Remember that water is the worst enemy of a house next to termites. You would be surprised to see what a hairline crack can do to the structure of a house. Not to mention the mold and the insurability of a home. Water damage on an insurance record is shared on a national database of insurers and when its there, good luck every getting insurance.

- Q:Older house, kitchen floor. There's 3/4 diagonal wood on floor joists after hardwood floor is removed. Can I put down 1/2 plywood/ osb and expect the ceramic tile and grout to last? 100% better to use cement board or that synthetic strand board?

- Use the cement board. You may be able to get away with plywood if you were using an adhesive for attaching it, but if you use thinset, the wood will pull the moisture out of it and crack.

- Q:Can you use rubber cement on a science fair poster board to glue papers down?

- Rubber cement will damage some plastics and polished surfaces. If that is not a problem, then it can form a strong yet flexible bond, so may be suitable for your purpose.

- Q:the neighbor has a son and him and his friends constantly makes noise instigating trouble. I complain to the manager, it stops and than starts back up again a week later, so I rather put up something that can help

- Cement board will have little or no effect. Try some type of insulation or acoustical tile. Check with your local building supply. They will tell you what to use.

- Q:What are the differences between the gypsum board and the cement pressure plate and the Eide board?

- Cement pressure plate is based on natural fibers and cement as raw material, by the pulp, forming, cutting, pressing Steamed into a new type of building plate. With light, high strength, waterproof, anti-corrosion, fire, large format, good processing, improve construction efficiency and so on. Mainly used for internal and external walls, pouring walls, composite panel wall panels, fire door lining, external wall insulation panels.

- Q:I'm going to apply cement board over water proof sheet rock,anything special i need to do other than screw it

- There is no such thing as waterproof sheetrock. The greenboard is water resistance at best. Make sure there is the correct waterproofing behind the sheetrock if you don't want problems in the future. Make sure your screw head are sunk flush so they don't hit the back of your tile.

- Q:I know cement board to cement board is taped with thinset and fibatape, but what about the seam at the sides that meet drywall? How should these be taped. What Materials should be used?

- I use a self adhesive fiberglass tape over that seam, and apply 90 minute joint compound over the tape. I assume you are bringing your tile to, or just over that edge anyway. I also assume that that particular joint will be outside the shower curtain or glass, whichever you will be using.

- Q:I need to know if hardibacker board is as good as other cement boards for use behind a tiled shower wall.?

- Yes, its great. I actually prefer that over other cement boards. It seems a lot more durable and easier to work with (cuts similar to drywall). I did a bathroom renovation that I finished a year ago. I used hardibacker on the floor and the walls in the shower as well as half way up the wall in the rest of the bathroom. No leaks, tiles are holding. I'm happy with it and actually plan to use it in every room (even rooms I'm carpeting) to strengthen the floor and minimize noise on the lower levels.

- Q:Use the cement board to do the bathroom partition, how to do waterproof, with which waterproof material is better

- Bathroom directly with cement to do waterproof is not enough.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Density Fiber Cement Board Prices for Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

Offcanvas right

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords