Red Guard Waterproofing Membrane

Red Guard Waterproofing Membrane Related Searches

Redgard Waterproofing Membrane Waterproof Geomembrane Geomembrane Waterproofing Paintable Waterproof Membrane Bentonite Waterproofing Membrane Waterproof Membrane For Decks Mapei Waterproofing Membrane Damp Proof Membrane Concrete Foundation Waterproofing Membrane Waterproofing Membrane Philippines Residential Waterproofing Waterproofing Geomembrane Liner Liquid Rubber Membrane Waterproof Resin Waterproof Material Bitumen Roofing Membrane Waterproof Seal Mel Rol Waterproofing Waterproofing Wet Areas Commercial Waterproofing Material Waterproofing Spray Waterproof Sealer Permeable Geomembrane Plastomeric Waterproofing Materials Waterproofing Inspection Waterproof Paint Mesh Retaining Wall Waterproof Thermal Blanket Reinforced Geomembrane Waterproofing HomesRed Guard Waterproofing Membrane Supplier & Manufacturer from China

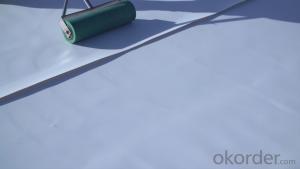

Red Guard Waterproofing Membrane is a high-quality product designed to provide effective waterproofing solutions for various applications. This membrane is made from advanced materials that ensure durability and long-lasting performance, making it an ideal choice for both residential and commercial projects. The product is known for its ability to withstand harsh weather conditions and provide a seamless barrier against water infiltration.The Red Guard Waterproofing Membrane is widely used in various scenarios, such as roofing, basements, and foundation walls, where waterproofing is a critical requirement. It is particularly effective in areas prone to heavy rainfall or flooding, as it forms a robust barrier that prevents water from seeping through. The membrane is easy to install and can be applied to both new constructions and existing structures, making it a versatile solution for a range of waterproofing needs.

Okorder.com is a reputable wholesale supplier of Red Guard Waterproofing Membrane, offering a vast inventory to cater to the needs of contractors, builders, and homeowners. As a trusted source for this product, Okorder.com ensures that customers receive high-quality materials at competitive prices, backed by excellent customer service and support. By partnering with Okorder.com, customers can be confident that they are investing in a reliable and effective waterproofing solution for their projects.

Hot Products