Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Cement Boards) Description

From 6mm Fiber Cement Board to 24mm presents the art of Germany know-how as a high quality building material.

6mm Fiber Cement Board to 24mm and sandwich panel contains inorganic raw materials such as cement, silica powder and reinforced cellulose fiber as the main materials. All SIGMA boards are autoclaved to become stable product. Fiber Cement Board does not contain any of asbestos fiber, however, it has strong bending strength like those with asbestos.Fiber Cement Board can be applied not only for the interior use but also for the outdoor wall system. It has low water absorption rate and high impact resistant ability. These good advantages make it suitable for any purposes of applications.

2,Main Features of the (Cement Boards)

Properties:

·100% Non-asbestos

·Density: 1250 to 1500 kg/m3 (+ - 5%)

·Coefficient of thermal expansion: 0.11 kcal/m.hroC

·Bending Strength: over 180 kgf/cm2

·Linear expansion rate: 0.1%

·Water absorption rate: 35%

·Water penetration rate: 0%

·Water content: 8%

·Incombustibility according to CNS 6532 and BS 476

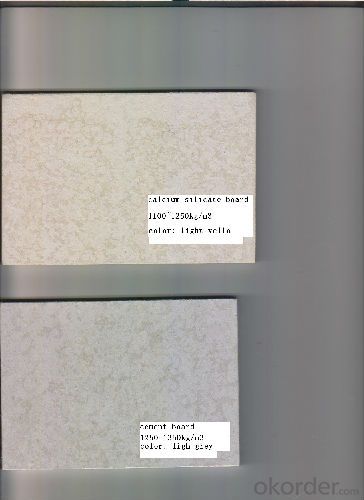

3,(Cement Boards) Images

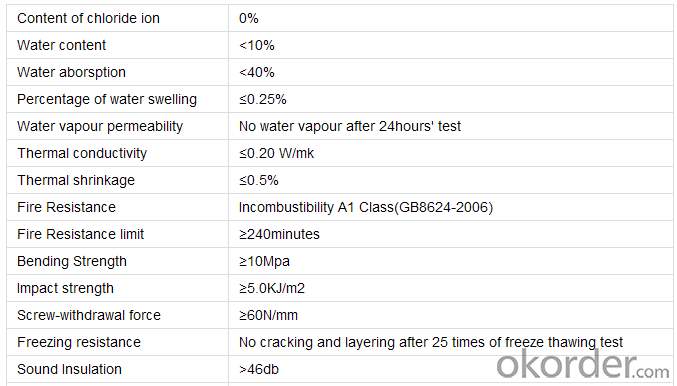

4,(Cement Boards) Specification

5,FAQ of (Cement Boards)

1.Hold by Wooden Pallet

2.Covered by PVC and Bonded with plastic belt

3.Fasten around the corners

4.Mounted in container to protect your purchasing

- Q: What do I do

- it may be broke

- Q: I have asbestos shingles and i need to vent a portable a/c so i'm going to replace a few shingles with fiber cement board so i can cut them. i heard these things are a nightmare to cut.

- Go to any rental place they rent these drills and bits that have diamond tips for cutting concrete. And use water to hold down the dust. Should have any size you need.

- Q: Yesterday I started a job at a warehouse store. This store, being a warehouse has cement floors. I have a pair of walking shoes I wear with added inserts for more comfort, but after my shift yesterday, I could barely walk because of the pain in my hips, knees, foot/leg joint, and my ankles. I know that arthritis runs in my family, and that other family members have had problems when dealing with cement floors. I'm only 23, but I know arthritis can start that young (I also know my knees are total crap because of sports). So my question is, could this pain be from walking on the cement floors all day, or is this just random? I never had this happen this bad before, and have never had to be on cement floors that long either.

- Hi there: I know this the floors will just kill my feet when working on cement. You have a fine day..

- Q: do i need to put cementious backer board behind a fiberglass surround shower unit?

- no,,not if its a full surround,,,use green board sheet rock around the edges though

- Q: Light steel keel cement board is what

- Light steel keel cement board refers to the light steel keel-based skeleton of the cement board.

- Q: What is the average price for hardieplank(cement board) installation?

- Anywhere from $10 to $15 per square foot depending upon how cut up it is. Large walls with not many cuts - $10. Small expanses with lots of angles and cutting - $15 of more if really complex. This includes the hardie product, the water proofing and the fasteners.

- Q: Cement board in Malaysia?

- you can find cement board sell in most hardware shop in malaysia

- Q: Gypsm plaster is recommended in Christopher Alexander's Pattern Language (#235 Soft Inside Walls) If I were to go to a building supply store and ask for gypsum plaster would they know what I was talking about? ...Is it a universal term? Can you give me a chemical formula?

- Gypsm is hydradated pulverized limestone. You would ask for Gypsym topcoat or Gypsm tape adhesive in the Drywall department of Lowes. It costs today $9.95 for a 5 gallon pail of the stuff. Gypsm is resoluable in water after drying. In other words you can redissolve gypsm in water. Gypsm is mined in the US in states like Michigan, Indiana, Ohio and so on. It is a naturally occuring substance. Plaster of Paris is unhydrated form of lime. When wetted with water it changes chemically and remains hard no matter if submerged into water. The process is irreversible. Cement is made from clay and limestone fired to high temperatures, then ground and pulverized. When water is added to cement it changes its chemistry and the water reacts with cement forming a new compound It is irreversible The Romans invented Cement. Common Drywall is gypsm between 2 layers of paper enclosure. There are also metal lath in 26x84 inch lenghts and plaster board lath in 16x36 inch lengths Those all above are nailed or glued to the house studs.

- Q: How much is the cement board?

- Cement board raw materials generally do not sell according to the square Zhang, each 1220MM * 2440MM gypsum board than some of your 20-25 look.

- Q: I want to install ceramic tile in my kitchen. My subfloor consists of 2x8 on 16 centers with 1/2 5 ply plywood. Will it be OK to lay 1/2 cement board directly on this or do I need to some how increase the strength of the subfloor? Any recommendations.

- you could do that and MAYBE not have a problem. but if it was me, the 1/2 would come out and 3/4 would replace it. i have done a few jobs for people that dont want to replace the 1/2 and didn't have any problems with the tile or grout lines cracking. its just up to you really. if there is ANY give at all on you floor right now, id replace the 1/2.

Send your message to us

Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords