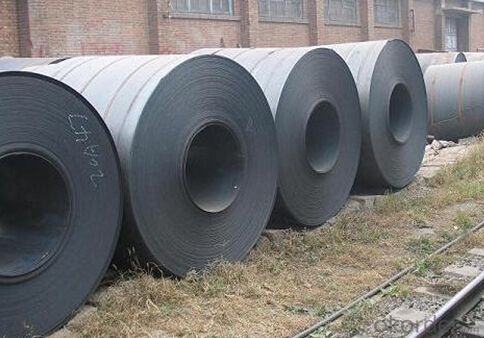

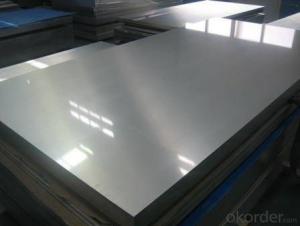

2mm_2.2mm Hot Rolled Steel Coil HR coil/sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

2mm_2.2mm Hot Rolled Steel Coil HR coil/sheet

Quick Details

Name | Hot Rolled Steel Coil |

Standard | GB/ASTM/SAE/AISI/DIN/JIS/EN/BS |

Surface Treatment: | Black/Peeling/Polished/Machined |

Delivery Condition: | Hot Rolled or Forged/Peeled or Black Surface |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

Specification

Standard | Grade | General Size | Delivery Condition |

ASTM A36 | A36/A36-B | 5-20 * 2300-2500 * C | Boron added or Black Condition |

ASTM A283 | A283-B/A283C | 5-20 * 2300-2500 * C | Boron added or Black Condition |

ASTM A572 | A572Gr50-B/A572Gr42-B | 5-20 * 2300-2500 * C | Boron added or Black Condition |

ASTM A515 | A515Gr70 | 5-20 * 2300-2500 * C | Black Condition |

ASTM A516 | A516Gr70 | 5-20 * 2300-2500 * C | Black Condition |

JIS G 3101 | SS400-B | 5-20 * 2300-2500 * C | Boron added or Black Condition |

JIS G3136 | SN400B | 5-20 * 2300-2500 * C | Boron added or Black Condition |

EN10025-2:2004 | S235JR-S355K2+N | 5-20 * 2300-2500 * C | Boron added or Black Condition |

EN10025-5:2004 | S355J2W/S355K2W | 5-20 * 2300-2500 * C | Black Condition |

Company Information

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service | l CNBM provides the services and support you need for every step of our cooperation. We’re the business partners you can trust; you can relax and get on with doing business. |

l For any problem, please kindly contact us at any your convenient time, we’ll reply you in our first priority within 24 hours | |

Advantages | Industry experience over 20 years. |

Shipment of goods -More than 70 countries worldwide. | |

The most convenient transport and prompt delivery. | |

Competitive price with best service. | |

High technical production line with top quality products. | |

High reputation based on best quality products. |

Product Show

FAQ

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. |

Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. | |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust |

Where are your Market? | Covering more than 160 countries in the world |

- Q: What are the requirements for special steel used in mining equipment manufacturing?

- The requirements for special steel used in mining equipment manufacturing typically include high strength and toughness to withstand the harsh operating conditions, excellent wear resistance to endure abrasive materials, good corrosion resistance to resist chemical exposure, and high fatigue strength to withstand repeated loading. Additionally, the steel should have good weldability and machinability to facilitate fabrication processes.

- Q: What are the effects of different heat treatment processes on special steel?

- Different heat treatment processes have varying effects on special steel. Annealing, for example, helps to soften the steel and increase its ductility, making it easier to shape and work with. Hardening processes, such as quenching and tempering, increase the steel's hardness and strength, making it suitable for applications that require toughness and resistance to wear. Tempering, on the other hand, reduces the hardness of the steel while increasing its toughness. Additionally, heat treatment processes can also influence the steel's internal structure, such as the size and distribution of grains, which in turn affects its mechanical properties. Overall, the choice of heat treatment process can significantly impact the final characteristics of special steel, allowing for customization to meet specific performance requirements.

- Q: What are the heat treatment processes used for special steel?

- There are several heat treatment processes used for special steel, including annealing, normalizing, quenching, tempering, and precipitation hardening. These processes are designed to enhance the strength, hardness, toughness, and ductility of the steel, depending on the specific requirements of the application.

- Q: What are the common applications of special steel in the manufacturing industry?

- Special steel, known as alloy steel as well, has unique properties and superior performance, making it widely used in the manufacturing industry for various applications. Different sectors benefit from special steel in the following ways: 1. Automotive Industry: Components like engine parts, gears, axles, and crankshafts heavily rely on special steel due to its high strength, durability, and resistance to wear and corrosion. Its exceptional performance in critical automotive applications makes it the preferred choice. 2. Aerospace Industry: In the aerospace sector, special steel is vital for manufacturing aircraft components such as landing gear, turbine blades, and structural parts. Its high tensile strength, lightweight nature, and ability to withstand extreme temperatures ensure the safety and efficiency of aircraft operations. 3. Construction Industry: The construction sector extensively uses special steel for manufacturing structural elements like beams, columns, and reinforcement bars. Its superior strength, ductility, and resistance to external forces guarantee the structural integrity and safety of buildings, bridges, and other infrastructure projects. 4. Oil and Gas Industry: The oil and gas industry relies heavily on special steel for manufacturing pipelines, drill bits, valves, and other equipment. Its high resistance to corrosion, pressure, and extreme temperatures make it suitable for handling the harsh operating conditions encountered in oil and gas exploration, extraction, and transportation. 5. Tool and Die Making: Special steel is commonly employed in tool and die making due to its excellent hardness, toughness, and wear resistance. Various industries, including automotive, aerospace, and consumer goods manufacturing, utilize special steel for manufacturing cutting tools, molds, dies, and punches. 6. Medical Industry: The medical industry utilizes special steel for manufacturing surgical instruments, implants, and medical devices. Its biocompatibility, corrosion resistance, and sterilizability ensure the safety and effectiveness of medical tools and implants. These examples represent only a fraction of the applications of special steel in the manufacturing industry. Its versatility, reliability, and performance contribute to the advancement and growth of various manufacturing processes in numerous sectors.

- Q: What are the requirements for special steel used in corrosive environments?

- The requirements for special steel used in corrosive environments include high resistance to corrosion, especially against specific corrosive agents such as acids, alkalis, or saline solutions. The steel should possess a strong passive film formation ability, preventing further corrosion. It should also have good mechanical properties, including high strength and toughness, to withstand the harsh conditions. Additionally, the steel must possess good welding and fabrication characteristics, as well as be cost-effective and readily available.

- Q: What is the impact of carburizing on the properties of special steel?

- Carburizing, also known as case hardening, is a heat treatment process that involves introducing carbon into the surface layer of special steel. This process has a significant impact on the properties of the steel, enhancing its hardness, wear resistance, and strength. One of the main effects of carburizing is the formation of a hard outer layer, known as the case, which is rich in carbon. The diffusion of carbon atoms into the steel matrix during carburizing increases the carbon content at the surface, resulting in a higher hardness compared to the core. This hardened case provides excellent resistance against wear, abrasion, and surface fatigue, making it well-suited for applications that require high durability, such as gears, camshafts, and bearings. Additionally, carburizing enhances the strength of the steel, as the increased carbon content improves the material's ability to form martensite, a hard, crystalline structure. This martensitic transformation further contributes to the hardness and strength of the carburized steel, making it suitable for applications that require high load-bearing capacity, such as shafts and axles. Furthermore, carburizing can improve the fatigue resistance of special steel. The hardened case formed during carburizing helps to distribute stress more evenly across the surface, reducing the likelihood of crack initiation and propagation. This increased resistance to fatigue failure makes carburized steel suitable for components subjected to cyclic loading, such as gears and springs. However, it is important to note that carburizing can also have some drawbacks. The increased carbon content at the surface can lead to reduced ductility and toughness, making the material more prone to brittle fracture. To mitigate this issue, it is common to use a lower carbon content steel for the core, ensuring a balance between hardness and toughness. In conclusion, carburizing has a significant impact on the properties of special steel. It enhances hardness, wear resistance, and strength, making it suitable for applications that require durability, high load-bearing capacity, and fatigue resistance. However, the process should be carefully controlled to maintain a balance between hardness and toughness, ensuring the material's overall performance and reliability.

- Q: How does special steel contribute to the chemical resistance of products?

- Special steel, also known as stainless steel, contributes significantly to the chemical resistance of products due to its unique composition and properties. These steels contain a high percentage of chromium, which forms a thin, passive oxide layer on the surface of the steel. This oxide layer acts as a protective barrier, preventing corrosive substances from coming into direct contact with the steel and causing chemical reactions. The chromium in special steel forms a stable oxide layer that is highly resistant to corrosion, even in harsh chemical environments. This oxide layer is self-repairing, meaning that if it is damaged or scratched, it will quickly reform and continue to protect the steel. Additionally, the presence of other alloying elements such as nickel and molybdenum further enhances the chemical resistance of special steel. The chemical resistance of special steel extends to a wide range of corrosive substances, including acids, alkalis, and salts. This makes it highly suitable for applications in various industries such as chemical processing, pharmaceuticals, food processing, and marine environments. By using special steel in the manufacturing of products, the risk of chemical degradation and corrosion is significantly reduced. This leads to increased product lifespan, improved performance, and reduced maintenance costs. Furthermore, it ensures that the integrity and safety of the products are maintained, as chemical resistance is crucial in preventing leaks, contamination, and structural failures. In summary, special steel contributes to the chemical resistance of products by forming a protective oxide layer on its surface, which shields it from corrosive substances. Its unique composition and properties make it highly resistant to chemical degradation, ensuring the longevity and reliability of products in various industrial applications.

- Q: What are the cutting tools used for machining special steel?

- The cutting tools commonly used for machining special steel include carbide inserts, high-speed steel (HSS) drills, end mills, and broaches. These tools are specifically designed to withstand the high temperatures and hardness of special steels, ensuring precise and efficient cutting operations.

- Q: How does special steel perform in terms of magnetic properties?

- Special steel can exhibit a wide range of magnetic properties depending on its composition and processing. Some special steels, such as stainless steel, are generally non-magnetic or have very low magnetic permeability. However, certain types of special steel, such as tool steel or high-speed steel, can be engineered to possess magnetic properties suitable for specific applications, such as magnetic tools or electrical transformers. Overall, the magnetic properties of special steel can be tailored to meet the desired requirements for different applications.

- Q: How does special steel contribute to the shipbuilding industry?

- Special steel contributes to the shipbuilding industry in several ways. Firstly, special steel offers enhanced strength and durability, making it an ideal material for constructing various components of ships. This includes the hull, decks, bulkheads, and other structural elements that need to withstand the harsh marine environment and heavy loads. Special steel also provides excellent resistance to corrosion and abrasion, which is crucial for ships that are constantly exposed to saltwater and other corrosive agents. This ensures that the ship remains in good condition for a longer lifespan, reducing maintenance costs and increasing operational efficiency. Moreover, special steel offers superior weldability and formability, allowing shipbuilders to create complex shapes and structures with ease. This flexibility in design enables the construction of innovative and efficient ship designs, such as large container vessels, offshore oil rigs, and naval warships. In addition, special steel is often used for manufacturing critical components like propeller shafts, rudders, and engine parts. These components require high strength, toughness, and resistance to fatigue, as they are subjected to extreme forces and vibrations during operation. Special steel's unique properties ensure the reliability and performance of these crucial ship parts. Furthermore, special steel contributes to the shipbuilding industry by enabling the construction of lightweight ships without compromising strength and safety. This helps reduce fuel consumption, leading to improved energy efficiency and lower greenhouse gas emissions. As environmental regulations become increasingly stringent, special steel plays a vital role in making ships more sustainable and eco-friendly. Overall, special steel is an essential material in the shipbuilding industry due to its exceptional strength, durability, corrosion resistance, weldability, formability, and lightweight properties. Its use not only ensures the safety and longevity of ships but also facilitates the development of advanced ship designs and contributes to the industry's overall sustainability.

Send your message to us

2mm_2.2mm Hot Rolled Steel Coil HR coil/sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords