All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What is the role of aluminum coils in the production of aluminum composite panels for signage?

The role of aluminum coils in the production of aluminum composite panels for signage is to serve as the base material for the panels. These coils are made from high-quality aluminum, which is then processed and coated with various protective layers. The coils are responsible for providing the structural strength, durability, and stability to the final composite panels.

What are the differences between cast and rolled aluminum coils?

The main differences between cast and rolled aluminum coils lie in their manufacturing processes. Cast aluminum coils are produced by pouring molten aluminum into a mold, which creates a rougher surface texture and may contain impurities. On the other hand, rolled aluminum coils are made by passing aluminum ingots through a series of rolling mills, which result in a smoother and more uniform surface. Additionally, cast aluminum coils are generally thicker and used for applications that require strength, while rolled aluminum coils are thinner and preferred for applications that require flexibility and formability.

What are the best practices for handling and disposing of aluminum coil lubricants?

The best practices for handling and disposing of aluminum coil lubricants typically include following the manufacturer's guidelines and local regulations. It is important to store lubricants in a cool and dry area, away from direct sunlight and sources of ignition. When handling lubricants, wearing appropriate personal protective equipment, such as gloves and goggles, is recommended. Additionally, it is crucial to prevent spills or leaks and clean them up promptly to minimize environmental impact. When it comes to disposing of aluminum coil lubricants, it is advisable to consult with local waste management authorities to understand the proper methods and regulations. Recycling or reusing lubricants whenever possible is also a sustainable practice to consider.

What is the thickness range of aluminum coils?

The thickness range of aluminum coils can vary depending on the specific application and industry requirements. Generally, aluminum coils can have a thickness range of 0.006 to 0.25 inches (0.15 to 6.35 mm).

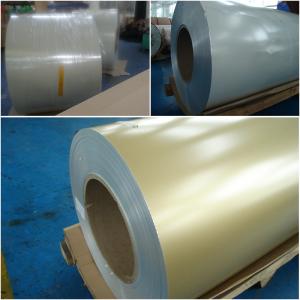

Wholesale Aluminum Coils from supplier in Israel

Our team of experienced professionals is dedicated to providing excellent customer service, ensuring that your procurement process is smooth and hassle-free. We are committed to delivering high-quality Aluminum Coils that meet international standards and specifications.

In addition to our wide range of products, we also offer competitive pricing and flexible payment options to suit your budget and project requirements. Our sales representatives are available to provide expert advice and guidance, helping you make informed decisions about the best Aluminum Coils for your applications.

Furthermore, our technical support team is always ready to assist you with any technical queries or challenges you may encounter. We understand the importance of timely and accurate information, and we strive to provide the necessary support to keep your projects on track.

At CNBM, we prioritize customer satisfaction and aim to build long-term relationships based on trust and reliability. We are confident in our ability to meet your Aluminum Coils needs in Israel and look forward to serving you. Contact us today to discuss your requirements and discover how we can assist you.

In addition to our wide range of products, we also offer competitive pricing and flexible payment options to suit your budget and project requirements. Our sales representatives are available to provide expert advice and guidance, helping you make informed decisions about the best Aluminum Coils for your applications.

Furthermore, our technical support team is always ready to assist you with any technical queries or challenges you may encounter. We understand the importance of timely and accurate information, and we strive to provide the necessary support to keep your projects on track.

At CNBM, we prioritize customer satisfaction and aim to build long-term relationships based on trust and reliability. We are confident in our ability to meet your Aluminum Coils needs in Israel and look forward to serving you. Contact us today to discuss your requirements and discover how we can assist you.