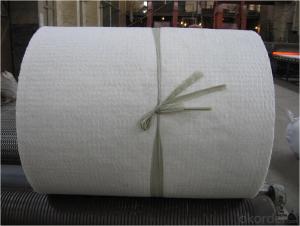

Waterproof Thermal Blanket

Waterproof Thermal Blanket Related Searches

Waterproof Material Waterproof Shade Cloth Waterproof Sealer Waterproof Seal Waterproofing Wet Areas Waterproof Paper Waterproof Paint Waterproofing Felt Roof Residential Waterproofing Waterproof Particle Board Waterproof Double Sided Tape Waterproof Resin Waterproof Cement Board Shower Furnace Insulation Blanket Waterproofing Homes Spray Waterproof Sealant Commercial Waterproofing Blanket Insulation For Steel Buildings Bentonite Waterproofing Membrane Waterproof Concrete Blocks Waterproof Membrane For Decks Backer Board Waterproof Waterproofing Concrete Block Walls Paintable Waterproof Membrane Roofing Paper Waterproof Material Waterproofing Spray Waterproof Spray Waterproofing Inspection Waterproof Admixture Concrete Waterproof Mdf PanelsWaterproof Thermal Blanket Supplier & Manufacturer from China

Waterproof Thermal Blankets are specially designed products that offer insulation and protection from the elements, making them ideal for various outdoor activities and emergency situations. These blankets are crafted with a waterproof exterior and a thermal interior, ensuring warmth and dryness in challenging weather conditions.The application and usage scenarios of Waterproof Thermal Blankets are vast, ranging from camping and hiking to emergency preparedness and disaster relief. They are perfect for providing warmth during unexpected weather changes, offering a protective layer in case of sudden rain or snow, and serving as a life-saving tool in survival situations. These blankets can also be used in construction sites, military operations, and other outdoor events where protection from the elements is crucial.

Okorder.com is a reputable wholesale supplier of Waterproof Thermal Blankets, boasting a large inventory that caters to the diverse needs of customers worldwide. With a commitment to quality and customer satisfaction, Okorder.com ensures that each Waterproof Thermal Blanket is manufactured to the highest standards, providing reliable insulation and protection for all users.

Hot Products