All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the challenges in producing high-strength steel coils for military and defense applications?

Producing high-strength steel coils for military and defense applications involves several challenges. Firstly, ensuring the desired strength and durability of the steel while maintaining other mechanical properties is crucial. This requires precise control over the composition and microstructure of the steel during the manufacturing process. Secondly, the production of such coils often demands tight tolerances and strict quality control measures to meet the stringent standards set by the military. Additionally, there may be specific requirements for the coils, such as resistance to corrosion, impact resistance, and compatibility with other materials used in defense systems. Meeting these specifications while ensuring cost-effectiveness and timely production poses further challenges.

What is the role of edge conditioning in the coil processing for the manufacturing of metal furniture?

Edge conditioning in coil processing for the manufacturing of metal furniture plays a crucial role in achieving high-quality and visually appealing end products. It involves the removal of sharp edges, burrs, and imperfections from the edges of the metal coil, ensuring a smooth and safe surface. This process enhances the overall aesthetic appeal of the furniture by providing clean and consistent edges, while also preventing potential injuries during handling and usage. Additionally, edge conditioning facilitates easier and more precise bending, forming, and joining of metal components, resulting in improved structural integrity and durability of the furniture pieces.

How are steel coils tested for thickness accuracy?

Steel coils are tested for thickness accuracy using a non-destructive testing method called ultrasonic testing. This involves the use of high-frequency sound waves that are transmitted through the steel coil. By measuring the time it takes for the sound waves to bounce back, technicians can accurately determine the thickness of the steel coil.

Wholesale Steel Coils from supplier in Romania

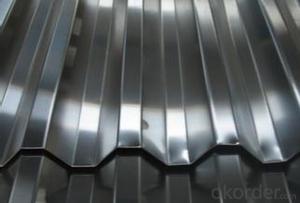

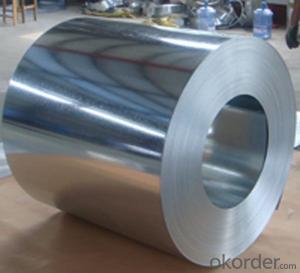

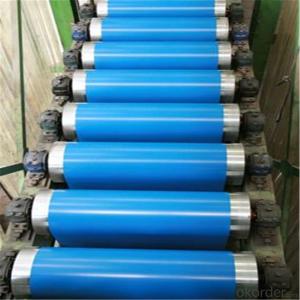

With our commitment to quality and customer satisfaction, we strive to deliver steel coils that meet the highest industry standards. Our wide range of steel coil products includes hot rolled coils, cold rolled coils, galvanized coils, and stainless steel coils, among others.

We understand the unique requirements of the Romanian market and work closely with our customers to provide tailored solutions for their specific needs. Whether you are in the construction, automotive, or manufacturing industry, we have the right steel coil products to support your projects.

In addition to our extensive product range, we also offer value-added services such as cutting, slitting, and packaging to ensure that our customers receive their steel coils in the desired form and size.

Our team of experienced professionals is dedicated to providing excellent customer service. We offer timely sales support, competitive quotations, and technical assistance to help our customers make informed decisions.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the financial strength and resources to ensure a reliable and efficient supply chain. We have established strong partnerships with reputable steel manufacturers, both domestically and internationally, to guarantee the availability of high-quality steel coils at competitive prices.

We are proud to be a leading supplier of steel coils in Romania and look forward to serving your steel coil needs. Contact us today for sales inquiries, quotations, or technical support.

We understand the unique requirements of the Romanian market and work closely with our customers to provide tailored solutions for their specific needs. Whether you are in the construction, automotive, or manufacturing industry, we have the right steel coil products to support your projects.

In addition to our extensive product range, we also offer value-added services such as cutting, slitting, and packaging to ensure that our customers receive their steel coils in the desired form and size.

Our team of experienced professionals is dedicated to providing excellent customer service. We offer timely sales support, competitive quotations, and technical assistance to help our customers make informed decisions.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the financial strength and resources to ensure a reliable and efficient supply chain. We have established strong partnerships with reputable steel manufacturers, both domestically and internationally, to guarantee the availability of high-quality steel coils at competitive prices.

We are proud to be a leading supplier of steel coils in Romania and look forward to serving your steel coil needs. Contact us today for sales inquiries, quotations, or technical support.