Perforated Particle Board

Perforated Particle Board Related Searches

Formaldehyde Particle Board Recycle Particle Board Staining Particle Board Particle Board Specifications Waterproof Particle Board Tubular Particle Board Particle Board Pallets White Laminated Particle Board 1 Inch Particle Board Perforated Aluminum Plate Raw Particle Board Hemp Particle Board Perforated Pvc Pipe 4 X 8 Particle Board Particle Board Nz Compressed Foam Board Screwing Into Particle Board Bagasse Particle Board Maple Particle Board Extruded Polystyrene Foam Board Plywood MDF Particle Board Particle Board Manufacturers Association Particle Board Adalah Pe Coated Board Osb Particle Board Particle Board Manufacturers Usa Tapered Insulation Board Fibre Board Acoustic Plaster Board Particle Board MalaysiaPerforated Particle Board Supplier & Manufacturer from China

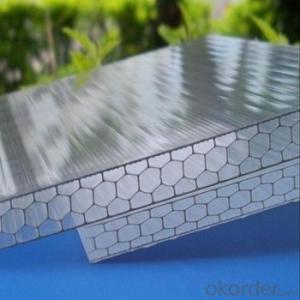

Perforated Particle Board is a versatile construction material that combines the strength of particleboard with the added functionality of perforations. These perforations allow for easy installation of various fixtures and fittings, making it an ideal choice for a wide range of applications. The product is designed to offer durability and stability, while also providing a cost-effective solution for various construction and interior design projects.This type of particle board is commonly used in furniture manufacturing, office partitions, and wall paneling, where the need for a strong yet lightweight material is essential. The perforations in the board also facilitate better airflow and sound insulation, making it suitable for applications where these factors are crucial. The versatility of Perforated Particle Board allows it to be used in both residential and commercial settings, providing a practical and aesthetically pleasing option for various design needs.

Okorder.com is a leading wholesale supplier of Perforated Particle Board, offering a vast inventory of this product to cater to the demands of various industries. As a reliable source for this material, Okorder.com ensures that customers receive high-quality products at competitive prices. With a commitment to customer satisfaction, Okorder.com stands out as a trusted provider of Perforated Particle Board, helping businesses and individuals achieve their construction and design goals.

Hot Products