All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the applications of aluminum coils in the manufacturing of aluminum garage doors?

Aluminum coils are used in the manufacturing of aluminum garage doors primarily for their lightweight yet sturdy nature, which allows for easy installation and operation of the doors. Additionally, the coils provide excellent corrosion resistance, ensuring long-lasting durability for the garage doors. The malleability of aluminum also enables the creation of various designs and styles, allowing manufacturers to offer a wide range of options to customers. Furthermore, aluminum coils can be easily recycled, making them an environmentally friendly choice for garage door manufacturing.

How are aluminum coils used in the production of aluminum composite panels?

Aluminum coils are used in the production of aluminum composite panels as they serve as the raw material for constructing the panel's core. The coils are unwound and then fed through a series of rollers and machines that apply a polyethylene or mineral-filled core material to both sides of the aluminum coil. This process creates a sandwich-like structure, where the aluminum coil acts as the outer layers of the composite panel while the core material provides strength and insulation. The resulting aluminum composite panels are lightweight, durable, and have excellent fire resistance, making them ideal for various applications in the construction industry.

What is the role of stress relief annealing in aluminum coil production for specific applications?

The role of stress relief annealing in aluminum coil production for specific applications is to remove any internal stresses that have developed during the manufacturing process. This annealing process helps to improve the mechanical properties and dimensional stability of the aluminum coils, making them suitable for specific applications such as automotive parts, aerospace components, and electrical conductors.

How are aluminum coils used in the construction industry?

Aluminum coils are widely used in the construction industry for various purposes. They are primarily used for roofing applications, as the coils can be easily formed into sheets or panels to create durable and lightweight roofs. Additionally, aluminum coils are used in the production of gutters, downspouts, and fascia, providing a corrosion-resistant and low-maintenance solution for these components. Moreover, these coils are utilized in the construction of HVAC systems, where they are formed into fins and tubes for efficient heat transfer. Overall, aluminum coils play a vital role in construction, offering versatility, durability, and energy efficiency in various applications.

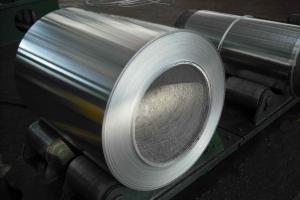

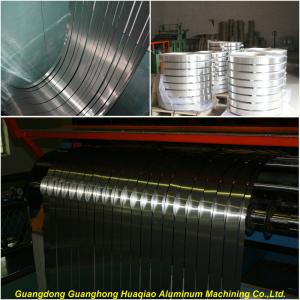

Wholesale Aluminum Coils from supplier in Tajikistan

Whether you require Aluminum Coils for construction, transportation, or packaging purposes, we have a wide selection of high-quality products to meet your specific needs. Our team of dedicated professionals is committed to delivering exceptional customer service and ensuring your satisfaction throughout the entire procurement process.

In addition to our vast product range, we also offer competitive pricing and flexible payment options to suit your budget and requirements. We understand the importance of timely delivery, and our logistics team works diligently to ensure that your Aluminum Coils are delivered to your doorstep in a timely manner.

Furthermore, our technical support team is always available to provide you with expert advice and guidance on the best Aluminum Coils products for your project. Whether you have questions about specifications, application techniques, or any other technical aspect, we are here to assist you.

By choosing us as your supplier of Aluminum Coils in Tajikistan, you can benefit from the resources and expertise of a Fortune Global 500 company. We are dedicated to helping you succeed in your projects and look forward to serving you with our comprehensive sales, quotation, and technical support services. Contact us today to discuss your Aluminum Coils requirements and let us be your trusted partner in Tajikistan.

In addition to our vast product range, we also offer competitive pricing and flexible payment options to suit your budget and requirements. We understand the importance of timely delivery, and our logistics team works diligently to ensure that your Aluminum Coils are delivered to your doorstep in a timely manner.

Furthermore, our technical support team is always available to provide you with expert advice and guidance on the best Aluminum Coils products for your project. Whether you have questions about specifications, application techniques, or any other technical aspect, we are here to assist you.

By choosing us as your supplier of Aluminum Coils in Tajikistan, you can benefit from the resources and expertise of a Fortune Global 500 company. We are dedicated to helping you succeed in your projects and look forward to serving you with our comprehensive sales, quotation, and technical support services. Contact us today to discuss your Aluminum Coils requirements and let us be your trusted partner in Tajikistan.