Staining Particle Board

Staining Particle Board Related Searches

White Laminated Particle Board Perforated Particle Board Recycle Particle Board Stainless Steel Draining Board Waterproof Particle Board 1 Inch Particle Board Screwing Into Particle Board Stainless Steel Peg Board Hemp Particle Board Maple Particle Board Formaldehyde Particle Board Acoustic Plaster Board Stainless Steel Running Boards Particle Board Pallets Raw Particle Board Pe Coated Board Refinishing Particle Board Cabinets Stainless Steel Baseboard Tubular Particle Board Stainless Steel Pickling Paste Extruded Polystyrene Foam Board Particle Board Nz 4 X 8 Particle Board Bagasse Particle Board Particle Board Specifications Plywood MDF Particle Board Particle Board Adalah Stainless Steel Drainboard Render Board Stainless Checkered PlateStaining Particle Board Supplier & Manufacturer from China

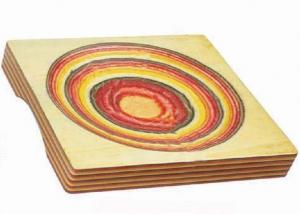

Staining Particle Board is a versatile and popular material used in various applications due to its affordability and ease of customization. This type of particle board is specifically designed to accept stains and finishes, making it an ideal choice for furniture making, cabinetry, and other woodworking projects where a more natural or distinctive look is desired. The staining process allows the wood grain to show through, giving the particle board a more authentic wood appearance that can be further enhanced with various stains and finishes.Staining Particle Board is widely used in both residential and commercial settings, where its durability and cost-effectiveness make it a preferred choice for many designers and builders. Whether it's for creating custom furniture, updating kitchen cabinets, or constructing built-in storage solutions, this product offers a practical and visually appealing option. Its ability to be stained and finished in various ways also allows for greater flexibility in design, enabling users to achieve a wide range of aesthetic outcomes that suit their specific needs and preferences.

Okorder.com is a leading wholesale supplier of Staining Particle Board, offering a vast inventory of this product to cater to the needs of businesses and individuals alike. With a commitment to quality and customer satisfaction, Okorder.com ensures that their Staining Particle Board meets the highest standards, providing a reliable and consistent product for all types of woodworking and construction projects. Their extensive inventory and competitive pricing make them an ideal choice for those looking to purchase Staining Particle Board in bulk or for specific projects.

Hot Products