PMB-741 Elastomer (SBS) Modified Bituminous Waterproof Sheet Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Elastomer (SBS) Modified Bituminous Waterproof Sheet Material is a thermoplastic and elastic

modified bituminous dipping and coatingmaterial made out of Stylene-Butadiene-Stylene (SBS),the filler base is polyester felt, glass fiber felt and glass fiber reinforced polyester felt, it is a kind of rollable sheet water proof materials with the surface cover of the isolating materials like polyethylene film, fine sand and mineral slice (or particle) etc.

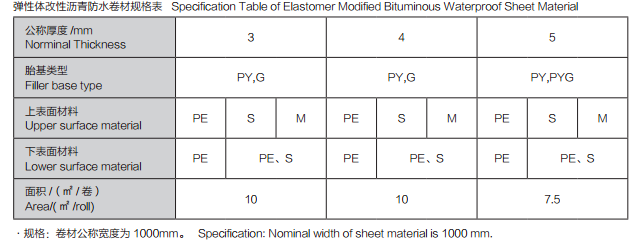

Type and Specification

Classified by filler base: Polyester filler (PY), glass fiber

filler(G) and glass fiber reinforced polyester filler (PYG).

·Classified by upper surface isolating material: Polyethylene

film (PE), fine sand (S) and mineral particle (M).

·Classified by lower surface isolating material: Fine sand

(S) (note: the mineral particle with the fine sand diameter not

more than 0.6mm) and polyethylene film (PE).

·The physical and mechanical properties were divided in

Type Ⅰ and Type Ⅱ.

Advantages

—Filament polyester filler base sheet material:

·The combination of filament polyester filler base and SBS

modified bitumen, forms a high performance and high class

comprehensive water proof sheet material.

·Forming a high strength water proof layer, to have strong

resistance agaist water pressure.

·Good performance of breaking resistance, tearing resistance,

fatigue resistance, corrosion resistance, mould resistance and

weather resistance;

·High tensile strength, high elongation, high adaptive capacity to

base shrinkage,deformation and fracture.

·Good resistance performance of low and high temperature: It

still works under -50 ℃ , adaptive to cold and hot surroundings,

especially in chilly region.

·Good workability: Hot melt cementation, we are able to contruct

in the four seasons of the whole year, hot-joint is able to be reliable

and durable.

—Alkali-free glass fiber filler base sheet material:

·Combination of economical filler base and high performance

SBS modified bitumen.

·Higher tensile strength, excellent resistance to high and low

temperature.

·Good performance of corrosion resistance, mould resistance,

weather resistance and good workability.

—Glass fiber reinforced polyester filler base sheet material:

·We may use mechanical mounting method to construct, and it is

safe and environmentally friendly.

·The product has better dimensional stabiliy.

·Water proof for various industrial and civil engineerings.

·Underground water proof and damp proof for industrial and civil

engineering, and water proof for indoor swimming pool and fire pool

etc.

Application Range

·Water proof for municipal engineering such as subway, tunnel,

concrete road surface, bridge surface, sewage works and refuse

landfill etc.

·Water proof for water conservancy facilities like canal and water

pool etc .

Application range for various filler base and surface sheet

material:

·Polyester felt filler base elastic modified bituminous water proof

sheet material is appropriate to the roof and underground water

proof engineerings of industrial and civil engineering projects.

·Water proof type Ⅱ is appropriate to roof type Ⅰ and Ⅱ and

underground water proof projects.

·Glass fiber reinforced polyester filler base sheet material is

appropriate to mechanically-mounted single layer water proof, but

must pass the wind load test.

·Glass fiber felt filler base sheet material is appropriate to the roof

of structurally stable building and suitable for underground water

proof project.

·Exposed surface is suitable to have water proof sheet material

with non-transparent mineral particle as upper surface isolating

material.

·The water proof sheet material with find sand as surface

isolationg material is appropriate to underground constructioin

project.

- Q: Can a waterproofing membrane be used on roofs with rooftop gardens?

- Yes, a waterproofing membrane can be used on roofs with rooftop gardens. The membrane serves as a protective layer that prevents water from seeping into the underlying structure, ensuring that the rooftop garden remains dry and well-maintained.

- Q: Does a waterproofing membrane require any special cleaning or maintenance procedures?

- Yes, a waterproofing membrane does require special cleaning and maintenance procedures. While it is designed to be resistant to water and other elements, regular maintenance is important to ensure its longevity and effectiveness. The specific cleaning and maintenance procedures may vary depending on the type of waterproofing membrane used, but generally, it is recommended to keep the membrane clean and free from debris, such as leaves, dirt, or other foreign objects. This can be done by regularly sweeping or gently washing the surface with water and a mild detergent if necessary. Additionally, it is important to inspect the membrane regularly for any signs of damage, such as tears, cracks, or loose seams. Any such issues should be addressed promptly to prevent water infiltration and further damage. In some cases, specialized cleaning products or treatments may be recommended by the manufacturer or installer of the waterproofing membrane. It is important to follow their guidelines and recommendations to ensure the best care and maintenance for the specific membrane used. Overall, regular cleaning and maintenance of a waterproofing membrane will help to extend its lifespan and ensure its continued effectiveness in protecting the underlying structure from water damage.

- Q: Can a waterproofing membrane be used on precast plastic surfaces?

- Precast plastic surfaces can indeed benefit from the use of a waterproofing membrane. These membranes serve the purpose of establishing a shield against moisture and can be utilized on various surfaces such as concrete, metal, and plastic. By correctly implementing a waterproofing membrane, water infiltration is prevented, thus guaranteeing the long-lasting and resilient nature of the precast plastic surface. To ensure proper adhesion and effectiveness, it is crucial to select a waterproofing membrane that is compatible with plastic and adhere to the guidelines provided by the manufacturer during application.

- Q: Sbs waterproof sheet and app coil how to see it

- At present, asphalt waterproofing membrane products in the domestic waterproof engineering applications, SBS, APP modified asphalt waterproofing membrane and asphalt composite tire waterproofing membrane applications accounted for more than 80% of the former SBS, APP modified asphalt waterproofing membrane in the quality And the price should be higher than the latter, is used for national one or two fortification of the permanent industrial and civil key projects in the high-end waterproof products, and asphalt composite tire waterproofing membrane is basically used for three or four fortification General civil engineering in the general product. Because the asphalt waterproofing membrane products in the appearance of the same basic, for the prevention of fish and pearl marketing and marketing, European products in the characteristics of these two types of products and identification methods to be analyzed. The following are the same as the

- Q: How does a waterproofing membrane handle joint movement?

- A waterproofing membrane is designed to accommodate joint movement by being flexible and elastic. It can stretch and contract along with the joints, ensuring that there are no gaps or cracks through which water can penetrate. This flexibility allows the membrane to maintain its integrity and effectiveness even when the structure experiences movement due to factors like temperature changes or settling.

- Q: Can a waterproofing membrane be used for balconies or decks?

- Yes, a waterproofing membrane can be used for balconies or decks. It is a common solution to prevent water damage and ensure the longevity of these outdoor structures.

- Q: Pvc waterproof membrane of the scope of application

- PVC polymer waterproofing membrane Features: 1, PVC waterproofing membrane tensile strength, elongation is good, thermal size change rate is small; 2, anti-aging, resistant to ultraviolet radiation, chemical resistance, resistance to root penetration;

- Q: Are waterproofing membranes resistant to acid exposure?

- Waterproofing membranes can vary in their resistance to acid exposure depending on the specific type of membrane being used. Some waterproofing membranes are designed to be resistant to acid exposure, while others may not be. It is crucial to carefully select the appropriate waterproofing membrane for the specific application and environment where acid exposure may be a concern. It is also advisable to consult with manufacturers or industry experts to determine the best waterproofing membrane solution for acid-prone areas.

- Q: Can waterproofing membranes be painted over?

- Yes, waterproofing membranes can be painted over. However, it is important to use a paint that is compatible with the membrane material and to ensure that the membrane is clean and dry before painting. Additionally, it is advisable to consult the manufacturer's guidelines or seek professional advice to ensure proper adhesion and longevity of the painted surface.

- Q: Can a waterproofing membrane be used on copper surfaces?

- Yes, a waterproofing membrane can be used on copper surfaces. Copper surfaces can be susceptible to corrosion and damage from moisture, so applying a waterproofing membrane can provide an added layer of protection. The membrane will create a barrier that prevents water and moisture from penetrating the copper surface, helping to prevent corrosion and prolong the lifespan of the copper material. It is important to choose a waterproofing membrane that is compatible with copper to ensure proper adhesion and effectiveness. Additionally, proper surface preparation and application techniques should be followed to ensure a successful waterproofing solution for copper surfaces.

Send your message to us

PMB-741 Elastomer (SBS) Modified Bituminous Waterproof Sheet Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords