Thermal Shock Resilient Ceramic Fiber Blanket

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceramic Fibre Blanket Sheet Resilient to Thermal Shock

Structure of Ceramic Fibre Blanket Sheet Description

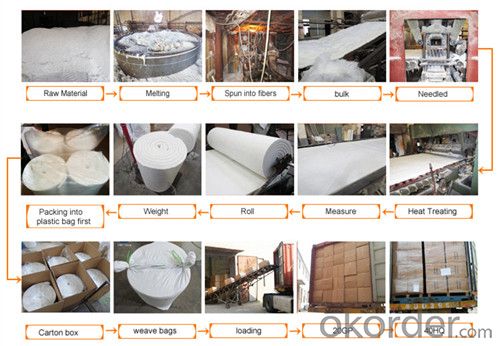

Ceramic Fibre is made from high quality clay, high

purity alumina and silica oxides by spun or blown process.

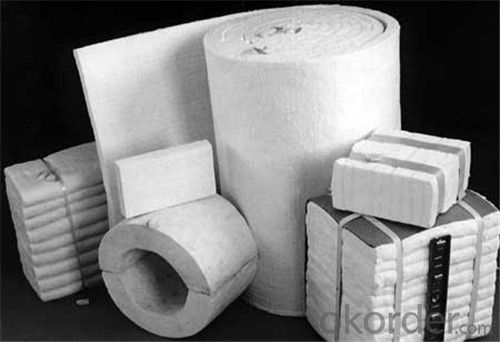

Ceramic Fibre Blanket Sheet has a range of products:ordinary type,standard form,high-purity type, high-alumina type and containing zirconium type.Different types of products used different materials. performance of Ceramic Fibre Blanket Sheet also has difference,and they are suitable for different workong temperatures.

Ceramic Fibre can be used after optional cutting .When Ceramic Fibre Blanket Sheet storage should be paid attention to moistureproof.The high-alumina type and containing zirconium type products can be directly used as furnace lining .And using high-temperature refractory adhesive when stick.

Main Features of the Ceramic Fibre Blanket Sheet

◆Low thermal conductivity

◆High tensile strength

◆Resilient to thermal shock

◆Corrosion resistance

Advandage for Ceramic Fibre Blanket Sheet

◆High-purity type

◆High-temperature refractory

◆Al Content (%): 32-55

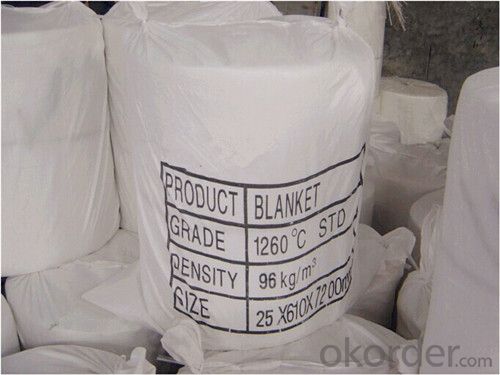

◆Type: 1260℃ STD/HP, 1350℃ HA, 1430℃ HZ

◆Density: 64-160kg/m3

◆Size: 12.5×610×14400mm, 25×610×7200mm, 50×610×3600mm

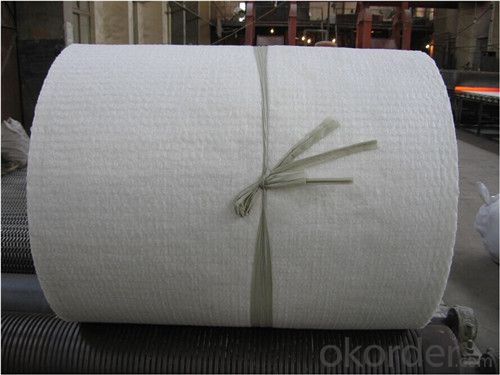

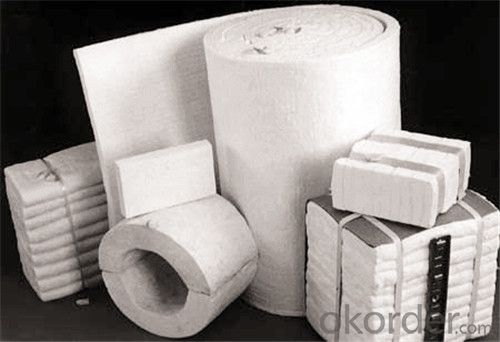

Ceramic Fibre Blanket Sheet Images

◆Packaging

◆Product Process

Ceramic Fibre Blanket Sheet Specification

Type | Ordinary | Standard | High Purity | High Aluminium | Zirconia | |

Classification temperature (°C) | 1100 | 1260 | 1260 | 1360 | 1430 | |

Working Temperature (°C) | < 1000 | 1050 | 1100 | 1200 | 1350 | |

Color | white | spotlessly white | spotlessly white | spotlessly white | spotlessly white | |

Density (kg/m3) | 96 | 96 | 96 | 128 | 128 | |

Shrinkage on heating (%) (24 hours,density as 128/m3) | -4 | -3 | -3 | -3 | -3 | |

Thermal conductivity by different temperature (w/m.k) (density as 128kg/m3) | 0.09(400°C) | 0.09(400°C) | 0.09(400°C) 0.16(800°C) | 0.12(600°C) | 0.16(800°C) | |

Tensile strength (MPa) | 0.04 | 0.04 | 0.04 | 0.04 | 0.04 | |

Chemical composition (%) | AL2O3 | 44 | 46 | 47-49 | 52-55 | 39-40 |

AL2O3+SIO2 | 96 | 97 | 99 | 99 | - | |

AL2O3+SIO2+ZrO2 | - | - | - | - | 99 | |

FAQ of Ceramic Fibre Blanket Sheet

◆Can we accept OEM for Ceramic Fibre Blanket Sheet?

YES! We can according your demand to produce.

◆Can we accept the detective of the third-party verification company ?

YES! We can accept the detective from any third-party verification company including the SGS, BV and so on.

If you have any enquiry,please don't hesitate to contact us, we will provide our best products and services for you!!

- Q: When we talk about textile yarns( cotton), what is meant by Open End yarn ( OE) and Ring Spun Yarn ( RS) .?Differentiate between the two types of yarnThanks.Anjan.

- Chewing gum must be considered food because it contains calories A paper wrapper is used on the outside of aluminum and paper because it is used to keep the item fresh I don't know the rest

- Q: how do you dye yarn?.?

- If you are using acrylic yarn, you can't dye itIn fact, most of the synthetics are going to be really hard to dye at allIf it's animal fibre, you can use any acid dyeIf it's plant fibre, you are going to use a fibre reactive dyeThese are not the same, and they don't work on the other fibreIf you use union dyes, you can dye either one of them, but you get some waste of dyes that way tooUnless you know what material your yarn is made from, there is nothing more we can tell youThe directions for each type of dye is available on several web sites.

- Q: Okay so I can't sew, crochet, or anything like thatMaybe some simple sewing but thats itSome materials I have are: Markers, pencils, pens, paper (all sizes and colors), stickers, cardboard, sparkles, beads, string and yarn, glue, and some fabricThanks in advanceBy the way, more than one idea would be appreciated.

- I think it's a very good idea

- Q: what are the examples of vegetables high in dietary fibre? is parsley high in dietary fibre?

- NOOOOOO.wax paper should not be used in the oven, it will smokeUse parchment paper instead (found in the same aisle as tin foil and wax paper)Parchment is wonderful for cooking fish and chicken.

- Q: what type of stitch is this?

- I had a tree trimming company trim 3 treesThey looked at the trees, offered recommendations on trimming and shaping the treesI hired them and now the trees have a great shape and look fine.

- Q: I've been sleeping under the comforter all my life.and now I'm just realizing that people sleep under the sheets AND comforter.what the heck? isn't that too hot? And then I found out also just recently that people drink tap water like it's normal? I've been raised on distilled water from the gallons my whole entire life! Where have I been?

- Do you drink a lot of coffee? You said you often get it when you're nervous or excited, which is also a side effect of caffeineThe only time I get diarrhea is when I drink too much coffee and not enough food.

- Q: carpet fiber differecnes?

- There are more than 7 different fibers used in carpetDo you want to know about all 7? If so what type of carpet do you want, it makes a big differenceAt the present time the best all around fiber is TriextaIt is a some what new yarn from MohawkIt's main ingredient comes from cornFrom a farmers field, not a oil rich countryLet me know what info you want, what type of carpet and I will post more info.

- Q: i've had a cold for a few daysi've been coughing out yellow/greenish mucus and i woke up with a huge headache, and because of that i checked my mouth temperature and it was 93 degrees on all of my thermometers ( i have 4 digital ones different brands)Right now i'm wrapped up in blankets on a futon, is there anything else i can do?

- Your temperature is almost critical! You've got severe hypothermiaCall an ambulance!

- Q: There used to be indoor/outdoor carpet in my basement, so I ripped it up to find old parquet tiles and a tar-like adhesiveNeedless to say, it was quite horribleI was able to remove all the tars and some of the adhesiveI ended up putting carpet tiles over the remainder of the floor and now the basement is damp (starting to smell moldy and musty)Any ideas on how to re-do the flooring (inexpensive and quickly) so that there are no more water issues?

- Best Constipation Cures

Send your message to us

Thermal Shock Resilient Ceramic Fiber Blanket

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords