Colored Aluminum Trim Coil

Colored Aluminum Trim Coil Related Searches

Painted Aluminum Trim Coil Textured Aluminum Trim Coil Colored Aluminum Coil Vinyl Coated Aluminum Trim Coil Color Coated Aluminum Coil Painting Aluminum Trim Coil Trim Coil Aluminum Pvc Coated Aluminum Trim Coil Alcoa Aluminum Trim Coil Colors Aluminum Siding Trim Coil Alcoa Aluminum Trim Coil Black Aluminum Trim Coil White Aluminum Trim Coil Poly Aluminum Trim Coil Red Aluminum Trim Coil Bending Aluminum Trim Coil Mastic Aluminum Trim Coil Copper Colored Aluminum Coil Clay Aluminum Trim Coil Textured Aluminum Coil Alside Aluminum Trim Coil Colors Wood Grain Aluminum Trim Coil Pvc Aluminum Trim Coil Installing Aluminum Trim Coil Aluminum Vinyl Siding Trim Coil Best Aluminum Trim Coil Bronze Aluminum Trim Coil Woodgrain Aluminum Trim Coil Aluminum Trim Coil White Mastic Aluminum Trim Coil ColorsColored Aluminum Trim Coil Supplier & Manufacturer from China

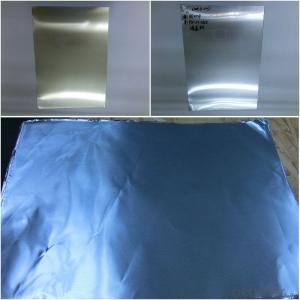

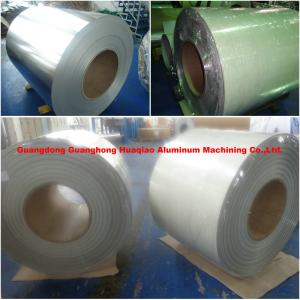

Colored Aluminum Trim Coil is a versatile product that consists of aluminum coils with a colored finish, offering a wide range of applications in various industries. This product is known for its durability, corrosion resistance, and aesthetic appeal, making it a popular choice for construction, automotive, and architectural projects. The colored aluminum trim coil can be used in a variety of ways, such as for decorative trims, edge protection, and sealing purposes. Its adaptability to different environments and surfaces ensures that it remains a sought-after material in the market.In various application and usage scenarios, colored aluminum trim coil stands out for its ability to enhance the visual appeal and protect structures from external elements. It is commonly used in residential and commercial buildings for window and door frames, as well as in automotive industries for body trims and protective guards. The product's resistance to weathering and fading ensures that it maintains its vibrant color and appearance over time, providing a long-lasting solution for various applications. This makes it an ideal choice for both indoor and outdoor use, where durability and aesthetics are of paramount importance.

Okorder.com is a reputable wholesale supplier of colored aluminum trim coil, boasting a large inventory that caters to the diverse needs of customers worldwide. The company is committed to providing high-quality products at competitive prices, ensuring that clients receive the best value for their investment. With a vast selection of colored aluminum trim coils available, Okorder.com is the go-to destination for businesses and individuals looking to purchase this versatile and durable material.

Hot Products