Geomembrane Epdm

Geomembrane Epdm Related Searches

Firestone Geomembrane Epdm Firestone Epdm Geomembrane Epi Geomembrane Geomembrane Hdpe Geomembranes Conductive Geomembrane Bgm Geomembrane Pe Geomembrane Geomembrane In Hdpe Geomembrane Machine Rpe Geomembrane Plastic Geomembrane Geomembrane Systems Epdm Lining Geomembrane Etanche Geomembrane Pdf Geomembrane Containment Geomembrane Material Permeable Geomembrane Pvc Geomembrane Gse Geomembrane Geocomposite Membrane Geomembrane Thickness Geomembrane Drainage Welding Geomembrane Gse Hdpe Geomembrane Tpo Geomembrane Geomembrane Products Geomembrane Materials Distributor GeomembraneGeomembrane Epdm Supplier & Manufacturer from China

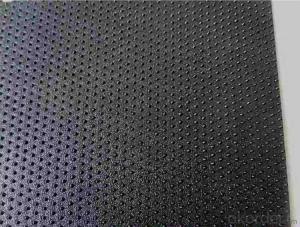

Geomembrane EPDM is a type of synthetic rubber membrane that is widely used in various industries due to its exceptional durability, flexibility, and resistance to UV radiation, chemicals, and temperature fluctuations. This high-performance material is manufactured using ethylene, propylene, and diene monomers, which contribute to its outstanding properties and make it suitable for a range of applications.The Geomembrane EPDM is commonly utilized in civil engineering projects such as landfills, reservoirs, canals, and ponds, where it serves as a waterproofing and protective barrier. It is also employed in the construction of rooftop gardens, where it prevents water infiltration and protects the underlying structure. Additionally, this versatile product is used in the agriculture sector for pond lining and in the mining industry for tailings management. Its ability to withstand harsh environmental conditions and resist degradation makes it an ideal choice for long-term projects.

Okorder.com is a leading wholesale supplier of Geomembrane EPDM, offering a vast inventory of this high-quality product to cater to the needs of various industries. With a strong commitment to customer satisfaction, Okorder.com ensures that the Geomembrane EPDM is available at competitive prices and is delivered promptly to meet the demands of clients worldwide.

Hot Products