Customized Color Aluminum Coated Coils for Different Usages

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

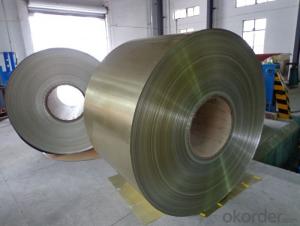

1. Structure of Plain Aluminium Coils for Different Usages Our aluminum Coils are widely used in solar energy curtain wall. It integrates a photo-voltaic system. Photovoltaic panels are usually installed on the glass of curtain wall to generate electricity from solar energy. Plain Aluminium Coils for Different Usages can meet the highest standards in its own mill while save the cost. Our strong quality control term bring you the most-qualified products. And with state-of-the-art equipment, and the state owned company background, we have to say, you will understand why there are so many company choose CNBM to be their supplier. CNBM aluminum complying with YS/T 429-2000(Chinese Industry Standard),GB/T 3880,EN485,ASTM B209. 2.Main Features of Plain Aluminium Coils for Different Usages •High intensity •Easy to be processed and shaped •Weather resistance •Anti-pollution & environment protection 3. Plain Aluminium Coils for Different Usages Images 4.Specification of Plain Aluminium Coils for Different Usages Alloy: AA1×××; AA3×××; AA5×××; AA8××× Temper: H14; H16; H18; H22; H24; H26; H32; O; F Thickness: 0.2mm-100mm Width: 30mm-1700mm Standard: GB/T 3880-2006 5.FAQ A.What about inspections to guarantee quality? For each order for Aluminum Coils, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods. With requirement of customers, we also can arrange the third party inspection. B.What about delivery? We will put order for Aluminum Coils in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity. C.What is the MOQ? 5 tons for each size. D. Where have you exported aluminium Coils? We have exported aluminum Coils to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: This question asks for guidelines on how to properly store aluminum coils to ensure their safety and longevity.

- <p>To store aluminum coils, follow these steps: Ensure the storage area is clean, dry, and free from dust and moisture. Keep the coils on wooden pallets or racks to avoid direct contact with the ground. Stack the coils with the same size and type to prevent damage. Use protective wrapping or covers to prevent scratches and dirt accumulation. Maintain proper ventilation to prevent condensation. Store coils away from corrosive materials and chemicals. Regularly inspect the coils for any signs of damage or corrosion. By following these guidelines, you can maintain the quality and integrity of aluminum coils during storage.</p>

- Q: How to measure the thickness of aluminum coil at real time? In what areas can the sensor be used?

- It can be used in non-contact measurement of displacement, three-dimensional size, thickness, object deformation and vibration.

- Q: How do aluminum coils contribute to the sound insulation of buildings?

- Aluminum coils contribute to the sound insulation of buildings through their unique properties and applications. Aluminum is a lightweight and flexible material that can be easily formed into coils, making it an ideal choice for sound insulation purposes. One of the main ways aluminum coils contribute to sound insulation is by acting as a barrier to prevent the transmission of sound waves. When installed in walls, ceilings, or floors, these coils create an additional layer that helps to block and absorb sound energy. Aluminum has a high density and rigidity, which allows it to effectively reflect and absorb sound waves, reducing their intensity as they pass through the building structure. Moreover, aluminum coils can be combined with other soundproofing materials, such as foam or fiberglass, to enhance their sound absorption capabilities. These combinations provide a more comprehensive sound insulation system, as the different materials work together to trap and dampen sound waves. Another advantage of aluminum coils is their resistance to moisture and corrosion, which makes them suitable for both indoor and outdoor applications. This durability ensures that the sound insulation provided by aluminum coils remains effective over time, even in harsh environments. Additionally, aluminum coils are easy to install and maintain, making them a cost-effective solution for sound insulation in buildings. Their lightweight nature allows for easy transportation and handling, while their flexibility enables them to be installed in various positions and configurations. In summary, aluminum coils contribute to the sound insulation of buildings by acting as a barrier to sound transmission, reflecting and absorbing sound waves, and providing durability and versatility. Their combination with other soundproofing materials further enhances their effectiveness. With their lightweight and flexible properties, aluminum coils offer a practical and cost-effective solution to improve the acoustic performance of buildings.

- Q: Are aluminum coils suitable for food storage containers?

- Yes, aluminum coils are suitable for food storage containers. Aluminum is a non-toxic and non-reactive metal that is safe for storing food. It is lightweight, durable, and has excellent temperature retention properties, making it a popular choice for food storage containers.

- Q: Is it possible to utilize aluminum coils in the process of water treatment?

- <p>Yes, aluminum coils can be used for water treatment. They are often used in processes such as coagulation and flocculation, where aluminum salts are added to the water to help remove suspended particles and impurities. The aluminum ions react with the particles in the water to form larger, heavier particles that can be more easily settled or filtered out. Additionally, aluminum coils can be part of an electrode system in electrocoagulation processes, where an electric current is used to treat water by generating aluminum ions at the anode. This method is effective for removing various contaminants, including heavy metals, bacteria, and organic compounds.</p>

- Q: What are the different surface treatment options available for aluminum coils?

- There are several surface treatment options available for aluminum coils, each serving different purposes and providing unique benefits. Some of the commonly used surface treatment options include: 1. Anodizing: Anodizing is an electrochemical process that creates a protective oxide layer on the surface of the aluminum coil. This treatment enhances corrosion resistance, improves durability, and allows for coloring options. 2. Painting: Painting the aluminum coil provides an aesthetic finish while also protecting it from corrosion. The coil can be coated with various types of paints, such as polyester, epoxy, or polyurethane, depending on the desired appearance and level of protection required. 3. Powder Coating: Powder coating involves applying a dry powder to the aluminum coil's surface and then curing it with heat. This process creates a durable and attractive finish that is resistant to chipping, scratching, and fading. Powder coating also offers a wide range of color options and can be used in various applications. 4. Brushing: Brushing the aluminum coil creates a brushed or satin finish with visible linear patterns. This treatment is commonly used for decorative purposes, giving the coil a unique and visually appealing appearance. 5. Laminating: Laminating involves bonding a protective layer, such as a PVC film or a polyester film, onto the surface of the aluminum coil. This treatment provides additional protection against scratches, abrasion, and UV radiation while also offering customization options. 6. Chemical Conversion Coating: Chemical conversion coating, also known as chromate conversion coating, involves applying a thin layer of chromate onto the aluminum coil's surface. This treatment enhances corrosion resistance, improves paint adhesion, and provides a base for subsequent painting or powder coating. It is important to choose the appropriate surface treatment option based on the specific requirements of the application, such as durability, corrosion resistance, aesthetics, and cost-effectiveness. Consulting with experts in the field can help determine the most suitable treatment option for aluminum coils.

- Q: This question asks for methods to protect aluminum coils from damage during storage and transportation.

- <p>To prevent damage to your aluminum coil during storage or transportation, follow these guidelines: Store the coils in a dry and clean environment to prevent moisture and dirt accumulation. Ensure that the storage area is well-ventilated to avoid condensation. Use appropriate padding or separators between coils to prevent scratching or denting. Handle the coils with care, using proper lifting equipment to avoid dropping or mishandling. Secure the coils during transportation to prevent movement that could lead to damage. Keep the coils away from corrosive substances and extreme temperatures. Regularly inspect the coils for any signs of damage and address any issues promptly.</p>

- Q: Automotive aluminum coil, using GB H22, what brand, what are the main ingredients?

- 5754-H22 aluminum sheet has the characteristics of medium strength, good corrosion resistance, weldability and easy processing. It is a typical alloy in Al-Mg (mg Al alloy) alloy. In the corresponding foreign brands for AlMg3, 5754 different heat treatment is the automobile manufacturing industry (car door, mould, seals), main materials used for canning industry

- Q: Can aluminum coils be used in food processing applications?

- Yes, aluminum coils can be used in food processing applications. Aluminum is a widely used material in the food industry due to its excellent thermal conductivity, corrosion resistance, and lightweight properties. Aluminum coils are commonly used in food processing equipment such as refrigerators, ovens, and food storage units to ensure proper temperature control and hygiene during food processing.

- Q: Is it possible to utilize an aluminum coil as a light source?

- <p>Aluminum coil itself cannot be used as a light source. Aluminum is a good conductor of electricity but does not emit light when electrified like certain materials can. To create light, materials like tungsten in incandescent bulbs or phosphors in fluorescent lights are used. Aluminum coils can, however, be used in conjunction with other components in lighting fixtures, such as in heat sinks to dissipate heat from LEDs, but they do not produce light directly.</p>

Send your message to us

Customized Color Aluminum Coated Coils for Different Usages

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords