Aluminum Color Coils with Different Thickness and Width

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum Coils with Different Thickness and Width

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3A21 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum or paper |

7) Coil Inner diameter | 75mm, 150mm, 200mm, 300mm, 405mm, 505mm or as required |

8) Protective film can be added

2. Application of Aluminum Coils with Different Thickness and Width

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum Coils with Different Thickness and Width

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

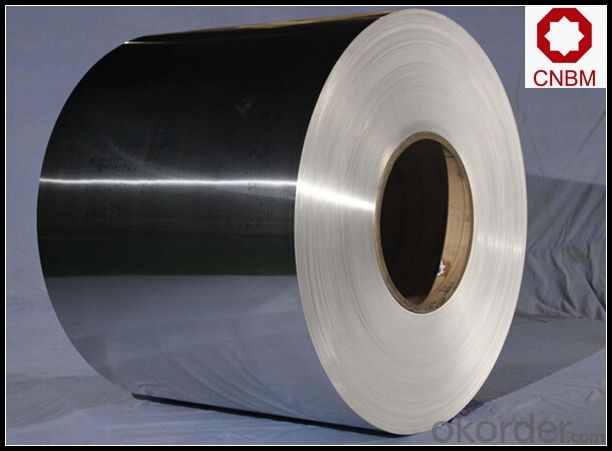

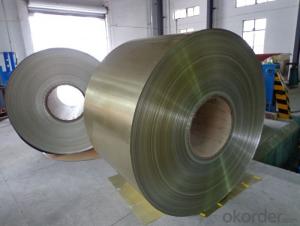

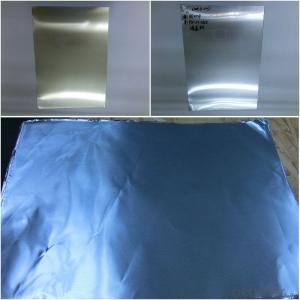

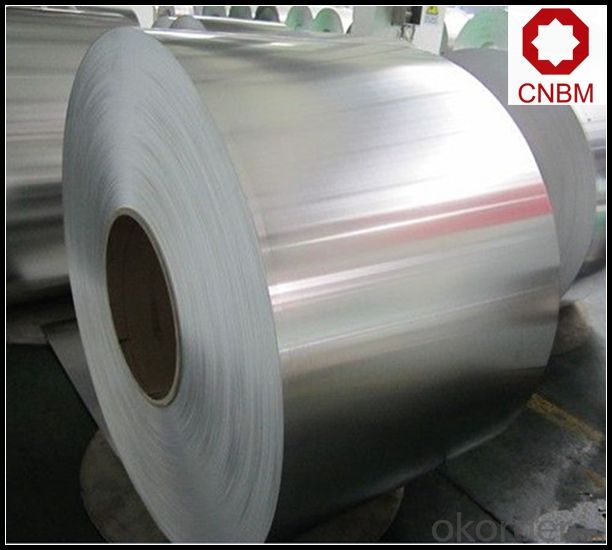

5. Image of Aluminum Coils with Different Thickness and Width

6. Package and shipping of Aluminum Coils with Different Thickness and Width

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the environmental regulations concerning the use of aluminum coils?

- <p>Yes, there are environmental regulations that govern the use of aluminum coils. These regulations vary by country and region but often include restrictions on emissions, waste disposal, and recycling requirements. For instance, in the United States, the Environmental Protection Agency (EPA) enforces rules that control the release of pollutants from aluminum production facilities. Additionally, there are guidelines for the proper disposal of aluminum waste to prevent environmental contamination. Recycling regulations also encourage the reuse of aluminum coils to reduce the environmental impact of mining and production. Compliance with these regulations is crucial for businesses that manufacture or use aluminum coils to avoid penalties and ensure sustainable practices.</p>

- Q: Which is better composite or aluminum, and what are some main differences between the two?

- I believe that composite is a lot better, I bought the orange easton stealth bat and I love it. Once they are broken in, composite is deadly. But Its really bad to use a composite bat in the cold because they dent easier. I recommend one piece aluminum for cold weather like the easton v12 or the tpx omaha. Easton sv12's are good too, but its not one piece aluminum. You just have to remember that a metal bat is a metal bat and its if you are a good hitter, it wont really matter what you use.

- Q: Is it possible to utilize aluminum coil in the welding process?

- <p>Yes, aluminum coil can be used for welding. It is commonly used as a filler material in processes like MIG (Metal Inert Gas) welding, where it is fed continuously into the weld pool to create a joint. Aluminum welding requires specific techniques and equipment due to its high thermal conductivity and the need to prevent oxidation. The aluminum coil must be of high quality and clean to ensure a strong, corrosion-resistant weld.</p>

- Q: Hi, I have a large bag of aluminium sulfate that I would like to use to turn my hydrangeas blue but there are no instructions on the pack, can anyone tell me how much I need (mixed with water)

- Si es tu profesora l. a. que te corrigio el blunders, sabe, quedate tranquila. El aluminio tiene número de oxidación +3 y el radical sulfato -2, intercambiando número de oxidación por atomicidad, para equilibrar, te queda lo que dijo tu profesora...

- Q: Are aluminum coils suitable for food storage containers?

- Yes, aluminum coils are suitable for food storage containers. Aluminum is a popular material choice for food storage containers due to its various advantageous properties. Firstly, aluminum is lightweight, making it easy to handle and transport. Additionally, aluminum has excellent thermal conductivity, which means it can cool down or heat up quickly, making it ideal for both hot and cold food storage. Moreover, aluminum is resistant to corrosion and does not react with acidic or alkaline foods, ensuring that the taste and quality of the food remain intact. Furthermore, aluminum is a sustainable and recyclable material, making it environmentally friendly. However, it is important to note that aluminum containers should be lined with a food-grade coating to prevent any potential reaction between the metal and the food, especially acidic foods. Overall, aluminum coils are a suitable choice for food storage containers due to their lightweight nature, thermal conductivity, corrosion resistance, and recyclability.

- Q: What is the expected lead time for manufacturing aluminum coils?

- The expected lead time for manufacturing aluminum coils can vary depending on several factors. These factors include the complexity of the coil design, the size and quantity of the coils being manufactured, the availability of raw materials, and the production capacity of the manufacturing facility. In general, the lead time for manufacturing aluminum coils can range from a few weeks to several months. For standard-sized coils with a simple design and readily available raw materials, the lead time is usually on the shorter end of the spectrum. On the other hand, if the coils have a complex design or require specialized materials, the lead time may be longer. Additionally, the production capacity of the manufacturing facility plays a significant role in determining the lead time. Facilities with higher production capacities can typically manufacture and deliver aluminum coils more quickly than those with lower capacities. It is important to consult with the specific manufacturer to get an accurate estimate of the expected lead time for manufacturing aluminum coils. They will be able to assess the specific requirements of the project and provide a timeframe that aligns with those requirements.

- Q: Are aluminum coils suitable for high-gloss applications?

- Aluminum coils are indeed suitable for high-gloss applications. Aluminum has excellent reflective properties and can achieve a high level of shine and gloss when properly treated and finished. The metal's smooth surface and reflective nature allow it to enhance the appearance of high-gloss finishes, making it an ideal choice for applications where a shiny and polished look is desired. In addition to its aesthetic benefits, aluminum also offers several practical advantages for high-gloss applications. It is lightweight, durable, and resistant to corrosion, making it a long-lasting and low-maintenance option. Aluminum coils are also highly malleable, allowing them to be easily formed into various shapes and sizes, which is crucial for achieving the desired high-gloss design. Furthermore, aluminum coils can be coated with a variety of finishes, such as anodized coatings or high-quality paint systems, to enhance their durability and glossiness. These coatings provide an additional layer of protection against scratches, fading, and other forms of wear and tear, ensuring that the high-gloss appearance is maintained over time. In summary, aluminum coils are well-suited for high-gloss applications due to their reflective properties, versatility, and durability. When properly treated and finished, aluminum can provide a stunning and long-lasting glossy finish, making it a popular choice for various industries, including automotive, architecture, and interior design.

- Q: Can aluminum coils be used in the production of aluminum composite roofs?

- Yes, aluminum coils can be used in the production of aluminum composite roofs. Aluminum coils are commonly used in the manufacturing process of aluminum composite roofs due to their durability, lightweight nature, and ability to resist corrosion. The coils can be easily formed and shaped into the desired profile for the roof, ensuring a seamless and aesthetically pleasing finish. Additionally, aluminum offers excellent thermal and sound insulation properties, making it an ideal choice for roofing applications. Its high strength-to-weight ratio also contributes to the overall structural integrity of the roof. Overall, using aluminum coils in the production of aluminum composite roofs provides a reliable and long-lasting roofing solution.

- Q: Will aluminum foil go off in a metal detector

- Aluminum Detector

- Q: Are aluminum coils suitable for electrical conductivity applications?

- Aluminum coils are well-suited for applications that require electrical conductivity. Aluminum is renowned for its exceptional electrical conductivity, ranking second only to copper among commonly used metals. With about 61% of the conductivity of copper, it is a dependable choice for various electrical purposes. Aluminum coils find extensive use in power transmission, transformers, and electrical motors due to their efficient electrical conduction capabilities. Moreover, their lightweight nature makes handling and installation in electrical systems easier. However, it is important to acknowledge that aluminum has higher resistance than copper, necessitating larger aluminum conductors to achieve the same electrical performance. All in all, aluminum coils serve as a fitting choice for applications that require electrical conductivity.

Send your message to us

Aluminum Color Coils with Different Thickness and Width

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords