All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

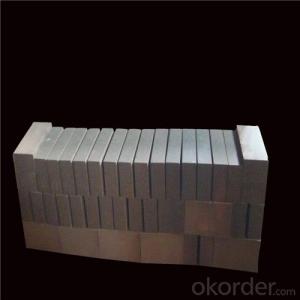

What are the different compositions of refractory bricks?

The different compositions of refractory bricks can vary depending on their specific applications and desired properties. However, common compositions include materials such as alumina (Al2O3), silica (SiO2), magnesia (MgO), zirconia (ZrO2), chromite (FeCr2O4), and carbonaceous materials. These compositions are chosen based on factors like the desired refractoriness, resistance to thermal shock, chemical inertness, and mechanical strength required for a particular application.

Can refractory bricks be used for incinerators?

Yes, refractory bricks can be used for incinerators. Refractory bricks are specifically designed to withstand high temperatures and provide insulation, making them suitable for lining the walls, floors, and roofs of incinerators. Their ability to resist heat and chemical corrosion ensures the longevity and efficiency of the incineration process.

Are refractory bricks resistant to alkali sulfates?

Yes, refractory bricks are generally resistant to alkali sulfates.

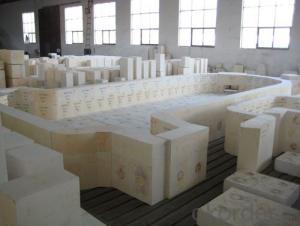

Wholesale Refractory Bricks from supplier in Israel

Whether you are in need of Refractory Bricks for industrial furnaces, kilns, or other high-temperature applications, our team of experts can help you identify the right products for your specific requirements. We work closely with leading manufacturers to ensure the highest quality standards and competitive pricing.

Our sales team is dedicated to providing exceptional customer service, assisting you throughout the entire procurement process. From initial inquiries to order fulfillment and after-sales support, we are committed to meeting your needs and exceeding your expectations.

In addition to sales, we offer comprehensive pricing solutions tailored to your budget and project requirements. Our team will work closely with you to provide competitive pricing options, ensuring that you receive the best value for your investment.

Technical support is another key service we provide. Our team of experienced engineers and technicians can offer guidance and expertise in selecting the most suitable Refractory Bricks for your specific applications. We can assist with product recommendations, installation techniques, and troubleshooting, ensuring optimal performance and longevity of your refractory materials.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This enables us to provide convenient and efficient one-stop procurement services for Refractory Bricks in Israel. We have a strong track record of delivering high-quality products and services, and our presence in the Israeli market allows us to understand the unique needs and challenges of local industries.

Whether you are in construction, steel production, ceramics, or any other industry requiring refractory solutions, we are here to support you. Contact us today to discuss your requirements and let us be your trusted partner for all your Refractory Brick needs in Israel.

Our sales team is dedicated to providing exceptional customer service, assisting you throughout the entire procurement process. From initial inquiries to order fulfillment and after-sales support, we are committed to meeting your needs and exceeding your expectations.

In addition to sales, we offer comprehensive pricing solutions tailored to your budget and project requirements. Our team will work closely with you to provide competitive pricing options, ensuring that you receive the best value for your investment.

Technical support is another key service we provide. Our team of experienced engineers and technicians can offer guidance and expertise in selecting the most suitable Refractory Bricks for your specific applications. We can assist with product recommendations, installation techniques, and troubleshooting, ensuring optimal performance and longevity of your refractory materials.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This enables us to provide convenient and efficient one-stop procurement services for Refractory Bricks in Israel. We have a strong track record of delivering high-quality products and services, and our presence in the Israeli market allows us to understand the unique needs and challenges of local industries.

Whether you are in construction, steel production, ceramics, or any other industry requiring refractory solutions, we are here to support you. Contact us today to discuss your requirements and let us be your trusted partner for all your Refractory Brick needs in Israel.

Hot Search

- Monolithic Refractories in Nepal

- Ceramic Fiber Products in Sri Lanka

- Refractory Bricks in Palau

- Raw Materials For Refractory in Timor Leste

- Raw Materials For Refractory in Uruguay

- Monolithic Refractories in Fiji

- Ceramic Fiber Products in Swaziland

- Ceramic Fiber Products in Kiribati

- Monolithic Refractories in Serbia

- Raw Materials For Refractory in Jamaica