High Quality SBS Waterproofing Membrane

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 M2 m²

- Supply Capability:

- ONE WEEK PER CONTAINE m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

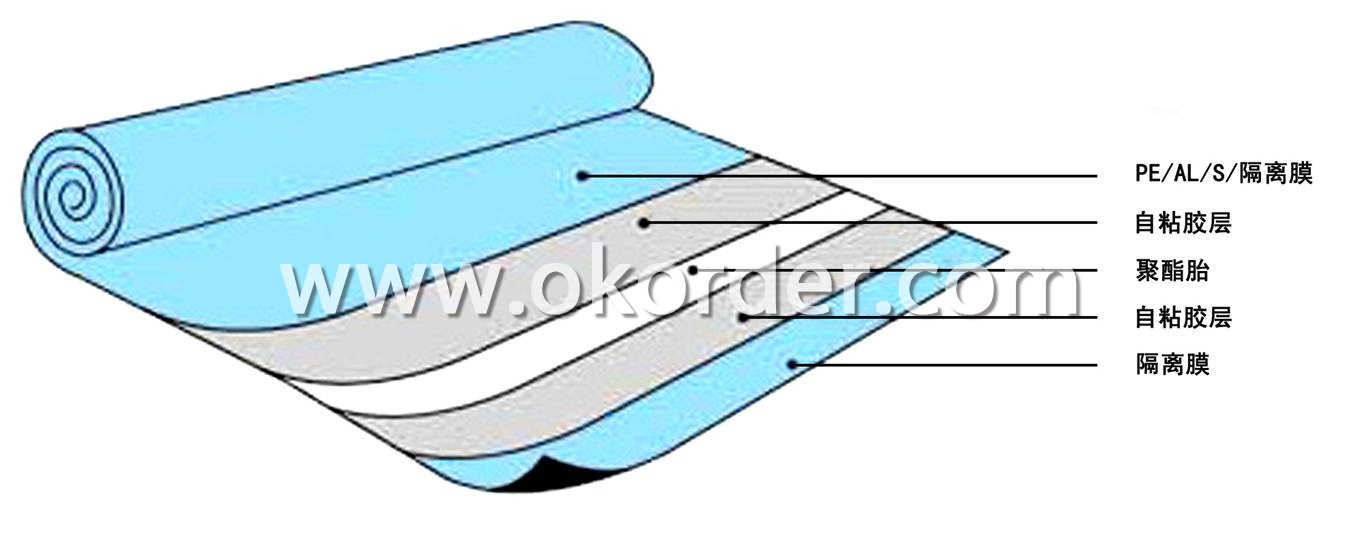

SBS modified bitumen waterproofing membrane is made by soaking the base in bitumen,or thermoplas ticityelastomer(such as styrene butadiene-SBS) modified bitumen, then covering double faces with elastomer(SBS) modified bitumen, and last finiishing the upward face with fine sands, mineral slates(or grains) or polythene membrane ect, while downward face with fine sands or polythene membrane.

Characteristics Of SBS Waterproofing Membrane :

It has good waterproofing and ageing-resistance function, not flowing at highest temperature and no crack at lowest temperature;

Easy application , no pollution, and long service life etc.

Specification of SBS/APP Polyester Waterproofing Membrane:

|

N |

ITEM |

STANDARD |

TEST RESULT |

||

|

1

|

WATER IMPERMEABILITY |

PRESSUREMpa |

>0.3 |

NO IMPERAMEABILITY |

|

|

KEEPING TIME, min |

120MIN |

||||

|

2 |

TENSION N/5cm |

≥300 |

MEET ASTM-D5147 |

||

|

3 |

FRACTURE ELONGATION,% |

≥450 |

LONGTIUDINAL550.0 TRANSVERSE 510.0 |

||

|

4 |

SOFTEN POINT |

110°C, |

MEET ASTM-D 5147 |

||

|

5 |

COLD FLEXIBILITY |

≥0(-20) |

MEET ASTM-D 5147 |

||

|

6 |

ELONGATION |

≥45 |

47 |

||

|

7 |

APP/SBS WATERPROOF MEMBRANE MEET DEMAND OF ASTM STANDARD | ||||

Usage of SBS/APP Waterproofing Membrane :

It is widely used for industry and civil building --- the waterproof and dampproof of the roofs, basements, toilets etc; and the waterproofing of bridges, parking area, tunnels, reservoir etc.

SBS modified bitumen waterproof membrane is specially suitable to the building waterproofing in cold area and to the buildings of changeable constructions while APP specially suitable to areas of high temperature and of strong sunshine.

- Q: Can a waterproofing membrane be installed in wet conditions?

- Yes, a waterproofing membrane can be installed in wet conditions. However, it is important to ensure that the surface being waterproofed is dry and free of any standing water before the installation. This is because the membrane needs a clean and dry surface to adhere properly and create an effective barrier against water. If the surface is wet, it may prevent the membrane from bonding correctly, leading to potential leaks or failures in the waterproofing system. Therefore, it is recommended to wait for the surface to dry or use appropriate methods to remove any excess moisture before installing the waterproofing membrane.

- Q: DTM.E polyester composite waterproofing membrane, cheaper than the asphalt membrane?

- Ouwei Jianke DTM.E polyester composite waterproofing membrane is the company according to GB50207-2002 "roofing quality acceptance norms", GB50108-2008 "underground engineering waterproof technical specifications", GB50208-2002 "underground waterproofing project quality acceptance norms" and Other waterproof engineering design Widely used in a new type of waterproof material,

- Q: Can a waterproofing membrane be used for a bridge deck?

- Indeed, a bridge deck can utilize a waterproofing membrane. In fact, it is customary to employ a waterproofing membrane on bridge decks to safeguard the structure against moisture infiltration, which may result in corrosion and deterioration. A waterproofing membrane acts as a protective shield, preventing water from permeating the concrete deck and ensuring the bridge's longevity and durability. Additionally, it can aid in minimizing the risk of freeze-thaw damage, which is particularly crucial in regions with severe weather conditions. All in all, the implementation of a waterproofing membrane on a bridge deck is a dependable approach to prolong its lifespan and preserve its structural integrity.

- Q: Can a waterproofing membrane be used for convention centers or exhibition halls?

- Yes, a waterproofing membrane can be used for convention centers or exhibition halls. Waterproofing membranes are commonly used in construction to protect buildings from water damage and leakage. Given the potential for water infiltration in large spaces like convention centers or exhibition halls, using a waterproofing membrane can help ensure the integrity and durability of the structure by preventing water penetration and potential damage.

- Q: Can waterproofing membranes be used on concrete stairs?

- Concrete stairs can indeed benefit from the application of waterproofing membranes. These membranes serve the purpose of establishing a safeguarding barrier, effectively shielding the concrete from water and moisture infiltration, thus averting potential harm. By implementing a waterproofing membrane on concrete stairs, one can effectively extend their longevity, impede deterioration, and minimize the requirement for expensive repairs in the future. It is vital to select a waterproofing membrane specifically crafted for concrete usage and adhere to the manufacturer's guidelines for correct application.

- Q: Can a waterproofing membrane be used for food processing facilities?

- Yes, a waterproofing membrane can be used for food processing facilities. These membranes are specifically designed to prevent water penetration and can be installed in areas where food is processed to ensure a hygienic and moisture-resistant environment.

- Q: Is a waterproofing membrane resistant to mold and mildew growth?

- Yes, a waterproofing membrane is typically resistant to mold and mildew growth. The membrane acts as a barrier against moisture, preventing it from seeping into the building materials and creating an environment for mold and mildew to thrive.

- Q: Are there any specific considerations for installing a waterproofing membrane on concrete surfaces?

- Installing a waterproofing membrane on concrete surfaces requires careful attention to several specific considerations. Firstly, it is crucial to thoroughly clean the concrete surface and remove any loose materials, oil, grease, or contaminants that could hinder the adhesion of the membrane. Failure to do so may compromise the effectiveness of the waterproofing. Secondly, it is of utmost importance to inspect the concrete surface for cracks, spalling, or other types of damage. Prior to installing the waterproofing membrane, these defects must be repaired to prevent water from penetrating through the membrane and compromising its ability to protect the concrete. Moreover, the selection of the appropriate type of waterproofing membrane is essential. There are various options available, such as sheet membranes, liquid-applied membranes, and cementitious coatings. Each type has different application methods, durability, flexibility, and resistance to substances. Therefore, it is crucial to choose the membrane that best suits the specific concrete surface and its intended use. In addition, the installation process should strictly adhere to the manufacturer's instructions. This includes applying the membrane at the recommended thickness, ensuring proper overlap and adhesion of the seams, and using any recommended primers or adhesives. Lastly, long-term maintenance and durability should be taken into consideration. Regular inspections, maintenance, and repairs are necessary to ensure the membrane remains intact and effective in preventing water penetration.

- Q: Can a waterproofing membrane be used on plastic block surfaces?

- Yes, a waterproofing membrane can be used on plastic block surfaces.

- Q: Can a waterproofing membrane be used in bridge decks or roadways?

- Yes, bridge decks and roadways can benefit from the use of a waterproofing membrane. This protective layer prevents water infiltration and increases the lifespan of the structure. Given the harsh weather conditions and heavy traffic that bridge decks and roadways face, a waterproofing membrane is essential. Water penetration can cause damage to bridge decks and roadways, including corrosion of steel reinforcements and deterioration of concrete. By applying a waterproofing membrane, a barrier is created to prevent water from seeping into the structural elements. This reduces the risk of corrosion and extends the durability of the bridge or roadway. Additionally, a waterproofing membrane can help prevent the formation of cracks and potholes, which are often caused by the freeze-thaw cycle and water penetration. By keeping the surface of the bridge deck or roadway dry, the membrane maintains its structural integrity and avoids costly repairs or premature replacement. It is important to consider factors such as material selection, installation techniques, and maintenance when using a waterproofing membrane in bridge decks or roadways. The chosen membrane should be compatible with the construction materials, and the installation process must be done correctly to ensure a watertight seal. Regular maintenance and inspections should also be done to identify any issues or damage to the membrane. This allows for timely repairs and ensures its effectiveness over time. Overall, using a waterproofing membrane in bridge decks or roadways is an efficient solution to protect against water damage and extend the lifespan of these critical infrastructure elements.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 2003 |

| Annual Output Value | Above US$ 10 Million |

| Main Markets | Europe; North America; Africa; Asia |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 50% - 100% |

| No.of Employees in Trade Department | 6- 10 people |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 100000 Square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | |

Send your message to us

High Quality SBS Waterproofing Membrane

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 M2 m²

- Supply Capability:

- ONE WEEK PER CONTAINE m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords