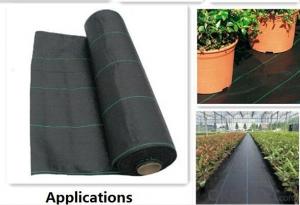

Geotextile Fabric

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

made of polyester or polypropylene fiber

good burying, hydrolyzation & corrosion resistibility

Density | Thickness | Breaking Strength | Elongation of Fracture | CBR Bursting Strength | Vertical Penetration Parameter | Equivalent Aperture |

g/m2 | mm | KN/m | % | KN | cm/s | O95 mm |

65 | 1.2 | 2.8 | 40 ~ 80 | 0.7 | K x (10-1 ~ 10-3)

(K = 1.0 ~ 9.9) | 0.07 ~ 0.2 |

75 | 1.4 | 3.3 | 0.8 | |||

100 | 1.6 | 5.0 | 0.95 | |||

150 | 1.52 | 7.5 | 1.5 | |||

160 | 2.0 | 8.5 | 1.60 | |||

200 | 2.4 | 11 | 2.10 | |||

250 | 2.8 | 14 | 2.60 | |||

300 | 3.4 | 16 | 3.20 | |||

400 | 4.0 | 21 | 4.0 | |||

500 | 4.5 | 25 | 4.8 |

- Q: Can the cushion on the prefabricated board floor be dug?

- Surface layer without steel, do not bear the load, you can dig out But sometimes the prefabricated floor above the surface layer with steel, to bear the load, this can not be removed! To know how thick the cushion, in the local dig about In general, to do leveling layer, can not be directly laid tiles

- Q: When the cushion is used, the thickness of the protective layer is not less than ()

- The purpose of the protection, one is to avoid man-made mechanical damage; the second is to prevent climate, UV aging, to extend the service life; three in the planting roof protection layer is to prevent plant roots puncture, different effects using different methods of protection.

- Q: Why do the basics of the cushion waterproofing

- As for the bottom of the bar thickness of the protective layer is generally 4cm, but if the basic floor of the concrete label is relatively high, the protective layer can be appropriately reduced.

- Q: The top floor made waterproof playing cushion layer of how to do

- Roof waterproofing can not use a single waterproof material, must be rigid and flexible combination of construction, flexible waterproof stretch is good, a little bit of settlement or deformation will not damage the waterproof layer. Rigid waterproof (ie mortar waterproofing agent) waterproof at the same time, can play a protective role, waterproof layer is not easy to be destroyed.

- Q: Basement cushion waterproof

- Fourth, improve the waterproof performance: 1, Aggregate graded concrete, is the use of different aggregates of the aggregate and improve the content of cement mortar in the concrete, so that the mortar is filled between the aggregate, thus blocking the aggregate is not dense between the seepage channel , Improve water resistance; 2, plus concrete, is added in the concrete air conditioner or dense agent to improve the impermeability.

- Q: Can the floor tiles be removed from the cement mats on the prefabricated board floor?

- Prefabricated board floor layer of cement layer is not called the cushion, should be called leveling layer, this layer can be eradicated, but should pay attention not to damage.

- Q: What is the relationship between the cushion and the ring beam?

- There is no direct relationship between the cushion and the ring beam.

- Q: Is foam concrete suitable for use as a cushion?

- The foamed concrete is a foaming system through a foaming machine that allows the foaming agent to be fully mechanically foamed and the foam is mixed evenly with the slurry.

- Q: How to build a fine stone concrete cushion?

- Reduce ground cracking, plus steel mesh. Reinforced mesh, should be placed in the middle of the concrete, because the protective layer of concrete thick Fang generally only 5CM thickness, so the middle is the best.

- Q: Basement floor mattress dry to what degree can do coil waterproof?

- Pull a square coil, tiled on the floor above, in the case of the sun, the sun shines on half an hour, in turn, look at the coil, if no water to prove that the water content is not large, that can be construction.

Send your message to us

Geotextile Fabric

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords