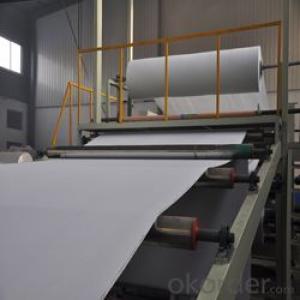

PVC waterproof membrane Reinforced

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC (polyvinyl chloride) roof membrane

is an excellent high quality polymer waterproof sheet, made of PVC resin by adding plasticizer,

anti-UV agent, anti aging agent, and stabilizer and other processing aids through extrusion

and molding.As the highly recommended product by the Ministry of Construction, it is featured by high tensile

strength, great elongation, good stability, small shrinkage, low temperature performances, good resistance to

weathering and root penetration, and long service life.

Physical Property:

1.Good combination of high elasticity and tensile strength.

2.Fine resistance to static electricity.

3.Excellent resistance to ageing / weathering.

4.Durable,the effective age can be more than 20 years used on exposed surfaces,used on non-exposed surfaces,it can reach 50 years.

5.Fine flexibility at low temperature,adaptable to cold conditions.

6.Root-resistance,can be used on the planting roofs.

7.Fine puncture resistance, joint peel strength and joint shear strength.

8.Fine UV-resistance,no pollution to environment.

9.Easily welding,installing,secure.

10.Easy treatments to the delicate parts of corners and edges.

11.Convenient maintenance with low cost.

Polyvinyl Chloride (PVC) membrane with fiber reinforced layer

on the back is widely used in the roofs of civil buildings,

tunnels, channels, subways, highways, planting roofs, the roofs of steel

frame structure buildings, and etc.

- Q: Can a waterproofing membrane be used for podium decks or plaza areas?

- Podium decks or plaza areas can benefit from the application of a waterproofing membrane. It is highly recommended to utilize this protective layer in order to safeguard the underlying structure from water-related harm. Given their exposure to the elements, podium decks and plaza areas are susceptible to water infiltration. By implementing a waterproofing membrane, water seepage into the lower layers can be effectively prevented, thus ensuring the long-lasting durability and structural integrity of the deck or plaza. Furthermore, this waterproofing membrane is also capable of shielding spaces beneath the deck or plaza, such as basements or parking garages, from potential water damage. Therefore, it is crucial to select a top-notch waterproofing membrane specifically designed for outdoor purposes, and to carefully adhere to the manufacturer's instructions regarding proper installation and maintenance.

- Q: Can a waterproofing membrane be installed on a concrete foundation?

- Installing a waterproofing membrane on a concrete foundation is indeed a common practice. This is done to prevent water infiltration and safeguard the structure from moisture-related harm. Typically, the membrane is applied to the exterior surface of the foundation walls, serving as a barrier against water and moisture. The type of membrane used can vary, ranging from liquid-applied to sheet membrane or a combination of both, depending on the project's specific requirements. Its purpose is to act as a protective layer, preventing water from penetrating the foundation and causing issues like dampness, mold growth, and structural decay. By incorporating a waterproofing membrane into a concrete foundation, homeowners and builders can guarantee the structure's long-term durability and integrity.

- Q: Can a waterproofing membrane be used for underground communication vaults?

- Yes, a waterproofing membrane can be used for underground communication vaults. Underground communication vaults are typically made of concrete or other materials that are susceptible to water infiltration. To prevent water damage and ensure the longevity of the vault, a waterproofing membrane can be applied to the exterior surface of the vault. This membrane acts as a barrier, preventing water from entering the vault and causing damage to the equipment or infrastructure inside. Additionally, the waterproofing membrane can also protect against other potential threats such as moisture, chemicals, and soil gases. It is important to choose a high-quality waterproofing membrane that is specifically designed for underground structures to ensure its effectiveness and long-term durability.

- Q: Can a waterproofing membrane be used on adobe block surfaces?

- Yes, a waterproofing membrane can be used on adobe block surfaces. Adobe blocks are made from a mixture of clay, sand, and straw, which can be susceptible to water damage. Applying a waterproofing membrane can help prevent water penetration and protect the adobe blocks from moisture-related issues such as cracking, erosion, or mold growth. It is important to ensure that the waterproofing membrane is compatible with adobe surfaces and follows the manufacturer's guidelines for application. Additionally, proper surface preparation and repair of any existing damage is crucial before applying the membrane to ensure its effectiveness.

- Q: Can a waterproofing membrane be applied in cold weather?

- Yes, a waterproofing membrane can be applied in cold weather. However, there are certain considerations that need to be taken into account. It is important to use a membrane that is specifically designed for cold weather applications as some membranes may not perform optimally in low temperatures. Cold weather can affect the curing process of the membrane, so it is crucial to follow the manufacturer's guidelines regarding temperature limitations and application techniques. The surface to be waterproofed should also be clean and dry before applying the membrane, as moisture or ice can interfere with adhesion. In cold weather, it may take longer for the membrane to fully cure and achieve its maximum performance. Therefore, it is advisable to allow sufficient time for the membrane to dry and cure before exposing it to water or other stressors. It is also important to note that extreme cold temperatures can negatively impact the installation process and the overall effectiveness of the waterproofing system. Therefore, it is recommended to consult with a professional waterproofing contractor who has experience working in cold weather conditions to ensure the best results.

- Q: Can a waterproofing membrane be used for a hospital?

- A hospital can indeed utilize a waterproofing membrane. In construction projects, waterproofing membranes are frequently employed to safeguard the integrity of building materials by preventing moisture infiltration. In a hospital environment, where hygiene and infection control hold paramount importance, maintaining a dry and clean surrounding is crucial to hinder the growth of mold, mildew, and bacteria. A waterproofing membrane can serve as a barrier against water and moisture, thus averting any potential harm to the structure and ensuring a secure and healthy environment for patients, staff, and visitors. Moreover, specific areas of a hospital, such as operating rooms or laboratories, where the likelihood of spills or water exposure is higher, can also benefit from the use of waterproofing membranes. In summary, the incorporation of a waterproofing membrane in a hospital contributes to upholding a high standard of cleanliness, safety, and durability within the facility.

- Q: Can a waterproofing membrane be used in elevator pits?

- Yes, a waterproofing membrane can be used in elevator pits. Elevator pits are vulnerable to water damage and moisture accumulation, so applying a waterproofing membrane can help prevent water intrusion and protect the elevator components from potential damage.

- Q: Is a waterproofing membrane resistant to hydrocarbons or oils?

- Yes, a waterproofing membrane is typically resistant to hydrocarbons or oils.

- Q: Can waterproofing membranes be used on bridge decks?

- Bridge decks can benefit greatly from the application of waterproofing membranes. Due to the constant exposure to harsh weather conditions like rain, snow, and freeze-thaw cycles, the concrete and steel reinforcement of bridge decks can deteriorate. Waterproofing membranes are specifically designed to counter water infiltration and safeguard the bridge deck against damage caused by moisture. Typically composed of flexible materials like bitumen, PVC, or EPDM rubber, these membranes are directly applied to the surface of the bridge deck. Acting as a barrier, they prevent water from seeping into the concrete and causing corrosion of the reinforcement. They also help minimize crack formation and extend the lifespan of the bridge deck. Furthermore, the effectiveness and durability of waterproofing membranes can be enhanced by combining them with other protective coatings or systems. All in all, the utilization of waterproofing membranes on bridge decks is a widely employed and successful approach to ensure the long-term integrity and functionality of the structure.

- Q: Are waterproofing membranes flexible?

- Waterproofing membranes, generally, exhibit flexibility. Their purpose is to be adaptable, enabling them to mold and adjust to the contours and shifts of the surfaces they are applied on. This adaptability effectively seals off any openings, fissures, or connections, effectively barring water infiltration into the foundation. Additionally, the elasticity of waterproofing membranes empowers them to endure the expansion and contraction caused by temperature fluctuations or structural shifts. In conclusion, the flexibility of waterproofing membranes is an essential attribute that guarantees their resilience and efficacy in safeguarding structures against water-related harm.

Send your message to us

PVC waterproof membrane Reinforced

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords