All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

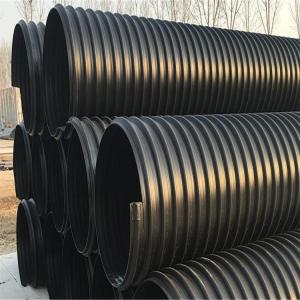

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How are steel pipes used in the development of wastewater treatment plants and sewage systems?

Steel pipes are used in the development of wastewater treatment plants and sewage systems due to their durability, strength, and corrosion resistance. These pipes are used for the transportation of both raw sewage and treated wastewater, ensuring efficient flow and preventing any leakage or contamination. Additionally, steel pipes are often utilized in the construction of various components within these systems, such as pumping stations and chemical dosing units, further contributing to the overall effectiveness and longevity of wastewater treatment plants and sewage systems.

How are steel pipes used in the construction of suspension bridges and cable-stayed bridge structures?

Steel pipes are commonly used in the construction of suspension bridges and cable-stayed bridge structures due to their high strength and durability. These pipes are primarily utilized for the main load-bearing elements, such as the bridge towers and piers, as well as for the suspension cables or stay cables that support the bridge deck. The steel pipes provide the necessary structural support, enabling these types of bridges to span long distances and withstand heavy loads while maintaining stability and safety.

How does the choice of steel pipe material affect its performance in high-temperature ovens and furnaces?

The choice of steel pipe material significantly affects its performance in high-temperature ovens and furnaces. Steel pipes made from materials with high heat resistance, such as stainless steel or heat-resistant alloys, can withstand the extreme temperatures without losing their structural integrity. These materials have excellent corrosion resistance, oxidation resistance, and thermal stability, making them ideal for such environments. On the other hand, using low-quality or non-heat-resistant steel materials can lead to pipe deformation, accelerated corrosion, and reduced overall performance, compromising the safety and efficiency of the oven or furnace.

How do you protect steel pipes from corrosion?

One common method to protect steel pipes from corrosion is by applying a coating or paint. This helps create a barrier between the metal surface and the environment, preventing direct contact with moisture and chemicals that can cause corrosion. Additionally, cathodic protection techniques, such as using sacrificial anodes or applying impressed current, can be employed to further safeguard the steel pipes from corrosion. Regular inspections and maintenance are also essential to identify and address any potential corrosion issues promptly.

Wholesale Steel Pipes from supplier in Niger

We are a Steel Pipes supplier serving the Niger, mainly engaged in the sale, quotation, and technical support services of various Steel Pipes products in the Niger region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Steel Pipes procurement services in the Niger. Not only do we have a wide range of Steel Pipes products, but after years of market development in the Niger, we can also provide valuable experience for your projects.