EPDM High Polymer Waterproofing Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

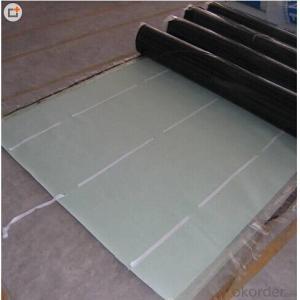

A high polymer membrane is a type of synthetic sheet material made from high-performance polymers, such as PVC (polyvinyl chloride), TPO (thermoplastic polyolefin), or EPDM (ethylene propylene diene monomer). These membranes are known for their flexibility, durability, and excellent waterproofing properties, making them widely used in construction and industrial applications.

Description:

1.EPDM Waterproof Membrane / Roofing Material / Sheets Roofing

2.High tensile strength.

3.Good elongation.

4.UV resistant.

5.Anti-corrosion.

Main features:

1.Excellent anti-aging performance, service life can reach 50 years;

2.High elongation, high tensile strength, heat treatment size change small;

3.Plant root penetration resistance is good

4.Good low temperature flexibility

5.Application is convenient, overlapping is firm and reliable, no environmental pollution;

6.Resistance to chemical corrosion, can be applied to special places;

7.Maintenance is convenient, the cost is low.

Application:

1. Make sure the base surface smooth, clean and dry(Moisture<9%), then paint the delicated agent on the base surface. Start application till it is dry.

2. Reinforce the parts which are easy to leak, such as seam, hole, channel, wall, pipe and corner.

3. Application Method: Lay the membrane directly. Be careful to control the overlaps of the long side and short side.

4. After application, a careful inspection is required. Make sure there is no air bubble, no fold, no falling away etc to guarantee the waterproof life.

FAQ:

Q:Can we get some samples before place order?

A:We can send the free samples to you by freight collect.

Q:How many years can your PVC membrane guarantee?

A:We will guarantee the quality for 5 years at least.

Q:Which countries you ever export the product?

A:We export the PVC membrane to South Africa, Middle east and even European countries.

Images:

- Q: Can waterproofing membranes be applied in cold weather?

- Yes, waterproofing membranes can be applied in cold weather. However, it is important to ensure that the manufacturer's instructions are followed regarding temperature limitations and proper installation techniques. Cold weather may affect the curing and adhesion process, so additional precautions and proper heating or insulation methods may be necessary during the application.

- Q: Can a waterproofing membrane be used for underground communication vaults?

- Underground communication vaults, usually constructed from concrete or other vulnerable materials, can benefit from the use of a waterproofing membrane. By applying this membrane to the outer surface of the vault, water infiltration can be prevented, safeguarding the vault and its contents. Acting as a barrier, the waterproofing membrane not only defends against water damage but also provides protection against various hazards, including moisture, chemicals, and soil gases. To guarantee its efficiency and long-lasting strength, it is crucial to select a top-notch waterproofing membrane that is specifically designed for underground structures.

- Q: SBS waterproofing membrane how to sample

- SBS modified asphalt waterproofing membrane, APP modified asphalt waterproofing membrane: the same manufacturers, the specifications are not more than 10000m2 for a number of qualified qualified coil, each batch of random 1

- Q: What is the lifespan of a waterproofing membrane in extreme weather conditions?

- The lifespan of a waterproofing membrane in extreme weather conditions can vary depending on various factors such as the quality of the membrane, the intensity and duration of the weather conditions, and the maintenance and care provided to the membrane. In general, high-quality waterproofing membranes designed for extreme weather conditions can have a lifespan of 20-30 years or more. These membranes are typically made from durable materials such as modified bitumen, PVC, EPDM, or TPO, which are specifically engineered to withstand harsh weather elements. However, it is important to note that extreme weather conditions, such as heavy rain, intense sunlight, freezing temperatures, or strong winds, can accelerate the wear and tear of the membrane. For example, prolonged exposure to UV radiation can cause the membrane to degrade and lose its effectiveness over time. Regular maintenance and inspections are crucial to prolonging the lifespan of the waterproofing membrane in extreme weather conditions. By promptly addressing any signs of damage, such as cracks, tears, or leaks, and conducting regular cleaning and resealing, the membrane can be better protected against the harsh effects of extreme weather. Furthermore, proper installation techniques and following manufacturer's guidelines are essential to ensure the longevity of the waterproofing membrane. Hiring experienced professionals who are familiar with installing membranes in extreme weather conditions can greatly contribute to the durability and lifespan of the membrane. Ultimately, while a high-quality waterproofing membrane can withstand extreme weather conditions for several decades, it is important to monitor its condition regularly, provide proper care and maintenance, and promptly address any issues that arise to maximize its lifespan.

- Q: Can a waterproofing membrane be used for underground fuel storage tanks?

- Underground fuel storage tanks can benefit from the application of a waterproofing membrane. This membrane serves as a barrier, preventing water and moisture from infiltrating the tank and causing corrosion or leaks. Given their underground positioning, these tanks are particularly susceptible to moisture infiltration. By utilizing a waterproofing membrane, the tank's integrity and lifespan are safeguarded through the provision of a sturdy and trustworthy waterproof seal. When selecting a waterproofing membrane for fuel storage purposes, it is vital to opt for one specifically formulated to endure the harsh conditions and chemicals associated with underground fuel storage.

- Q: Where are waterproofing membranes commonly used?

- Waterproofing membranes find wide application in various scenarios, serving to thwart water infiltration and safeguard structures against moisture-induced harm. The prevalent areas where they are employed include: 1. Basements: Waterproofing membranes are extensively utilized in basements to counter water seepage via foundation walls and floors. They establish a barrier that repels water, thereby promoting a dry and inhabitable space. 2. Roofs: Roofs often make extensive use of waterproofing membranes to shield buildings against rain, snow, and other adverse elements. Positioned beneath the roofing materials, they act as a barricade, averting water penetration and ensuring roof integrity. 3. Bathrooms and wet areas: Bathrooms, showers, and other wet regions necessitate the presence of waterproofing membranes to prevent water intrusion into walls and floors. By creating an impermeable seal, they effectively thwart the growth of mold, water damage, and structural complications. 4. Balconies and terraces: Balconies, terraces, and other outdoor spaces commonly benefit from the application of waterproofing membranes. Their presence safeguards against water-induced deterioration by constituting a protective layer that bars water penetration. 5. Swimming pools: Swimming pool construction heavily relies on waterproofing membranes to prevent water leakage. By being applied to the pool shell, they provide a water-tight seal, ensuring structural integrity and preventing water seepage. 6. Tunnels and underground structures: Tunnels and underground structures employ waterproofing membranes to shield against groundwater infiltration. These membranes serve as a waterproof barrier, effectively preventing water damage and structural compromise. 7. Planter boxes and green roofs: Planter boxes and green roofs often incorporate waterproofing membranes to avert water seepage into building structures. By establishing a barrier, they retain moisture within the planter or green roof while blocking infiltration into the building. In summary, waterproofing membranes assume a vital role in diverse construction endeavors, safeguarding structures, and prolonging their lifespan by curtailing water damage and moisture-related issues.

- Q: Can a waterproofing membrane be used on tunnels with railway systems?

- Yes, a waterproofing membrane can be used on tunnels with railway systems. The membrane helps to prevent water ingress and moisture damage to the tunnel structure, ensuring the safety and longevity of the railway system.

- Q: Does a waterproofing membrane require a protective layer?

- Yes, a waterproofing membrane typically requires a protective layer. The protective layer helps to shield the membrane from various external factors, such as UV rays, weather conditions, mechanical damage, and chemical exposure, thereby enhancing its durability and longevity.

- Q: Are waterproofing membranes suitable for indoor applications?

- Yes, waterproofing membranes are suitable for indoor applications. They are commonly used in areas such as bathrooms, basements, and kitchens to prevent water damage and moisture penetration. Waterproofing membranes provide an effective barrier against water and can help protect the structural integrity of buildings in indoor environments.

- Q: Can a waterproofing membrane be used for airport runways?

- Yes, a waterproofing membrane can be used for airport runways. Airport runways are subjected to a significant amount of wear and tear due to heavy aircraft traffic, weather conditions, and potential fuel spills. A waterproofing membrane can serve as a protective barrier against water infiltration, which can lead to runway deterioration and damage. It can also prevent the penetration of fuel, oil, and other chemicals that can weaken the runway structure. Additionally, a waterproofing membrane can help to prolong the lifespan of the runway by reducing the effects of freeze-thaw cycles and preventing the formation of cracks and potholes. Overall, the use of a waterproofing membrane can enhance the durability and safety of airport runways, ensuring smooth operations and minimizing maintenance costs.

Send your message to us

EPDM High Polymer Waterproofing Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords