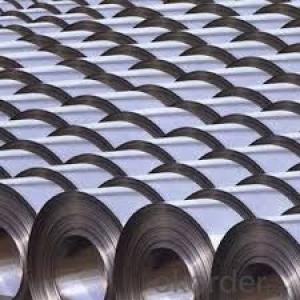

Hot rolled steel coils/Sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product: | Hot Rolled Steel Coils/Sheets |

Material: | Q195,Q235,A36,SS400,S235JR,Q345,ST37-2, CCSB etc |

Standard : | JIS G3002 GB/T251B |

Technique: | hot rolled |

Thickness | 1.2mm to 200mm |

Tolerance of thickness: | :+/-0.03mm |

Width: | 750mm-2000mm |

Tolerance of width: | :+/-5.00mm (aiming to +/-2.00mm) |

Normal width: | 914mm, 1000mm, 1200mm, 1219mm, 1250mm,1500mm |

Length: | According to requirement |

Coil ID: | 508mm-610mm |

Coil Weight: | 10-25 Metric Tons |

Surface: | Black, Chromate, fingerprint resistant treatment, slight oiled or non-oiled, dry |

Port of Loading: | Tianjin/Shanghai port |

Packaging Details: | Standard export packing or according to the clients required |

Delivery Time | Within 30 days after received 30% deposit or workable L/C |

Payment Terms: | L/C,T/T |

|

|

- Q: How are steel coils protected against bending and deformation?

- Various measures are implemented to safeguard steel coils from bending and deformation. One prevalent approach entails employing protective packaging materials, such as wooden crates or metal skids. These materials provide stability and support, effectively preventing any bending or deformation during transportation or storage. Additionally, steel coils are frequently tightly secured using steel or plastic bands. This measure serves to maintain their shape and prevent any shifting or movement. These bands are strategically positioned at regular intervals along the length and width of the coils, guaranteeing even pressure distribution and minimizing the risk of bending or deformation. Furthermore, steel coils can be further shielded by placing them on a flat and level surface during storage or transportation. This practice ensures the even distribution of weight, thus reducing the likelihood of bending or deformation due to uneven pressure. In certain instances, steel coils may also be coated with anti-corrosion agents. This protective coating shields against moisture and rust, which can weaken the structural integrity of the coils and lead to bending or deformation over time. In conclusion, the combination of appropriate packaging, secure fastening, and careful handling is paramount in safeguarding steel coils against bending and deformation. This comprehensive approach ensures the maintenance of their structural integrity and quality.

- Q: How are steel coils used in the production of bridges and infrastructure?

- Steel coils are used in the production of bridges and infrastructure as they are rolled into different shapes and sizes to form the structural components. These coils are then used to create beams, girders, and columns, providing strength and support to the structures. The flexibility and durability of steel allow for the construction of bridges and infrastructure that can withstand heavy loads, extreme weather conditions, and long-term use.

- Q: How can I arbitrate quality of steel before purchasing it??

- The quality of the alloy can be very well be judged by its appearance and lustrous surface. The more luster on the surface the more refine will the steel be. To judge its tenacity and endurance, the alloy can be subjected to a series of procedures involving stress and shock. The reaction to these processes can determine whether the steel be fit for the purpose required.

- Q: I expect that I will be questioned about my knowledge in methoding for steel castings, in a interview. I dont know about it. Can someone explain me in simple language and give me some links, like how I can explain methoding for steel castings.....key points...help please...so that i will pass the interview as if I have experience in methoding....thanks

- It is very difficult to define Methoding of Steel castings by one sentence. Actually it encompasses the total casting process. Normally it would mean a) Pattern design i.e. what type of pattern it would be- wooden, metallic, split or full, loose or fitted on a match plate or any other, how will be the parting line. b) Design of the gating system. c) Design of risering i.e. numbers, size and location of risers. d) Design of molding process i.e. sand system to be used, mold box size. But to do justice to the above mentioned activities, you need to consider other parameters of the casting process such as chemical composition, solidification characteristics, pouring temperature, pouring time, knock out time etc. As I said Methoding of Steel castings means designing of the total casting process from inception to final product.

- Q: What are the common coil slitting methods?

- The common coil slitting methods include rotary shear slitting, loop slitting, and single-knife slitting.

- Q: What are the surface treatments for steel coils?

- Steel coils have multiple options for surface treatments, each with a particular purpose and unique advantages. Some popular surface treatments for steel coils are: 1. Hot-dip galvanization: This technique involves submerging the steel coil in molten zinc, resulting in a protective layer of zinc coating on the surface. Galvanization provides outstanding corrosion resistance, making the steel coil suitable for outdoor use in harsh environments. 2. Electro-galvanization: By using an electrolytic process, a thin layer of zinc is deposited onto the steel coil's surface. Electro-galvanization offers good corrosion resistance, although the coating is generally thinner compared to hot-dip galvanization. 3. Pre-painting or pre-coating: Prior to being formed into final products, steel coils can be coated with paints or other coatings. This surface treatment enhances the coil's visual appeal while providing protection against corrosion, weathering, and other environmental factors. 4. Pickling and oiling: This treatment involves immersing the steel coil in an acid solution to remove oxides and scale from the surface. After pickling, the coil is typically coated with oil to prevent rust formation during storage and transportation. 5. Phosphating: Phosphating is a chemical conversion coating process that forms a phosphate layer on the steel coil's surface. This treatment improves the adhesion of subsequent coatings, such as paints or primers, while also offering some corrosion resistance. 6. Organic coatings: Steel coils can be coated with various organic materials, including epoxy, polyester, or polyurethane, to enhance their corrosion resistance and aesthetic appearance. These coatings provide a wide range of colors, textures, and finishes, making them suitable for diverse applications. It is important to consider the intended application, environmental conditions, and desired appearance when choosing a surface treatment for steel coils. Manufacturers and end-users must carefully evaluate these factors to select the most suitable surface treatment for their specific requirements.

- Q: Can steel coils be stored outdoors?

- Yes, steel coils can be stored outdoors, but it is not recommended for long-term storage. Outdoor storage exposes the coils to the elements, which can lead to corrosion and other forms of damage. It is preferable to store steel coils indoors or in covered areas to ensure their longevity and protect them from environmental factors.

- Q: I'm in the process of buying a new car, and wondering if there are more benefits from Aluminum tire rims over Steel. Aluminum wheels cost more, but you'd think that steel would last longer. Are Aluminum wheels just for looks?

- aluminum is lighter , alot of performance cars use them to trim unsprung weight from the wheels ... steel wheels are cheaper but u have to put hub caps on them ... eeeeeuuuuueeewww!!!!!

- Q: How are steel coils used in the manufacturing of automotive fuel tanks?

- Steel coils are used in the manufacturing of automotive fuel tanks as they provide strength, durability, and resistance to corrosion. These coils are formed and welded into shape to create the fuel tank, ensuring it can withstand the pressure and vibrations associated with storing and transporting fuel safely.

- Q: I have steel on my 9.5 ti now.. ive heard about synthetic being stronger but it snaps when it hits something sharp.. opinions people?

- Steel is more dangerous, both in a fatal metal whip way and a metal splinters in my hand way. Steel weighs more. So why would anyone continue to use steel? Cost and care. Care: Steel can sit for years without having to worry about dry rot (as long as it's not out in too horrible of weather conditions). Steel is much more resistant to fraying. You don't have to baby steel so much to keep it in good conditions. Cost: As of right now, steel is less than half the cost of synthetic. A synthetic rope can cost as much as many electric winches which include a steel cable. I find that I don't use my winch nearly enough to warrent the extra care or cost of a synthetic. The weight savings would be nice, but I kind of ruined that a long time ago with the winch bumper, rock sliders, plate steel fenders/flares, belly armor and frame plating.

Send your message to us

Hot rolled steel coils/Sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords