All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What is the role of aluminum coils in the production of aluminum storefronts and entrances?

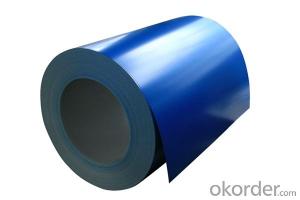

The role of aluminum coils in the production of aluminum storefronts and entrances is to serve as the primary raw material for fabrication. These coils are processed and cut into the desired shape and size to create the frames, panels, and other components of the storefronts and entrances. The use of aluminum coils ensures the production of lightweight, durable, and corrosion-resistant structures that are essential for commercial buildings.

What is the role of aluminum coils in the production of aluminum awnings and canopies?

The role of aluminum coils in the production of aluminum awnings and canopies is crucial. These coils are used as the primary material for manufacturing these structures. The aluminum coils are shaped, cut, and formed into the desired shape and size to create the framework of the awnings and canopies. The use of aluminum coils ensures that the final product is lightweight, durable, and resistant to corrosion, making it ideal for outdoor applications.

What are the advantages of using aluminum coils in the automotive industry?

There are several advantages of using aluminum coils in the automotive industry. Firstly, aluminum coils are lightweight, which helps in reducing the overall weight of the vehicle. This, in turn, improves fuel efficiency and reduces carbon emissions. Additionally, aluminum coils have excellent corrosion resistance properties, making them highly durable and long-lasting. They also possess high thermal conductivity, enabling efficient heat dissipation and enhancing the performance of various automotive components. Moreover, aluminum coils can be easily molded into complex shapes, allowing for design flexibility and enhancing the aesthetic appeal of vehicles. Overall, the use of aluminum coils in the automotive industry offers improved fuel economy, durability, performance, and design possibilities.

What are the regulations and standards for aluminum coil manufacturing?

The regulations and standards for aluminum coil manufacturing vary depending on the country and industry. However, some common requirements include compliance with international standards such as ISO 9001 for quality management systems and ISO 14001 for environmental management systems. In addition, manufacturers may need to adhere to specific regulations related to health and safety, such as OSHA guidelines in the United States. Other standards may include specifications on the chemical composition, mechanical properties, and dimensions of the aluminum coils, ensuring their suitability for various applications. It is essential for aluminum coil manufacturers to stay updated with the latest regulations and standards to ensure the production of high-quality and compliant products.

Wholesale Aluminum Coils from supplier in Niue

Whether you require Aluminum Coils for construction, transportation, or any other industry, we have the expertise and resources to meet your specific needs. Our team of professionals is dedicated to delivering high-quality products and excellent customer service.

With our comprehensive sales and quotation services, we can assist you in selecting the right Aluminum Coils for your project. Our technical support team is also available to provide guidance on product specifications, installation, and maintenance.

As a subsidiary of CNBM, a Fortune Global 500 company, we have a strong network of suppliers and manufacturers, ensuring a reliable and consistent supply of Aluminum Coils in Niue. Our procurement solutions are designed to streamline the purchasing process, saving you time and resources.

We understand the unique requirements and challenges of the Niuean market. With years of experience in the region, we have developed valuable insights and expertise that can benefit your projects. Whether you are a contractor, distributor, or end-user, we are committed to helping you achieve success.

Contact us today to discuss your Aluminum Coils requirements in Niue. Our dedicated team is ready to assist you and provide customized solutions that meet your specific needs.

With our comprehensive sales and quotation services, we can assist you in selecting the right Aluminum Coils for your project. Our technical support team is also available to provide guidance on product specifications, installation, and maintenance.

As a subsidiary of CNBM, a Fortune Global 500 company, we have a strong network of suppliers and manufacturers, ensuring a reliable and consistent supply of Aluminum Coils in Niue. Our procurement solutions are designed to streamline the purchasing process, saving you time and resources.

We understand the unique requirements and challenges of the Niuean market. With years of experience in the region, we have developed valuable insights and expertise that can benefit your projects. Whether you are a contractor, distributor, or end-user, we are committed to helping you achieve success.

Contact us today to discuss your Aluminum Coils requirements in Niue. Our dedicated team is ready to assist you and provide customized solutions that meet your specific needs.