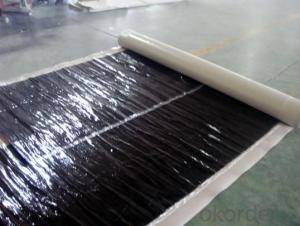

Protecto Board Bituminous Membranes

Protecto Board Bituminous Membranes Related Searches

Bitumen Protection Board Bituminous Geomembrane Liner Bitumen Roofing Membrane Bitumen Geomembrane Particle Board Pallets Waterproofing Membrane Philippines Tubular Particle Board Prefabricated Geomembranes Pre-Seamed Geomembranes Protective Paints Compressed Foam Board Paintable Waterproof Membrane Bentonite Waterproofing Membrane Impermeable Geomembranes Structural Insulated Panels Waterproof Particle Board White Laminated Particle Board Particle Board Specifications Geocomposite Membrane Particle Board Malaysia Rigid Polyurethane Foam Board Permeable Geomembrane Bolsas De Geomembrana Plastic Wall Corner Protectors Recycle Particle Board Geomembranes Damp Proof Membrane Conductive Geomembrane Protective Netting Geomembrane ProductsProtecto Board Bituminous Membranes Supplier & Manufacturer from China

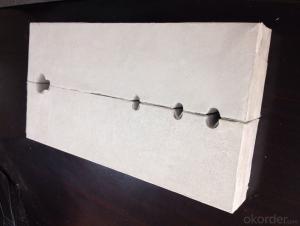

Protecto Board Bituminous Membranes are a type of waterproofing material designed for various construction applications. These membranes are made from bituminous compounds and are known for their durability and effectiveness in preventing water infiltration. They are commonly used in roofing, foundation, and wall applications, providing a reliable barrier against moisture and other environmental factors that can cause damage to structures. The versatility of Protecto Board Bituminous Membranes makes them a popular choice among contractors and builders for a wide range of projects.In terms of application and usage, Protecto Board Bituminous Membranes are ideal for both new construction and renovation projects. They can be easily installed over various surfaces, including concrete, wood, and metal, providing a seamless and watertight seal. The membranes are also compatible with a range of other waterproofing products, allowing for customized solutions tailored to specific project needs. Whether it's a residential home, commercial building, or industrial facility, Protecto Board Bituminous Membranes offer a dependable and long-lasting solution for protecting structures from water damage.

Okorder.com is a leading wholesale supplier of Protecto Board Bituminous Membranes, offering a vast inventory to meet the demands of various construction projects. With a commitment to quality and customer satisfaction, Okorder.com ensures that their products are of the highest standard and readily available for purchase. This makes them a reliable source for contractors, builders, and other professionals in the construction industry who require these membranes for their projects. By partnering with Okorder.com, customers can benefit from competitive pricing, fast shipping, and excellent customer service, ensuring a smooth and efficient purchasing experience.

Hot Products