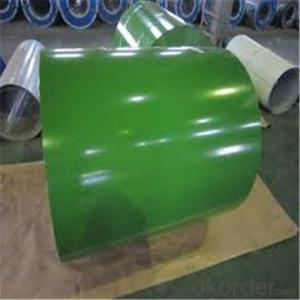

Dried Aluzinc Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- T/T or L/C

- Min Order Qty:

- 25mt m.t.

- Supply Capability:

- 5000mt/per month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information Of Galvalume Steel Coil AZ150

With Cold Rolled Steel as base metal,with the aluzinc coated, finally the plate steel is called galvalume steel. Galvalume steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

Thickness 0.23-1.2mm (BMT) |

Zinc Coating 80-275g/m2 |

Color According to RAL color fan |

Internal Diameter 508mm or 610mm |

Coil Weight 4-8MT |

Quality Commercial and structural quality |

Paint Polyester paint for topside, epoxy for reverse |

Standard JIS G 3312, ASTM A755M, EN 10169 |

Base Steel Grade SGCC,SGCD,DX51D+Z,DX52D+Z;S200GD,S220GD, S280GD,S350GD,CS,FS,SS |

Chemical Composition Of Aluzinc Steel

C | Si | Mn | P |

0.04-0.06% | 0.01-0.03% | 0.18-0.22% | 0.014-0.016% |

Technical Data Of Prepainted Galvanized Steel

Yield Strength | (Mpa) 280-320 |

Tensile Strength | (Mpa) 340-390 |

Elongation | 20%-30% |

Reverse Impact | 9J |

T-bending | ≥2T |

Pencil Hardness | ≥2H |

Duration Of Salt Spray Test | 500 H |

Bending At 180 Degree | No crack, purling and fraction |

Application Of Aluzinc Steel

Outdoor:

roof, roof structure, surface sheet of balcony,

frame of window, door, door of garage, roller shutter door, booth, Persian blinds, cabana, etc.

In door:

door, isolater, frame of door, light steel structure of house, home electronic appliances, etc.

Packaging & Delivery Of Aluzinc Steel

Anti-damp paper inside full wrapped with plastic film, iron sheet outside on wooden pallet in 20 feet container with 25mt.

- Q: How are steel coils tested for mechanical properties?

- Steel coils are tested for mechanical properties through various methods, including tensile testing, hardness testing, and impact testing. Tensile testing involves stretching the steel coil until it breaks to determine its strength, elasticity, and ductility. Hardness testing measures the resistance of the steel to indentation or scratching, indicating its overall toughness. Impact testing involves striking the coil with a pendulum to assess its ability to absorb energy without fracturing. These tests help evaluate the quality and performance of steel coils in different applications.

- Q: im buying a new guitar,, it has a built in tuner and its semi acoustic (can be plugged into an amplifier) ,, im trying to choose which strings are better ,, steel or nylon..?

- Musical style speaks volumes when it comes to this issue. Those who want high volume will be unhappy with unamplified nylon string guitars. From my perspective, the basic difference between steel and nylon is this: steel strings ring and nylon strings resonate. The volume produced by steel is generally much greater than nylon but, to my way of thinking, the sound resonance produced by the wood of your guitar is largely masked by steel strings. If you have a decently made guitar (generally, around a thousand dollars and up), the sound interplay between the wood and the strings in a nylon guitar is magical across the entire frequency range. With a steel string guitar, the sound produced by the vibrating string overpowers the wood resonance at all but low frequencies. Personally, I'll take a nylon string guitar any day for the sensitivity gained from the interplay between wood and vibrating string.

- Q: What are the quality control measures for steel coils?

- Quality control measures for steel coils include conducting visual inspections to check for surface defects, such as scratches, dents, or discoloration. Measurements are taken to ensure the proper dimensions and thickness of the steel coil. Mechanical properties, such as tensile strength and yield strength, are also tested to ensure they meet the required standards. Additionally, tests may be performed to check for coatings, such as zinc or paint, to ensure they are applied correctly and adhere properly to the steel surface.

- Q: What are the applications of steel coils?

- Steel coils are utilized across a wide array of industries due to their versatility and durability. The construction industry, in particular, heavily relies on steel coils for structural purposes. These coils can be shaped and molded into different sizes and forms to create essential components like beams, columns, and other structural elements needed in buildings, bridges, and infrastructure projects. Another significant field that benefits from steel coils is the automobile manufacturing industry. Steel coils are instrumental in producing various parts and components of vehicles, including body panels, chassis, frames, and engine parts. The exceptional strength and durability of steel make it an ideal material for ensuring the safety and longevity of automobiles. Moreover, steel coils play a crucial role in the production of household appliances such as refrigerators, washing machines, and stoves. Steel's versatility allows it to be easily molded and shaped into different configurations, making it suitable for various appliance components. In the energy sector, steel coils find extensive use in the manufacturing of power generation equipment and pipelines. Turbines, generators, and other equipment used in power plants are made from steel coils. Additionally, steel coils are employed in constructing pipelines for the transportation of oil, gas, and other fluids. Furthermore, steel coils are widely employed in the fabrication of storage tanks, industrial machinery, and agricultural equipment. They are also utilized in the production of furniture, shelving units, and various metal products. In summary, steel coils play a vital role in numerous industries, including construction, automotive, appliance manufacturing, energy, and others. The strength, durability, and versatility of steel make it an indispensable material for both structural and functional purposes.

- Q: Can steel coils be cut to length?

- Yes, steel coils can be cut to length using various cutting methods such as shearing, slitting, or sawing.

- Q: I'm just wondering what the best steel would be for an edc/hunting knife that could put up with alot of abuse.

- D2 and O2 steels are nice. They are expensive, but hold an edge extremely well. S30V is nice also. It's a more stain-resistant steel that holds an edge very well. For outdoor hiking/camping knives, it's tough to beat good old 1095 carbon steel. Sure it will rust, but it's tough as nails, not brittle, holds an edge pretty well, and easy to sharpen...and it's pretty cheap. Other steels, AUS8 is an ok cheap steel. It's stain resistant and cheap. AUS6 isn't worth the time or effort. Buck knives does an excellent job of heat treating 420 stainless to become very hard. Their knives are excellent considering 420 stainless is typically soft steel.

- Q: Can steel coils be recoiled?

- Yes, steel coils can be recoiled. The process of recoiling involves rewinding the steel coil onto a different reel, typically to adjust the coil size or to improve its shape.

- Q: a steel abr sells for about 879 now...a mith just over 1kany suggestions on which-keyword WHICH steel item to make-which is the best-exp wise, and steel bar conservative wise.

- Mining okorder /

- Q: I know that carbon steels and alloy steels are different but are carbon steels still alloys?Thanks!

- Yes. it's an alloy of iron and carbon. Carbon steel can either mean plain carbon steel which is steel that doesn't have significant amounts of other elements, like chromium, manganese, or molybdenum. It can also be used to refer to ANY steel that is NOT a stainless steel. Alloy steel is any steel that has greater than 1% of other elements added to it besides carbon. Stainless steel might be in a certain sense be considered alloy steel but I think most people in the steel business consider it as it's own separate material from carbon steels. Many stainless steels contain only trace amounts of carbon, so they should rightly be considered iron-chromium alloys, not steel, which by default refers to iron-carbon alloys. Note that nearly all modern carbon steels also contain 0.2%-0.5% manganese and silicon. Even steels that are otherwise considered plain carbon and not alloy steels. Mn and Si are added because they prevent defects in cast steel ingots, and hot rolled items like billets and plates. However at low levels they don't affect the properties of the steel greatly.

- Q: I'm ordering a Pair of tongs(a tool used to dig quahogs in bays that scrapes the bottom constantly) and what type of metal would be the best to fabricate it, steel or stainless steel?

- Stainless okorder

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2003 |

| Annual Output Value | US$1 Million - US$2.5 Million |

| Main Markets | Southern Asia; America; South America; Eastern Europe |

| Company Certifications | ISO 9000 ISO 14000 OHSAS 18000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | 100 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 200,000 square meters |

| No. of Production Lines | 14 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

Dried Aluzinc Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- T/T or L/C

- Min Order Qty:

- 25mt m.t.

- Supply Capability:

- 5000mt/per month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords