All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

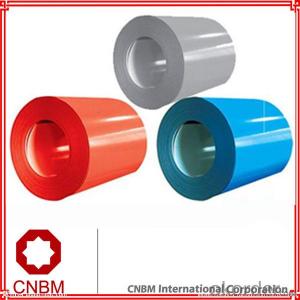

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What measures are taken to ensure the safety of workers handling steel coils?

There are several measures taken to ensure the safety of workers handling steel coils. Firstly, workers are provided with appropriate personal protective equipment such as gloves, safety glasses, and hard hats to protect them from potential hazards. Secondly, proper training is provided to workers on how to handle steel coils safely, including techniques to prevent injuries while lifting or moving them. Additionally, safety protocols are established to ensure that workers follow proper procedures while working with steel coils, including guidelines for storage, stacking, and transportation. Regular maintenance checks are conducted on equipment and machinery used in handling steel coils to prevent any malfunctions or accidents. Finally, a strong safety culture is promoted within the workplace, encouraging workers to report any safety concerns and fostering a collaborative environment where safety is given top priority.

How do steel coil properties vary when used in the marine and shipbuilding industry?

In the marine and shipbuilding industry, steel coil properties vary due to the specific requirements and challenges posed by the marine environment. Steel used in this industry needs to have excellent corrosion resistance to withstand the constant exposure to saltwater and harsh weather conditions. Additionally, it should possess high tensile strength to provide structural integrity and durability to the ships and offshore structures. Steel coils used in the marine and shipbuilding industry often undergo specialized treatments like galvanization or coating to enhance their resistance to corrosion and ensure long-term performance in marine environments.

What is the purpose of coil end welding quality checks?

The purpose of coil end welding quality checks is to ensure that the welding process used to join the ends of coils is of high quality and meets the required standards. These checks help identify any potential defects or issues in the welding, such as incomplete fusion or porosity, which could affect the overall performance and integrity of the coils. By conducting these quality checks, manufacturers can ensure the reliability and durability of the coils, thereby increasing customer satisfaction and reducing the risk of product failures.

Wholesale Steel Coils from supplier in Tajikistan

Our team of experts is committed to delivering high-quality steel coils that meet your specific requirements. Whether you need hot-rolled coils, cold-rolled coils, or galvanized coils, we have a wide range of options to choose from. Our sales team will work closely with you to understand your needs and provide you with competitive pricing and timely quotations.

In addition to sales, we also provide technical support to ensure that you have the necessary information and guidance to make informed decisions. Our technical experts are well-versed in the specifications and applications of steel coils, and they can assist you in selecting the right product for your project.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources, ensuring a reliable supply chain and timely delivery of your steel coils. Our strong presence in the Tajikistan market enables us to understand the local industry trends and requirements, allowing us to offer valuable expertise for your projects.

We are committed to providing a seamless procurement experience for our customers. From initial inquiry to final delivery, our dedicated team will assist you every step of the way, ensuring that your steel coil requirements are met efficiently and effectively.

Contact us today to experience our comprehensive services and expertise in supplying steel coils in Tajikistan.

In addition to sales, we also provide technical support to ensure that you have the necessary information and guidance to make informed decisions. Our technical experts are well-versed in the specifications and applications of steel coils, and they can assist you in selecting the right product for your project.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources, ensuring a reliable supply chain and timely delivery of your steel coils. Our strong presence in the Tajikistan market enables us to understand the local industry trends and requirements, allowing us to offer valuable expertise for your projects.

We are committed to providing a seamless procurement experience for our customers. From initial inquiry to final delivery, our dedicated team will assist you every step of the way, ensuring that your steel coil requirements are met efficiently and effectively.

Contact us today to experience our comprehensive services and expertise in supplying steel coils in Tajikistan.