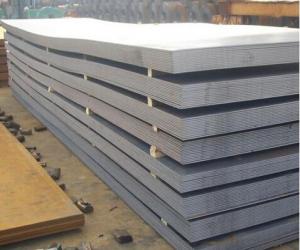

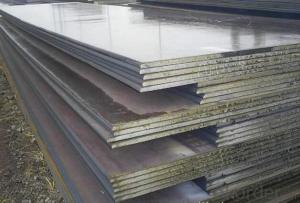

Hot Rolled Steel Sheet

Hot Rolled Steel Sheet Related Searches

Pu12 Sheet PileHot Searches

Used Metal Folding Chairs For Sale Large Metal Containers For Sale Metal Shop Cabinets For Sale Metal Shipping Crates For Sale High Mast Light Price List Solar High Mast Light Specification Galvanized Steel Scrap Price Fiber Sheet Price In India Types Of Stainless Steel Grades High Mast Light Specification Stainless Steel Sheet Near Me Stainless Steel Type Type Stainless Steel Galvanized Steel Prices Stainless Steel Wholesale Stainless Steel Tubing Supplier Stainless Steel Supply Near Me Stainless Steel Supply Stainless Steel Sheets Near Me Scrap Stainless Steel PricesHot Rolled Steel Sheet Supplier & Manufacturer from China

Okorder.com is a professional Hot Rolled Steel Sheet supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Hot Rolled Steel Sheet firm in China.Hot Products

FAQ

- Yes, steel sheets are highly resistant to warping under heat. Steel has a high melting point and excellent thermal conductivity, which helps it maintain its structural integrity even at high temperatures. This makes steel sheets a suitable choice for applications where heat resistance is crucial, such as in construction, automotive, and industrial manufacturing.

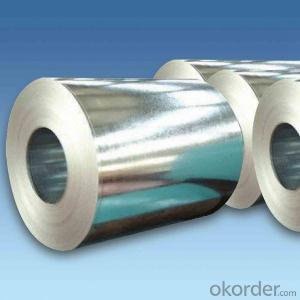

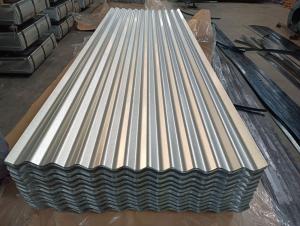

- The different surface textures for galvanized steel sheets include smooth, matte, and patterned textures.

- The weight of a typical steel sheet can vary depending on its dimensions and thickness. However, on average, a standard steel sheet can weigh anywhere from 15 to 30 pounds per square foot.

- Who knows the wire width of the steel mesh?

- Steel wire should be called stem stem.

- Yes, steel sheets can be used in telecommunications applications. Steel provides strength and durability, making it suitable for housing and protecting telecommunications equipment such as cabinets, racks, and enclosures. It also offers excellent electromagnetic shielding properties, which help prevent interference and maintain signal integrity.

- There are several types of surface finishes available for steel sheets, each serving different purposes and providing distinct aesthetics. Some of the most common types include: 1. Hot rolled: This finish is achieved by heating the steel above its recrystallization temperature and then rolling it, resulting in a rough texture. It is commonly used for structural applications where aesthetics are not a primary concern. 2. Cold rolled: In contrast to hot rolled, cold rolled steel sheets are processed at room temperature, resulting in a smoother and more refined finish. This finish is often used for applications that require a higher level of precision or a more visually appealing surface. 3. Galvanized: Galvanization involves coating steel sheets with a layer of zinc, providing excellent corrosion resistance. This finish is commonly used in outdoor applications or environments with high levels of moisture. 4. Electro-galvanized: Similar to galvanized finish, electro-galvanized steel sheets are coated with a layer of zinc. However, this process involves the use of an electrical current to deposit the zinc, resulting in a thinner and more uniform coating. 5. Stainless steel: This finish is achieved by adding chromium to steel sheets, creating a protective layer that prevents corrosion and staining. Stainless steel is known for its high strength and resistance to a wide range of chemicals, making it suitable for various applications, including kitchen appliances and medical equipment. 6. Satin: This finish is characterized by a smooth and brushed appearance, achieved by using abrasive materials on the steel surface. Satin finish provides a low-reflective surface with a subtle sheen, making it commonly used for architectural and decorative purposes. 7. Mirror: As the name suggests, mirror finish steel sheets have a highly reflective surface that resembles a mirror. This finish is achieved by polishing the steel using progressively finer abrasives until a mirror-like surface is obtained. Mirror finish is often used in decorative applications, such as furniture, automotive trim, and decorative panels. 8. Painted: Steel sheets can also be coated with paint to enhance their appearance and provide additional protection against corrosion. This finish offers endless color options and customization possibilities, making it suitable for a wide range of applications. These are just a few examples of the various surface finishes available for steel sheets. The choice of finish will depend on the specific requirements of the application, including aesthetics, corrosion resistance, and functionality.

- Steel sheets are typically protected from damage during handling and transportation through various methods such as applying protective coatings, using packaging materials like plastic wrapping or wooden crates, utilizing foam or rubber padding, and using proper lifting and securing techniques to prevent any shifting or impact.