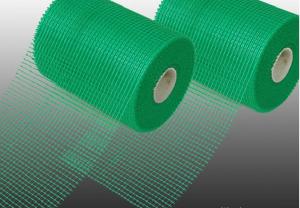

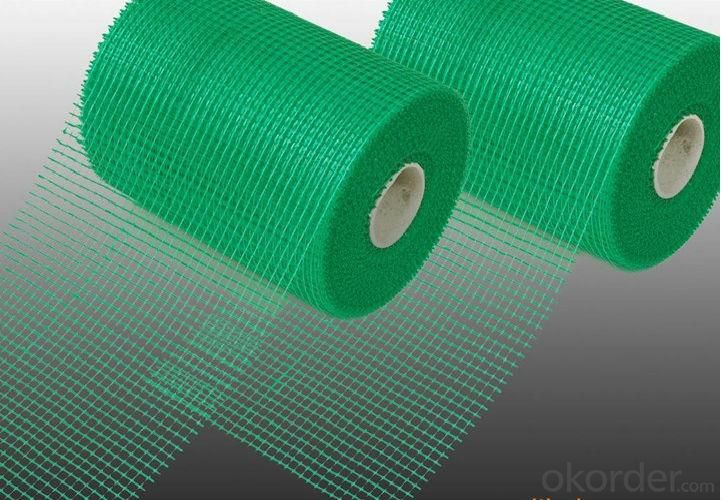

PE GRID FABRIC

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 20 Container Per Month m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

PE GRID FABRIC

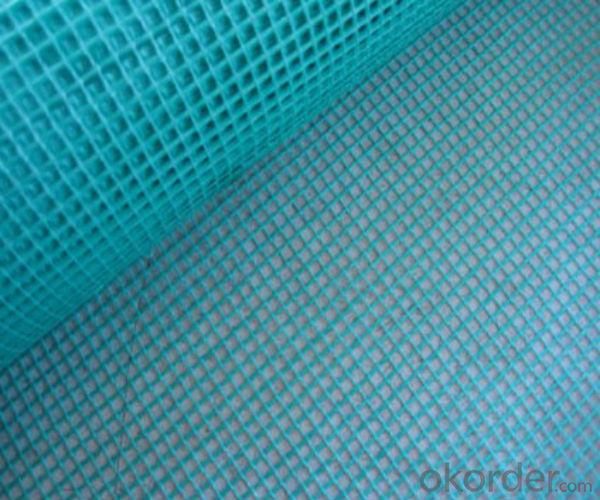

Material : 100% virgin PE, Polyethylene, Leno type woven PE fabric, 3x3/sq.inch

Specification of PE grid fabric:

* Denier:2000/ 2400 Denier

* Density/sq. inch: 3x3/sq.inch, both sides laminated

* Weight: 100gsm-200gsm

* Color: white, green. transparent film

Type of PE grid fabric:

* Finished size with ropes in hem and eyelets every 3 feet. Customized sizes.

* Roll size to pe packed 2m*100m/roll, 2m*50m/roll, 2m*25m/roll.

Application of PE grid fabric:

*GENERAL COVER

*SCAFFOLDING : For the construction buildings, prevrention from dropping

dangerous things, keeping warm, it prevents dust and contaminated dirt from

the inside of the construction buildings.

*ROOFING : Waterproof from outside and keep away from wetness inside of the roof.

dangerous things, keeping warm, it prevents dust and contaminated dirt from

the inside of the construction buildings.

*ROOFING : Waterproof from outside and keep away from wetness inside of the roof.

- Q: Do you need a cushion on the ground floor?

- As well as the time to build a wooden building with concrete pier, from the ground or contact the ground to do a good job preserving.

- Q: Can the cushion on the prefabricated board floor be dug?

- Prefabricated board floor layer of cement layer is not called the cushion, should be called leveling layer, this layer can be removed, but be careful not to damage the prefabricated plate.

- Q: Roof waterproof mattress should play the number of centimeters appropriate

- ? 3. The first layer to do flexible waterproof, that is, roof-specific anti-aging waterproof coating.

- Q: Do you need a cushion for roof waterproofing?

- There is no "cushion" on the roof, and there is a concrete cushion under the basement floor. What you said may be leveling, is the base of the waterproof layer.

- Q: When the cushion is used, the thickness of the protective layer is not less than ()

- Not on the roof: the general waterproof layer above can be used 15 ~ 25mm cement mortar protection.

- Q: Basement cushion waterproof

- Five, how the basement moisture: 1, moisture-proof material This is the decoration in the attention of the problem, the basement is relatively humid place, so when we should pay attention to the decoration, the choice of wallpaper, tiles and other moisture-proof effect of better decoration materials, and other basement ceiling, floor, walls are To be the best waterproof. 2, ventilation and moisture Strengthen the air circulation on the moisture is more helpful, can effectively reduce the indoor moisture content. 3, electrical dehumidification If you run into the rainy weather, outdoor air humidity is relatively high, it is not suitable for long ventilation, you can use the exhaust fan, air conditioning or dehumidifier and other machines for indoor dehumidification. 4, desiccant dehumidification In addition to the use of a variety of electrical dehumidification can also be placed some moisture damp dehumidification effect of small items, such as desiccant, charcoal and other indoor moisture, but the desiccant is a service life, the general need for frequent replacement. 5, to warm moisture Installation of warmth is also one of the effective means of underground moisture protection, to warm the basement room temperature can be maintained at a certain temperature can keep the room dry and not wet, but pay attention to the temperature is not too high will cause the room is too dry, Comfortable.

- Q: Cushion, waterproof layer construction to do what information

- 2, bedding (bed course) refers to the structure below the grass-roots level. Its main role is to water, drainage, antifreeze to improve the grass-roots and soil-based working conditions, the water stability requirements are better. The cushion layer is a structural layer between the base layer and the soil base. When the soil quality is poor, it is used to improve the water stability of the soil base, improve the water stability and frost resistance of the pavement structure and disperse Load to reduce soil deformation.

- Q: Is foam concrete suitable for use as a cushion?

- And then through the foaming machine pumping system for cast-in-place construction or mold forming, the formation of natural conservation with a large number of closed pores of the new lightweight insulation materials.

- Q: Why calculate the amount of time to count a lot of cushion ah

- ? In the municipal engineering, the bedding layer is a structural layer between the grassroots and the soil foundation. When the soil temperature is bad, the water temperature of the soil is improved and the water stability and frost resistance of the pavement structure are improved. Diffusible load to reduce soil deformation.

- Q: Maintenance time of the cushion on the roof of the building

- Concrete watering maintenance time: the use of Portland cement, ordinary Portland cement or slag Portland cement mixed with concrete, not less than 7d;

Send your message to us

PE GRID FABRIC

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 20 Container Per Month m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords