EPDM Waterproofing Membrane For Construction Field

- Loading Port:

- Qingdao, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 M2 m²

- Supply Capability:

- Above 10000000M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Specification for EPDM Waterproofing Membrane:

|

Type |

EPDM Waterproof Membrane | |||

|

Material |

EPDM Rubber | |||

|

Thickness |

1.0mm |

1.2mm |

1.5mm |

2.0mm |

|

Size |

1.2m(width) * 20m(length)/roll, Weldale could 4m width | |||

|

Type |

Vulcanized & Weldable | |||

|

Pattern |

Non-reinforced(homogeneous) | |||

|

Packing |

24sqm--80sqm/roll, with plastic bag | |||

|

Color |

Black | |||

|

Application |

Roof, basement, pond, Lake, steel structure roof, swimming pool, underground, tunnel, etc | |||

Product Features of EPDM Waterproofing Membrane:

1. the excellent anti-aging, in the long term light, humidity, cold use of the natural

environment, small changes in physical properties, used in the temperature:

From -50 degree Celsius to +80degree Celsious.

2.with outstanding ozone resistance, resistance to ultraviolet and atmospheric corrosion

of many chemical corrosive substances.

3. high tensile strength, high elongation, high flexibility, capable of sustaining

a puncture of hard material, good anti-crack, high adaptability of the grass roots'

contraction and the crack and deformation, and give full play to extend the

performance, playing the role of waterproofing.

4.long lifetime, high durability can achieve more than 25 years.

5.the cold construction operation, no environment pollution and simple operation.

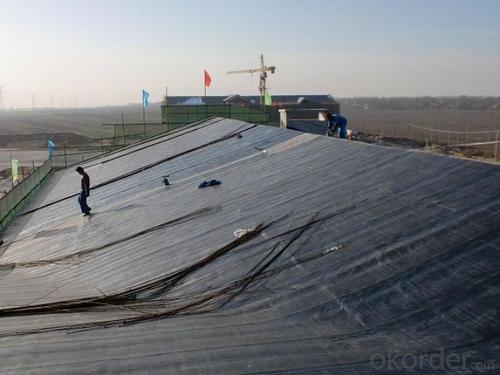

Application Pictures of EPDM Waterproofing Membrane:

- Q: Can a waterproofing membrane be used for bathrooms or showers?

- Bathrooms or showers can benefit greatly from the use of a waterproofing membrane. It is highly advisable to apply this protective layer in order to avoid any water leaks or harm to the underlying structure. Typically, the membrane is spread across the walls and floor of the bathroom or shower area, creating a barrier that stops water from penetrating through. This safeguard not only shields the surrounding areas from moisture, but it also prevents the growth of mold and mildew. Moreover, a waterproofing membrane is instrumental in extending the lifespan of the bathroom or shower by preventing water damage and deterioration. All in all, employing a waterproofing membrane is an efficient solution to ensure the resilience and longevity of these spaces.

- Q: Are waterproofing membranes resistant to frost damage?

- Yes, waterproofing membranes are generally resistant to frost damage. Waterproofing membranes are designed to be durable and able to withstand various weather conditions, including freezing temperatures. They are typically made from materials such as modified bitumen, PVC, EPDM, or TPO, which have excellent resistance to frost and other environmental factors. These materials are engineered to remain flexible and elastic even in cold temperatures, ensuring that the waterproofing membrane remains intact and effective in preventing water penetration. Additionally, proper installation techniques and maintenance can further enhance the resistance of waterproofing membranes to frost damage.

- Q: Can a waterproofing membrane be used in elevator pits or sump pits?

- Certainly! Below is a rewritten version of the passage: Indeed, elevator pits or sump pits can benefit from the utilization of a waterproofing membrane. These pits are prone to water infiltration, but the application of a waterproofing membrane can effectively prevent water seepage. By acting as a barrier, the membrane stops any water from entering the pit and causing harm to the elevator or pumping system. Consequently, this safeguards the longevity and integrity of the elevator or pump. Moreover, the waterproofing membrane also safeguards the surrounding structures from water damage. Thus, it is crucial to select a suitable waterproofing membrane that is specifically designed for below-ground applications and possesses the necessary properties to withstand the unique conditions within an elevator or sump pit.

- Q: Can a waterproofing membrane be used on adobe block surfaces?

- Yes, a waterproofing membrane can be used on adobe block surfaces. Adobe blocks are made from a mixture of clay, sand, and straw, which can be susceptible to water damage. Applying a waterproofing membrane can help prevent water penetration and protect the adobe blocks from moisture-related issues such as cracking, erosion, or mold growth. It is important to ensure that the waterproofing membrane is compatible with adobe surfaces and follows the manufacturer's guidelines for application. Additionally, proper surface preparation and repair of any existing damage is crucial before applying the membrane to ensure its effectiveness.

- Q: Can a waterproofing membrane be used for underwater structures?

- Indeed, underwater structures can benefit from the utilization of a waterproofing membrane. These membranes have been specifically engineered to create a formidable barrier against water infiltration, rendering them appropriate for various applications, including underwater structures. Typically composed of robust materials like reinforced PVC or rubber, these membranes possess exceptional water resistance capabilities and effectively safeguard submerged surfaces by forming a reliable seal. Whether it be a swimming pool, underwater tunnel, or offshore platform, the implementation of a waterproofing membrane can effectively thwart water ingress and preserve the structural integrity. Nonetheless, it is crucial to ascertain that the chosen waterproofing membrane has been meticulously crafted and thoroughly tested for underwater applications to guarantee optimal performance and longevity.

- Q: Can a waterproofing membrane be used on tunnels with seismic protection systems?

- Tunnels equipped with seismic protection systems can indeed benefit from the use of a waterproofing membrane. It is strongly advised to employ such a membrane in order to avoid water infiltration and subsequent harm to the tunnel's integrity. Seismic protection systems are engineered to absorb and dissipate the seismic energy released during an earthquake, guaranteeing the tunnel's safety and stability. However, these systems do not provide any defense against water ingress. By incorporating a waterproofing membrane, the tunnel can be shielded from potential water leaks and seepage, which can result in reinforcement corrosion, concrete deterioration, and overall structural impairment. It is crucial to opt for a waterproofing membrane specifically designed for tunnel use, taking into account qualities such as flexibility, durability, and resistance to seismic-induced movement. Moreover, precise detailing and installation techniques must be employed to ensure a seamless and efficient waterproofing system that complements the tunnel's seismic protection measures.

- Q: Are there any specific tools or equipment required for installing a waterproofing membrane?

- Yes, there are specific tools and equipment required for installing a waterproofing membrane. Some common tools include a trowel, utility knife, paint roller, brush, and caulking gun. Additionally, a heat gun or torch may be needed for certain types of membranes that require heat activation. It is important to follow the manufacturer's instructions and recommendations for the specific membrane being installed to ensure proper installation and effectiveness.

- Q: Can a waterproofing membrane be used for balconies or decks?

- Yes, a waterproofing membrane can be used for balconies or decks. It is a common solution to prevent water damage and ensure the longevity of these outdoor structures.

- Q: How does a waterproofing membrane handle movement or settling of a building?

- A building's movement or settling can be accommodated by a waterproofing membrane in several ways. Firstly, the membrane is typically installed in a manner that allows it to stretch or flex as the building moves. This elasticity ensures that the membrane remains intact and continues to provide a watertight seal, even if the structure shifts or settles. In addition, waterproofing membranes often include reinforcement materials, such as fabrics or fibers, which enhance their ability to withstand movement. These reinforcements help distribute the stress or strain caused by building movement across a larger area, reducing the risk of tears or failures in the membrane. Moreover, certain waterproofing membranes are designed with built-in features that can handle significant movement. For instance, some membranes possess special "crack-bridging" properties, enabling them to span small cracks that may develop in the building's substrate due to settling. This ensures that the membrane remains effective, even if the structure sustains minor damage. In cases where a building is expected to experience significant movement or settling, specialized waterproofing systems, such as joint sealants or expansion joints, may be used in conjunction with the membrane. These systems are specifically designed to handle large or dynamic movements, providing additional protection against water infiltration. Overall, careful design and installation of a waterproofing membrane enable it to effectively handle a building's movement or settling. Its elasticity, reinforcement materials, and additional features ensure that it maintains a watertight seal, even when faced with structural shifts or settlement.

- Q: Can waterproofing membranes be used on elevator pits?

- Yes, waterproofing membranes can be used on elevator pits. Elevator pits are prone to water infiltration, and using waterproofing membranes can help prevent water damage and corrosion in the pit area. The membranes create a barrier that prevents water from seeping into the pit, ensuring its dryness and structural integrity.

1. Manufacturer Overview

| Location | Beijing, China |

| Year Established | 1998 |

| Annual Output Value | Above US$ 30 Million |

| Main Markets | Mid East; Eastern Europe; North America; Southeast Asia |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | Above 50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 600,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Negotiated |

Send your message to us

EPDM Waterproofing Membrane For Construction Field

- Loading Port:

- Qingdao, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 M2 m²

- Supply Capability:

- Above 10000000M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords