SBS Modified Bitumen Waterproofing Membrane

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 M2 m²

- Supply Capability:

- ONE WEEK PER CONTAINE m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

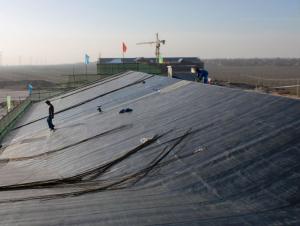

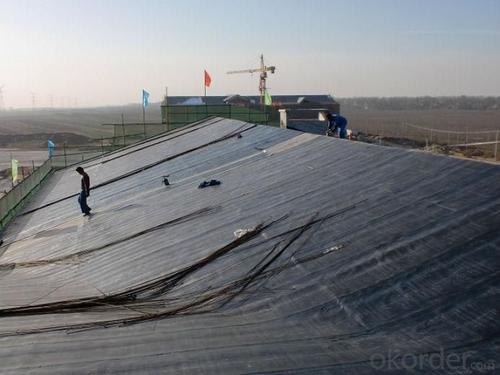

SBS modified bitumen waterproofing membrane is made by soaking the base in bitumen,or thermoplas ticityelastomer(such as styrene butadiene-SBS), modified bitumen, then covering double faces with elastomer(SBS) modified bitumen, and last finiishing the upward face with fine sands, mineral slates(or grains) or polythene membrane ect, while downward face with fine sands or polythene membrane.

Specification of SBS/APP Polyester Waterproofing Membrane:

|

N |

ITEM |

STANDARD |

TEST RESULT |

||

|

1

|

WATER IMPERMEABILITY |

PRESSUREMpa |

>0.3 |

NO IMPERAMEABILITY |

|

|

KEEPING TIME, min |

120MIN |

||||

|

2 |

TENSION N/5cm |

≥300 |

MEET ASTM-D5147 |

||

|

3 |

FRACTURE ELONGATION,% |

≥450 |

LONGTIUDINAL550.0 TRANSVERSE 510.0 |

||

|

4 |

SOFTEN POINT |

110°C, |

MEET ASTM-D 5147 |

||

|

5 |

COLD FLEXIBILITY |

≥0(-20) |

MEET ASTM-D 5147 |

||

|

6 |

ELONGATION |

≥45 |

47 |

||

|

7 |

APP/SBS WATERPROOF MEMBRANE MEET DEMAND OF ASTM STANDARD |

||||

Characteristics Of SBS/APP Waterproofing Membrane :

It has good waterproofing and ageing-resistance function, not flowing at highest temperature and no crack at lowest temperature;

Easy application , no pollution, and long service life etc.

- Q: What are the requirements for the storage of waterproofing membranes?

- Prohibited sun exposure, exposure easily deformed.

- Q: Does a waterproofing membrane require any specialized tools or equipment for installation?

- Yes, a waterproofing membrane typically requires specialized tools and equipment for installation. These may include items such as a trowel, roller, brush, or sprayer for application, as well as a heat gun or torch for properly sealing the seams. Additionally, some membranes may require specific adhesives or primers for proper attachment. It is important to consult the manufacturer's guidelines and instructions for the specific membrane being used to ensure proper installation.

- Q: Are there any specific tools or equipment required for installing a waterproofing membrane?

- Yes, there are specific tools and equipment required for installing a waterproofing membrane. Some of the essential tools and equipment include: 1. Protective gear: This includes gloves, goggles, and a face mask to protect yourself from any harmful chemicals or fumes. 2. Cleaning equipment: Before installing the membrane, the surface needs to be clean and free from any dust, debris, or loose particles. Therefore, you may need a broom, vacuum cleaner, or pressure washer to clean the area properly. 3. Waterproofing membrane: The specific type of membrane will depend on the project requirements, but it is essential to have the appropriate membrane material and enough coverage to ensure a proper seal. 4. Primer: In some cases, a primer may be needed to enhance adhesion between the surface and the membrane. The primer type will depend on the surface material and the membrane being used. 5. Application tools: These tools are used to apply the membrane onto the surface. Common tools include brushes, rollers, or sprayers. The choice will depend on the type of membrane and the size of the project. 6. Seam tape: If the waterproofing membrane requires seams, a seam tape will be needed to ensure a watertight seal at the joints. The tape should be compatible with the membrane material. 7. Adhesive or adhesive tape: Some waterproofing membranes require an adhesive to bond them to the surface. Alternatively, adhesive tape can be used for self-adhesive membranes. 8. Cutting tools: Depending on the shape and size of the area to be waterproofed, you may need cutting tools such as utility knives or scissors to trim the membrane to the desired size and shape. 9. Caulking gun: A caulking gun is necessary for applying sealant or caulk to fill any gaps or cracks in the surface before installing the membrane. 10. Drying equipment: After the membrane is installed, it may require a certain amount of time to dry or cure. Fans or dehumidifiers may be needed to accelerate the drying process, depending on the specific membrane and environmental conditions. It is important to consult the manufacturer's guidelines or seek professional advice to ensure you have all the necessary tools and equipment for a successful installation of the waterproofing membrane.

- Q: Can a waterproofing membrane be used on both interior and exterior surfaces?

- Yes, a waterproofing membrane can be used on both interior and exterior surfaces. Waterproofing membranes are designed to protect surfaces from water penetration and damage. They are typically made of materials such as rubber, asphalt, or thermoplastic, which provide a barrier against moisture. Whether it is applied on interior walls, floors, or exterior foundations, roofs, or balconies, a waterproofing membrane can effectively prevent water from seeping through and causing potential issues like leaks, mold, or structural damage. It is important to consider the specific requirements of each surface and choose a waterproofing membrane that is suitable for the intended application.

- Q: Can a waterproofing membrane be used for fire pit areas?

- No, a waterproofing membrane should not be used for fire pit areas. While waterproofing membranes are designed to prevent water penetration, they are not designed to withstand the high temperatures and potential fire hazards associated with fire pits. Fire pit areas require specific fire-resistant materials that can withstand the heat generated by the fire and prevent any potential fire accidents. It is important to use appropriate materials that are specifically designed for fire pit areas to ensure safety and prevent any potential damage.

- Q: Is a waterproofing membrane suitable for both residential and commercial applications?

- Yes, a waterproofing membrane is suitable for both residential and commercial applications. A waterproofing membrane is a versatile material that can be used in various settings to protect buildings and structures from water damage. Whether it is a residential home or a commercial building, a waterproofing membrane can be applied to foundations, roofs, walls, and other areas that are susceptible to water infiltration. It provides a protective barrier that prevents water from seeping into the structure and causing damage such as leaks, mold, and deterioration. Additionally, a waterproofing membrane can be customized to meet the specific needs and requirements of both residential and commercial applications, making it a suitable choice for any type of building.

- Q: Can waterproofing membranes be used on wood surfaces?

- Yes, waterproofing membranes can be used on wood surfaces. Waterproofing membranes are versatile and can be applied to various materials, including wood. They provide a protective barrier that prevents water from penetrating the wood, helping to prolong its lifespan and prevent damage caused by moisture.

- Q: Can a waterproofing membrane be used for a water tank?

- Yes, a waterproofing membrane can be used for a water tank. Waterproofing membranes are designed to create a barrier against water penetration, making them suitable for use in water tanks to prevent leakage and ensure the integrity of the tank.

- Q: Can waterproofing membranes be used on terraces?

- Yes, waterproofing membranes can definitely be used on terraces. In fact, using waterproofing membranes on terraces is highly recommended to protect the structural integrity of the terrace and prevent water damage. Waterproofing membranes act as a barrier, preventing water from seeping into the terrace and causing leaks or cracks. They are commonly used on flat terraces, rooftop terraces, and balconies to ensure that water does not penetrate the surface and cause damage to the underlying structure. Waterproofing membranes are available in various types, such as liquid-applied membranes, sheet membranes, and self-adhesive membranes, providing different options to suit the specific needs and requirements of the terrace. By applying a waterproofing membrane, the terrace can be protected from moisture, UV rays, and other environmental factors, extending its lifespan and ensuring a durable and long-lasting surface.

- Q: Can a waterproofing membrane be used on insulation surfaces?

- Yes, a waterproofing membrane can be used on insulation surfaces. In fact, it is often recommended to install a waterproofing membrane over insulation to provide an additional layer of protection against water infiltration. This is especially important in areas where moisture is a concern, such as basements, roofs, or exterior walls. The waterproofing membrane acts as a barrier, preventing water from seeping into the insulation and causing damage. It also helps to maintain the integrity and effectiveness of the insulation by keeping it dry. Additionally, some waterproofing membranes have the added benefit of improving the energy efficiency of the insulation by reducing air leakage and heat transfer. Overall, using a waterproofing membrane on insulation surfaces is a smart and practical solution to protect your building or home from water damage.

1. Manufacturer Overview

| Location | Shanghai, China |

| Year Established | 1991 |

| Annual Output Value | >RMB 150 millions |

| Main Markets | China; Southeast Asia; |

| Company Certifications | ISO9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai port |

| Export Percentage | >50% |

| No.of Employees in Trade Department | 10-15 people |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | >150000 Square metres |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Negotiated |

Send your message to us

SBS Modified Bitumen Waterproofing Membrane

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 M2 m²

- Supply Capability:

- ONE WEEK PER CONTAINE m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords