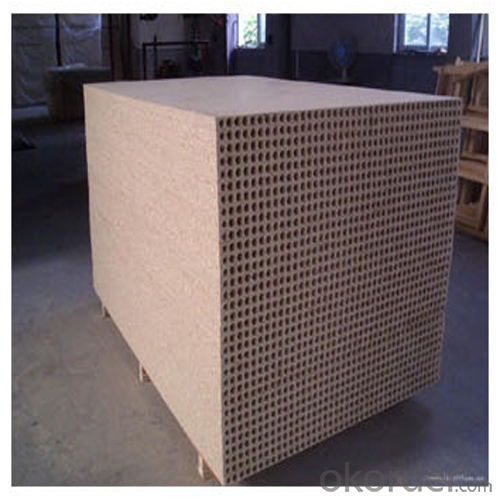

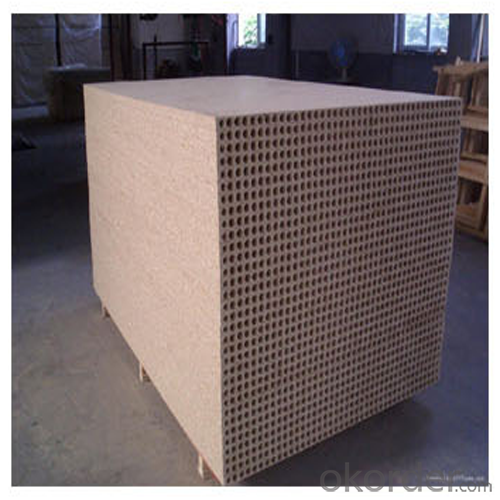

Hollow/ Tubular Particle Board for Environmental Protection

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details:

· Type: Fibreboards

· Place of Origin: Shandong, China (Mainland)

· Model Number: 900*2000mm, 1250*2000mm

· Material: Wood Fiber

· Usage: Indoor

· Grade: First-Class

· Fibreboard Type: Low Density Fibreboards / Softboards

· Formaldehyde Emission Standards: E1

Packaging & Delivery:

Packaging Details: | standard seaworthy packing |

Delivery Detail: | within 15 days after receiving the deposit |

INTRODUCTION:

1. product name: hollow particle board, tubular particle board/chipboard

2. used for the core of flat door and isolation board

3. size: 900*2000mm, 1250*2000mm, or as customer required

4. thickness: 28, 30, 33, 34, 38,

5. width: 900mm, 1250mm or as requsted

6. hole diameter: 21-28mm

7. materials: poplar , mix hardwood

8. loading quantity: 33*1250*2000 for example, 630pieces/40HQ

ADVANTAGEMENT AND USAGE:

Environmental protection, heat preservation, sound insulation, light in weight , anti-impact, stable in dimensions and easy to processing

It can be used for door core, furniture, decoration, wall stuffing, etc.

TECHNICAL DATA:

1. density: 340/350kg/m3

2. density tolerance: +/-15%

3. moisture content: 5-13%

4. water absorption rate: <5%

5. static bending strength: >0.9Mpa

6. internal bond strength: >0.7Mpa

7. formaldehyde released: E1 or E2

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, if needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

We are mainly producing plywood, film faced plywood, particle board, blockboard, MDF, HDF, OSB and other kinds of wood productions.

If you have any interest in above productions, pls feel free to contact with us.

We are servicing our clients abroad with competitive price and faithful attitude.

Wish to have a mutual bright future with you!

Product Show:

- Q: What is the difference between a steel plate sandwich board?

- Pressure plate also known as wave plate, the general is the use of color coated steel plate, the cold bending into a variety of wave-type pressure plate. Sandwich panels, also known as composite panels, the color coated steel or other panels and the bottom plate and insulation core material through the adhesive (or foam) compound ?????????????????? Into the insulation composite sheet. The simplest difference is that the pressure plate is a veneer sandwich panel is a composite board

- Q: There is a comprehensive building, a two-story canteen, three-story activity room, the roof for the Caigang sandwich panel roof, the building fire rating for the two, the roof sandwich board design using polystyrene foam sandwich panels can?

- Can not. Polystyrene foam sandwich panels are mostly flammable and flammable, preferably flame retardant, and the burning properties of their materials do not meet the requirements of Grade II refractory grade buildings. Our province has been a few cases of Caigang sandwich panel roof fire cases, due to sandwich material led to the rapid expansion of fire.

- Q: V950 color steel rock wool sandwich panel and v960 color steel rock wool sandwich board what does it mean

- Is the practical width of the tile of 950 watts a meter long is 0.95 level 960 is 0.96 level

- Q: What is the meaning of the bulk density of double-sided color steel polyurethane panels?

- Double-sided color steel rigid polyurethane plate its bulk density of 35 ~ 40kg / m3, thermal conductivity: 0.018-0.023, low thermal conductivity, thermal performance.

- Q: EPS corrugated composite board and corrugated sandwich board What is the difference, 50MMEPS corrugated composite board (0.5 on the next 0.4) to do the plant roof construction process is how The price is almost a square?

- EPS corrugated composite board is a corrugated sandwich board, according to the core of the different corrugated sandwich panels are divided into EPS corrugated sandwich panels (that is, EPS), extruded sandwich panels, polyurethane sandwich panels and rock wool sandwich Plate and so on. Construction is the steel structure plus sandwich panels.

- Q: Color steel sandwich panel of the relevant parameters

- Product performance: thickness 0.2mm ~ 1.0mm Core thickness: 50mm ~ 250mm Effective height: 1000mm, 1200mm, 960mm.950mm Scope: workshop, office walls, steel structure of the external walls Maintenance, decorative building materials, activities, such as office buildings Fire rating: B1 ~ B3 (flame retardant: melting) Moisture absorption: 3.9 (%)

- Q: How to choose the type of steel structure plant roof sandwich panels

- Steel plant roof, should be based on the use of plant sandwich panels: 1, the general plant roof with ordinary double-pressure steel plate polyethylene foam sandwich panels, sandwich material thicker, insulation, the better the insulation effect. 2, into the deep larger house, and the need for natural light of the plant, the roof sandwich panels should use transparent, translucent sandwich panels. For example: transparent plastic sandwich panels. 3, the fire requirements of the plant, the roof with fire double-sided steel plate Yanmian sandwich panels, can also have, insulation, insulation, fire performance. This sandwich panel must meet the design requirements of the fire rating. And, the factory floor of the steel structure, should brush fire paint; doors and windows with fire doors and windows.

- Q: Color steel sandwich panels and C steel belongs to what industry

- Should be considered building materials it Make the house with the thing.

- Q: Are thermocol roof insulation boards or thermocole sandwich concrete bricks durable?

- I typed in thermocol and this is what it gave me. Hope it helps. polystyrene (p?l'ēstī`rēn), widely used plastic plastic, any organic material with the ability to flow into a desired shape when heat and pressure are applied to it and to retain the shape when they are withdrawn. Polystyrene is a colorless, transparent thermoplastic that softens slightly above 100°C; (212°F;) and becomes a viscous liquid at around 185°C; (365°F;). It is resistant to acids, alkalies, oils, and alcohols. It is produced either as a solid or as a foamed plastic marketed under the trade name Styrofoam. Its many uses include electrical and thermal insulation, translucent window panels, storage-battery cases, and toilet articles

- Q: What does this product represent?

- Representative of the color steel sandwich panel model

Send your message to us

Hollow/ Tubular Particle Board for Environmental Protection

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords