Root-puncture Resistant Waterproofing Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

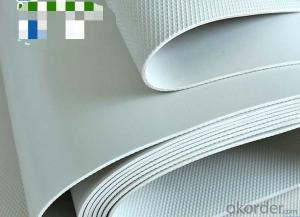

1.Structure of Root-puncture Resistant Waterproofing Membrane:

Because the traditional waterproofing materials as well as ordinary polymer waterproof material, all kinds of waterproof coating can meet the requirements of building planting system, because these materials do not have root resistance, it is easy to plant root penetration, the building damage and leakage, directly led to the failure of the "planting green building system. And a PVC duplex root puncture resistant waterproofing materials in copper base as root membrane resistance, resistance to plants with long roots or rhizomes puncture performance, strong cohesive force, good stability, low temperature flexibility and good heat resistance, chemical corrosion resistance and radiation resistance is strong, for more than 20 years still showed good resistance waterproof performance.

2.Main Features of Root-puncture Resistant Waterproofing Membrane:

Waterproof and prevent plant root through the dual function.

Durable, resistant to cough up, tear resistance, resistance to fatigue

Tensile strength is high, the change of asphalt coating cover thickness is big

Corrosion resistance, resistance to mildew, good corrosion resistance

3.Specification of Root-puncture Resistant Waterproofing Membrane:

| Tensile Strength | 800N/5CM | |||

| Elongation at break | 40% | |||

| Heat resistance | 115℃ | |||

| Low temperature resistant | -35℃ | |||

| Thickness | ≥4mm |

4.Root-puncture Resistant Waterproofing Membrane Images;

- Q: Can a waterproofing membrane be used on roofs with slope?

- Roofs with slope can use a waterproofing membrane. It is commonly applied on sloped roofs to add an extra layer of protection against water infiltration. The membrane is typically placed beneath the roofing materials and acts as a barrier to stop water from seeping into the roof structure. This is particularly crucial for sloped roofs as water runoff is faster and may lead to leaks or damage. The waterproofing membrane is designed to be flexible and is able to adapt to the roof's slope without compromising its effectiveness. Moreover, it also enhances the roof's durability and lifespan by preventing moisture-related problems like rot or mold growth.

- Q: Are waterproofing membranes resistant to water vapor transmission?

- Yes, waterproofing membranes are resistant to water vapor transmission. These membranes are designed to create a barrier that prevents water from penetrating through them. They are typically made from materials that are impermeable to water, such as rubber, plastic, or bitumen. This means that they effectively block the passage of liquid water, preventing it from seeping into the underlying structure. However, it is important to note that while waterproofing membranes can effectively resist water vapor transmission, they may not completely eliminate it. Some amount of water vapor may still pass through the membrane, but it is significantly reduced compared to other materials that are not designed for waterproofing purposes.

- Q: Can a waterproofing membrane be used on gypsum board surfaces?

- Yes, a waterproofing membrane can be used on gypsum board surfaces. Gypsum board, also known as drywall, is a common material used in interior construction. While it is not inherently waterproof, applying a waterproofing membrane can help protect the gypsum board from moisture damage. A waterproofing membrane is a thin layer of material that is applied to the surface of the gypsum board. It forms a barrier that prevents water from seeping into the board and causing it to deteriorate or mold. It can be used in areas where moisture is present, such as bathrooms, kitchens, laundry rooms, or basements. Before applying a waterproofing membrane, it is important to prepare the gypsum board surface properly. This may involve cleaning the surface, patching any holes or cracks, and ensuring the board is dry and free of dust. Once the surface is ready, the waterproofing membrane can be applied according to the manufacturer's instructions. It is worth noting that while a waterproofing membrane can provide some protection against moisture, it is not a guarantee against water damage. It is always important to address the source of water intrusion and ensure proper drainage and ventilation in any area prone to moisture. Additionally, it is recommended to consult with a professional or follow the manufacturer's recommendations when choosing and applying a waterproofing membrane to gypsum board surfaces.

- Q: Can a waterproofing membrane be used on tunnels with subway systems?

- Yes, a waterproofing membrane can be used on tunnels with subway systems. Waterproofing membranes are commonly used in underground construction projects, including tunnels and subway systems, to prevent water infiltration. These membranes act as a protective barrier, preventing water from entering the tunnel and causing damage to the infrastructure. By using a waterproofing membrane, the tunnel structure can be effectively protected and the subway system can operate safely and efficiently.

- Q: Can a waterproofing membrane be used for crawl spaces or basements?

- Yes, a waterproofing membrane can be used for crawl spaces or basements. In fact, it is one of the most effective methods to prevent water infiltration and moisture issues in these areas. Waterproofing membranes are designed to create a protective barrier against water, preventing it from seeping into the crawl space or basement. They are typically made from durable materials such as rubber, PVC, or polyethylene, which are resistant to water penetration. These membranes are installed on the walls and floors of the crawl space or basement, creating a watertight seal. This helps to keep the area dry, prevent water damage, and reduce the risk of mold and mildew growth. Additionally, waterproofing membranes can also act as a vapor barrier, preventing moisture from evaporating from the ground and entering the crawl space or basement. Overall, using a waterproofing membrane is a recommended solution for maintaining a dry and healthy crawl space or basement.

- Q: What are the different types of waterproofing membranes?

- Construction and building projects commonly utilize various types of waterproofing membranes to prevent water penetration through walls, roofs, or other structures. These membranes can be applied to different surfaces. 1. Bituminous Membranes: Comprised of bitumen, polymers, and reinforcement materials like fiberglass or polyester, bituminous waterproofing membranes are frequently employed in roofing applications. They can be applied using hot or cold processes and offer outstanding waterproofing properties and durability. 2. PVC Membranes: Synthetic PVC membranes exhibit high resistance to water, chemicals, and UV radiation. They are often used in roofing applications, particularly for flat or low-slope roofs. PVC membranes are lightweight, flexible, and easy to install, boasting long-lasting waterproofing protection while being puncture and tear-resistant. 3. EPDM Membranes: Synthetic rubber EPDM membranes find common use in roofing applications. These membranes are highly durable, flexible, and resistant to UV radiation, ozone, and extreme temperatures. They can be installed as a single-ply membrane or in combination with other materials. 4. TPO Membranes: TPO membranes, a type of single-ply roofing membrane, are commonly employed in commercial and industrial settings. Composed of polymer blends and reinforcement materials, TPO membranes exhibit high resistance to water, chemicals, and UV radiation. They are lightweight, flexible, and easy to install. 5. Liquid Applied Membranes: Liquid applied membranes are an application type where the waterproofing system is initially liquid and cures to form a seamless and flexible membrane. These membranes can be made from various materials such as acrylic, polyurethane, or rubber-based compounds. They are often used for below-grade applications like basements or foundations, as well as roofs or other surfaces. To ensure effective and long-lasting waterproofing protection, it is crucial to consider the specific project requirements and consult with professionals to determine the most suitable type of waterproofing membrane.

- Q: Can a waterproofing membrane be used on sloped roofs?

- Yes, a waterproofing membrane can be used on sloped roofs. In fact, it is often recommended to use a waterproofing membrane on sloped roofs to prevent water infiltration and potential leaks. The membrane acts as a barrier, preventing water from seeping into the roof structure and causing damage. Additionally, the membrane can also help to protect the roof from other elements such as UV rays, temperature fluctuations, and mechanical stresses. It is essential to choose a waterproofing membrane that is specifically designed for sloped roofs and is compatible with the roofing material to ensure long-lasting protection.

- Q: Can a waterproofing membrane be used in showers and wet areas?

- Yes, a waterproofing membrane can be used in showers and wet areas. Waterproofing membranes are designed to provide a protective barrier against water penetration, making them ideal for use in areas that are constantly exposed to water, such as showers and wet areas.

- Q: How does a waterproofing membrane handle moisture from the ground?

- To effectively manage moisture from the ground, a waterproofing membrane is designed to create a barrier that stops water infiltration. It is typically constructed using impermeable materials like rubber, bitumen, or modified asphalt. When correctly implemented, the membrane forms a continuous, watertight layer that prevents water from seeping through the foundation or walls. Typically, the membrane is placed on the exterior side of a building's foundation, where it serves as a protective shield against groundwater. It is applied directly onto the concrete or masonry surface, forming a seamless and durable waterproofing layer. To ensure its long-term durability, the membrane is then covered with a protective layer, such as soil or backfill. In addition to being impermeable, a waterproofing membrane also incorporates features that enable it to handle moisture effectively. For example, it may include built-in channels or dimples that facilitate the drainage of water away from the foundation, preventing the accumulation of hydrostatic pressure. Some membranes even possess self-healing properties, allowing them to seal minor punctures or cracks that may develop over time. Overall, a properly installed waterproofing membrane serves as a dependable barrier against ground moisture. It safeguards the structure from water damage, prevents the growth of mold and mildew, and maintains a dry and healthy indoor environment. However, it is crucial to ensure correct installation by adhering to the manufacturer's guidelines and seeking assistance from experienced professionals to guarantee its effectiveness.

- Q: Can waterproofing membranes be used on concrete block walls?

- Concrete block walls can indeed benefit from the use of waterproofing membranes. It is actually quite common and highly advised to employ such membranes on concrete block walls in order to ward off water infiltration and potential moisture-related harm. These membranes are specifically engineered to establish a barrier against water and can be effectively applied to either the exterior or interior surface of the concrete block walls. In doing so, they furnish an added layer of safeguarding, thereby preventing moisture from penetrating the walls and causing issues such as the growth of mold, efflorescence, and the deterioration of the concrete blocks themselves. By opting for the utilization of waterproofing membranes, you can effectively ensure the long-lasting resilience and durability of your concrete block walls.

Send your message to us

Root-puncture Resistant Waterproofing Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords