EPDM Waterproofing Roof Membrane

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

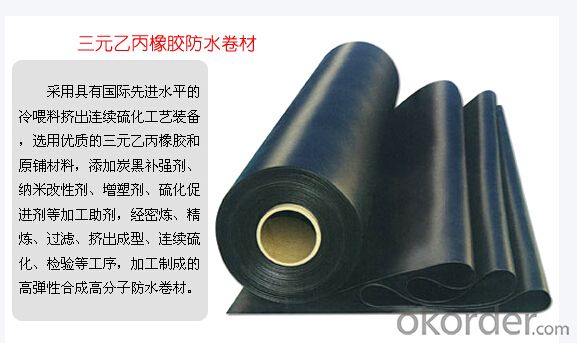

EPDM waterproofing roofing membrane

1. Introduction:

2. Features:

Excellentphysical and mechanical performance

Hightearing resistance

Gooddeformation adaptability

High puncture resistance

Highaging resistance

UVresistance

3. Application:

Roofs, Basement, Toilets

Industrial and civil building waterproofing

Geosynthetic liner for swimming pool, channels, irrigation system

Especially suitable for projects with high requirements in durability, anti-corrosion and deformation

4. Specification:

Type | EPDM Waterproof Membrane | |||

Material | EPDM Rubber | |||

Thickness | 1.0mm | 1.2mm | 1.5mm | 2.0mm |

Size | 1.2m(width) * 20m(length)/roll | |||

Type | Vulcanized | |||

Pattern | Non-reinforced(homogeneous) | |||

Packing | 24sqm--80sqm/roll, with plastic bag | |||

Color | Black | |||

Application | Roofs, basement, pond, Lake, steel structure roof, swimming pool, underground, tunnel, etc | |||

5. Some photos:

- Q: Can a waterproofing membrane be installed on vertical surfaces without causing sagging or drooping?

- Installing a waterproofing membrane on vertical surfaces without causing sagging or drooping is possible. The key lies in ensuring proper installation techniques and the use of suitable materials. To begin with, it is crucial to choose a high-quality waterproofing membrane designed specifically for vertical applications. These membranes are typically more rigid and offer better adhesion properties, enabling them to firmly adhere to vertical surfaces without sagging. Next, surface preparation plays a vital role in establishing a strong bond between the membrane and the vertical surface. It is important to thoroughly clean the surface, removing any debris, and properly prime it before applying the membrane. This step creates a solid foundation for the membrane and prevents any potential sagging or drooping. In addition, it is essential to follow proper installation techniques. Applying the membrane smoothly and evenly, without excessive stretching or folding, is key to avoiding sagging. Moreover, any seams or overlaps in the membrane should be carefully sealed to maintain a watertight barrier. Furthermore, it is recommended to use mechanical fixings like screws or nails to secure the membrane in place. These fixings provide additional support and help prevent sagging over time. In conclusion, by selecting the right materials, properly preparing the surface, and employing careful installation techniques, it is possible to install a waterproofing membrane on vertical surfaces without causing sagging or drooping.

- Q: Does a waterproofing membrane require any special tools for installation?

- Yes, installing a waterproofing membrane typically requires special tools such as a trowel, brush or roller for application, utility knife for cutting the membrane, and a heat gun for seam sealing.

- Q: Can a waterproofing membrane be used in tunnels?

- Indeed, tunnels can indeed employ a waterproofing membrane. These membranes are frequently utilized in tunnels to thwart water infiltration and safeguard the structure from water-related harm. Generally composed of materials like bitumen, PVC, or polyurethane, these membranes possess impermeability to water as a core characteristic. When properly applied, a waterproofing membrane can act as a formidable barrier against water infiltration, thereby preserving the tunnel's integrity and avoiding expensive structural impairment. Furthermore, apart from their water-resistant properties, waterproofing membranes also provide defense against other substances like chemicals and gases, rendering them a versatile remedy for both tunnel construction and upkeep.

- Q: Are waterproofing membranes resistant to corrosion?

- Yes, waterproofing membranes are resistant to corrosion. These membranes are specifically designed to provide a barrier against water, moisture, and other corrosive elements. They are made from materials that are not prone to corrosion, such as synthetic polymers like PVC or TPO, or rubberized asphalt. These materials have excellent resistance to water and moisture, as well as to chemicals and other corrosive substances. Therefore, when properly installed and maintained, waterproofing membranes can effectively protect structures against corrosion and extend their lifespan.

- Q: Can a waterproofing membrane be used in fountains or water features?

- Yes, a waterproofing membrane can be used in fountains or water features. Waterproofing membranes are designed to create a barrier that prevents water from seeping through, making them ideal for applications where water containment is essential, such as fountains or water features.

- Q: Can waterproofing membranes be used on metal roofs?

- Yes, waterproofing membranes can be used on metal roofs. These membranes are designed to create a protective barrier against water infiltration, and they can be applied to various roofing materials, including metal. Waterproofing membranes provide an effective solution to prevent leaks and extend the lifespan of metal roofs.

- Q: Can waterproofing membranes be used in wet areas like bathrooms?

- Yes, waterproofing membranes can indeed be used in wet areas like bathrooms. In fact, it is highly recommended to use waterproofing membranes in bathroom areas to prevent water damage and leakage. These membranes are specifically designed to create a barrier against moisture, ensuring that water does not seep through the walls, floors, or other surfaces of the bathroom. By applying a waterproofing membrane, you can effectively protect the underlying structure from water damage, mold growth, and other issues caused by prolonged exposure to moisture. This is especially important in wet areas like bathrooms where water is constantly present. Waterproofing membranes are available in various forms such as sheet membranes, liquid membranes, and even pre-formed shower trays. They can be applied to walls, floors, shower enclosures, and other surfaces to create a watertight seal. It is crucial to properly install and maintain the waterproofing membrane as per manufacturer guidelines to ensure its effectiveness and longevity. Therefore, if you are considering renovating or building a bathroom, using waterproofing membranes is highly recommended to ensure a durable and moisture-resistant space.

- Q: Is a waterproofing membrane resistant to saltwater or salt damage?

- Yes, a waterproofing membrane is typically resistant to saltwater or salt damage. Waterproofing membranes are designed to provide a barrier against water and moisture, and they are commonly used in various applications where exposure to saltwater or salt is expected, such as in marine environments or near coastal areas. These membranes are often made from materials that are specifically formulated to withstand the corrosive effects of saltwater or salt. Additionally, the installation of a waterproofing membrane includes proper preparation and sealing techniques to ensure its resistance to saltwater or salt damage. However, it is important to note that the specific resistance of a waterproofing membrane to saltwater or salt damage may vary depending on the type and quality of the membrane used. Therefore, it is recommended to consult with a professional or manufacturer to ensure the appropriate membrane is selected for the specific application and environment.

- Q: Can a waterproofing membrane be used for a planter box waterproofing?

- Yes, a waterproofing membrane can be used for planter box waterproofing. The membrane helps to prevent water from seeping through the planter box and causing damage to the surrounding structures. It acts as a barrier between the soil and the planter box, ensuring that water stays contained within the box.

- Q: Can a waterproofing membrane be used for below-grade applications?

- Yes, a waterproofing membrane can be used for below-grade applications. It is commonly used in construction projects to prevent water penetration and protect the foundation of below-ground structures such as basements and underground parking garages.

Send your message to us

EPDM Waterproofing Roof Membrane

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords