All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

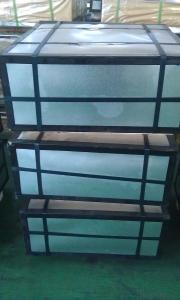

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How is the tin coating on electrolytic tinplate coil evaluated for adhesion?

The tin coating on electrolytic tinplate coil is evaluated for adhesion through various methods such as a bend test, tape test, cross-hatch adhesion test, or a scratch test. These tests help determine the strength and durability of the tin coating and ensure it is firmly adhered to the base metal surface.

How is electrolytic tinplate coil used in the packaging industry?

Electrolytic tinplate coil plays a crucial role in the packaging industry as it is widely used for manufacturing various types of packaging materials. These coils are coated with a thin layer of tin through an electrolytic process, which provides excellent corrosion resistance and ensures the preservation of the packaged goods. This tin coating also enhances the appearance of the packaging, making it more visually appealing to consumers. Additionally, electrolytic tinplate coil can be easily formed into different shapes, allowing for the production of cans, containers, bottle caps, and other packaging products. Overall, this material is essential in the packaging industry due to its protective properties, aesthetic appeal, and versatility.

What are the potential factors that can cause tinplate coil to lose its shape or become deformed?

There are several potential factors that can cause tinplate coils to lose their shape or become deformed. These factors include improper handling during storage or transportation, exposure to excessive heat or cold, excessive pressure or weight placed on the coils, inadequate packaging or protection, and manufacturing defects. Additionally, improper storage conditions such as high humidity or exposure to corrosive substances can also contribute to the deformation of tinplate coils.

Can electrolytic tinplate coil be used in the beverage industry?

Yes, electrolytic tinplate coil can be used in the beverage industry. It is commonly used for packaging cans and bottles due to its excellent corrosion resistance, durability, and ability to preserve the flavor and quality of beverages.

Wholesale Electrolytic Tinplate Coil from supplier in Niue

With our expertise in supplying Electrolytic Tinplate Coils, we are able to offer a wide range of products to meet the specific needs of customers in Niue. Whether you require standard or customized sizes, we can provide the right solution for your project.

Our sales team is dedicated to providing excellent customer service and ensuring that you receive competitive pricing for your Electrolytic Tinplate Coil requirements. We understand the importance of timely and efficient delivery, and we work closely with our logistics partners to ensure that your products arrive on schedule.

In addition to sales, we also offer quotations and technical support services. Our team of experts is available to assist you with any questions or concerns you may have regarding the use and application of Electrolytic Tinplate Coils. We can provide guidance on product selection, offer technical specifications, and help troubleshoot any issues that may arise.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have the resources and capabilities to provide comprehensive procurement services for Electrolytic Tinplate Coils in Niue. Our strong network of suppliers and partners enables us to source high-quality products at competitive prices, ensuring that you receive the best value for your investment.

With years of market development experience in Niue, we have built valuable relationships with local customers and gained a deep understanding of the unique requirements and preferences of the market. This allows us to provide valuable insights and expertise to help you make informed decisions for your projects.

Whether you are in need of Electrolytic Tinplate Coils for packaging, canning, or any other application, we are here to support you every step of the way. Contact us today to discuss your requirements and discover how we can assist you in achieving your goals.

Our sales team is dedicated to providing excellent customer service and ensuring that you receive competitive pricing for your Electrolytic Tinplate Coil requirements. We understand the importance of timely and efficient delivery, and we work closely with our logistics partners to ensure that your products arrive on schedule.

In addition to sales, we also offer quotations and technical support services. Our team of experts is available to assist you with any questions or concerns you may have regarding the use and application of Electrolytic Tinplate Coils. We can provide guidance on product selection, offer technical specifications, and help troubleshoot any issues that may arise.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have the resources and capabilities to provide comprehensive procurement services for Electrolytic Tinplate Coils in Niue. Our strong network of suppliers and partners enables us to source high-quality products at competitive prices, ensuring that you receive the best value for your investment.

With years of market development experience in Niue, we have built valuable relationships with local customers and gained a deep understanding of the unique requirements and preferences of the market. This allows us to provide valuable insights and expertise to help you make informed decisions for your projects.

Whether you are in need of Electrolytic Tinplate Coils for packaging, canning, or any other application, we are here to support you every step of the way. Contact us today to discuss your requirements and discover how we can assist you in achieving your goals.