All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

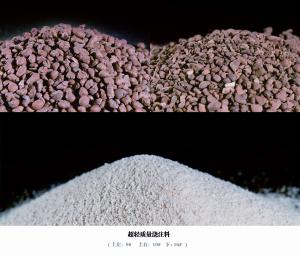

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

Can monolithic refractories be used for lining copper holding furnaces?

Yes, monolithic refractories can be used for lining copper holding furnaces. Monolithic refractories are versatile and can withstand high temperatures, making them suitable for lining furnaces used for holding molten copper. They provide excellent thermal insulation and have good resistance to thermal shock and chemical attack, which are essential properties for lining copper holding furnaces.

How do monolithic refractories perform in high-velocity solid particle environments?

Monolithic refractories perform well in high-velocity solid particle environments due to their inherent properties of high thermal shock resistance, abrasion resistance, and erosion resistance. They can withstand the impact of solid particles at high velocities without significant damage or degradation, making them suitable for applications such as furnace linings, incinerators, and boilers where solid particles are present in the gas streams.

What is the density of monolithic refractories?

The density of monolithic refractories typically ranges from 2.5 to 3.5 grams per cubic centimeter (g/cm³).

What are the different bonding systems used in monolithic refractories?

The different bonding systems used in monolithic refractories include hydraulic bonding, chemical bonding, and ceramic bonding. Hydraulic bonding involves the use of water to create a bond between refractory particles. Chemical bonding utilizes chemical reactions to form bonds, such as the use of phosphates or silicates. Ceramic bonding involves the formation of a ceramic matrix through the firing of refractory particles at high temperatures.

How do monolithic refractories handle chemical reactions?

Monolithic refractories are designed to withstand chemical reactions due to their unique composition and structure. They possess excellent chemical resistance and stability, allowing them to handle various reactive environments. Additionally, their monolithic nature eliminates joints and seams, minimizing the risk of chemical attack and penetration. However, the specific performance of monolithic refractories in chemical reactions depends on factors such as temperature, type of chemical reaction, and the composition of the refractory material.

Wholesale Monolithic Refractories from supplier in Tajikistan

Our team of experts is highly knowledgeable about the local market conditions and regulations, ensuring that we can offer tailored solutions to meet your specific requirements. We have a wide range of Monolithic Refractories products available, including castables, plastics, and ramming materials, among others.

In addition to supplying high-quality products, we also offer comprehensive sales support services. Our dedicated sales team will work closely with you to understand your needs and provide competitive quotations for your projects. We strive to offer the best prices without compromising on the quality of our products.

Furthermore, we understand that technical support is crucial in the successful implementation of projects. Our experienced technical team is available to provide guidance and assistance throughout the entire process, from product selection to installation and maintenance. We can also provide on-site training for your staff to ensure proper handling and application of our Monolithic Refractories.

As a subsidiary of CNBM, one of the largest building materials companies in the world, we have access to a global network of resources and expertise. This allows us to stay at the forefront of the industry and offer the latest innovations in Monolithic Refractories. Our commitment to quality and customer satisfaction is evident in our long-standing relationships with clients in Tajikistan.

Whether you are in need of Monolithic Refractories for industrial furnaces, kilns, or any other high-temperature applications, we have the products and services to meet your needs. Contact us today to discuss your specific requirements and let us help you find the right solution for your projects in Tajikistan.

In addition to supplying high-quality products, we also offer comprehensive sales support services. Our dedicated sales team will work closely with you to understand your needs and provide competitive quotations for your projects. We strive to offer the best prices without compromising on the quality of our products.

Furthermore, we understand that technical support is crucial in the successful implementation of projects. Our experienced technical team is available to provide guidance and assistance throughout the entire process, from product selection to installation and maintenance. We can also provide on-site training for your staff to ensure proper handling and application of our Monolithic Refractories.

As a subsidiary of CNBM, one of the largest building materials companies in the world, we have access to a global network of resources and expertise. This allows us to stay at the forefront of the industry and offer the latest innovations in Monolithic Refractories. Our commitment to quality and customer satisfaction is evident in our long-standing relationships with clients in Tajikistan.

Whether you are in need of Monolithic Refractories for industrial furnaces, kilns, or any other high-temperature applications, we have the products and services to meet your needs. Contact us today to discuss your specific requirements and let us help you find the right solution for your projects in Tajikistan.

Hot Search

- Monolithic Refractories in Somalia

- Ceramic Fiber Products in Lebanon

- Refractory Bricks in Dominican

- Raw Materials For Refractory in Tuvalu

- Raw Materials For Refractory in Gabon

- Monolithic Refractories in Liechtenstein

- Monolithic Refractories in Uzbekistan

- Refractory Bricks in Kazakhstan

- Raw Materials For Refractory in Switzerland

- Refractory Bricks in Haiti