Customized Embossed Aluminum Coil for Decoration and Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Aluminium Strips Use for Decoration and Building

l Product Specification

Product | Aluminium Strip | ||

Alloy | 1100, 1145, 1050, 1060, 1070, 3003, 3013, 3005, 3A21, 4343, 4045, 5052, 5082, 5083, 5086, 6061, 8011etc. | Temper | H12. H14. H16. H18. H22. H24. H26. H32. H34. H36. H38. O etc. |

Thickness | 0.06mm-6.0mm | Width | 5mm-900mm |

Coil Weight | At clients' request | ||

Package | Eye to sky and eye to wall both available | ||

Inner core Diameter | 76mm, 505mm, paper core or steel coil is availbale, also we can make no core inside | ||

Applications | Gutter, constructions, decorations, air conditioning and radiators etc. | ||

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirement

Delivery detail: about 25 days from received oiginal L/C or advance payment

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

l CNBM World Wide

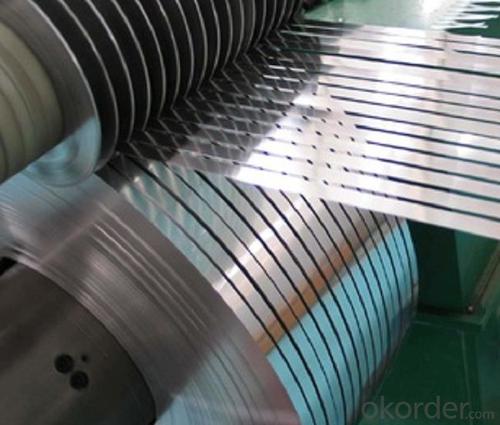

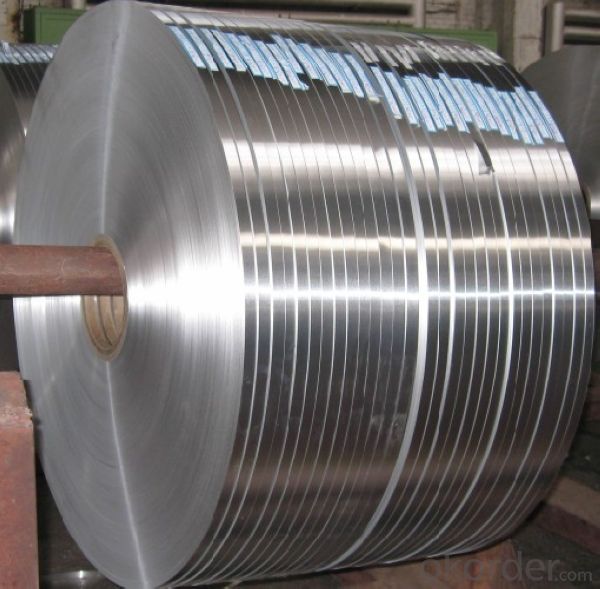

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q: What are the different thickness options for aluminum coils?

- The thickness options for aluminum coils can vary, but common thicknesses range from 0.019 inches to 0.125 inches.

- Q: Can aluminum coils be used in water treatment plants?

- Aluminum coils have a wide range of applications in water treatment plants due to their corrosion resistance and efficiency in heat transfer. They are commonly used in heat exchangers and condensers for optimal heat transfer. In water treatment plants, aluminum coils serve various purposes. For instance, they are utilized in cooling towers to effectively remove heat from water by circulating it over the coils. This process facilitates the transfer of heat from the water to the surrounding air, resulting in the cooling of the water. Moreover, aluminum coils are also employed in the construction of evaporators, which aid in the evaporation of water during the treatment process. These coils are designed to have a large surface area, maximizing contact between the water and the aluminum surface to enhance evaporation efficiency. Additionally, aluminum coils play a crucial role in air handling units (AHUs) within water treatment plants. AHUs help regulate temperature, humidity, and air quality in the facility. The aluminum coils in AHUs contribute to the overall efficiency of the system by cooling or heating the air passing through them. However, it is important to consider the compatibility of aluminum with the specific water being treated. Certain water compositions, such as those with low pH or high levels of certain chemicals, can cause corrosion or chemical reactions that may affect the performance and durability of aluminum coils. Therefore, it is essential to assess the water composition and seek guidance from experts or manufacturers to ensure the suitability of aluminum coils for a particular water treatment application.

- Q: Are aluminum coils suitable for signage applications?

- Yes, aluminum coils are suitable for signage applications. Aluminum is a highly versatile material that offers several advantages for signage purposes. Firstly, aluminum coils are lightweight, making them easy to handle and install. This is particularly beneficial for large outdoor signs or banners that need to be mounted or hung. Additionally, aluminum is highly resistant to corrosion, ensuring that the signage will remain in good condition even in harsh weather conditions. This durability also makes aluminum coils suitable for long-term outdoor use, as they can withstand exposure to UV rays, moisture, and temperature changes without deteriorating. Furthermore, aluminum coils can be easily fabricated and shaped to create various sign designs, including flat panels, channel letters, and dimensional signage. They can be painted or coated with different finishes to achieve the desired aesthetic appearance, making them versatile for branding and marketing purposes. Another advantage of using aluminum coils for signage applications is their recyclability. Aluminum is a sustainable material that can be recycled repeatedly without losing its quality. This makes it an environmentally-friendly choice for businesses that prioritize sustainability and want to reduce their carbon footprint. In summary, aluminum coils are a suitable choice for signage applications due to their lightweight nature, corrosion resistance, durability, versatility in design, and recyclability.

- Q: What are the common handling and storage practices for aluminum coils?

- The common handling and storage practices for aluminum coils include wearing protective gloves and eyewear when handling the coils to prevent injuries. It is necessary to handle the coils carefully and avoid dropping or dragging them to prevent damage. Additionally, coils should be stored in a dry and well-ventilated area to avoid moisture buildup and corrosion. They should be stacked on a flat and sturdy surface, with proper support and spacing between each coil to prevent deformation. Regular inspections and maintenance should be conducted to ensure the coils are stored and handled correctly.

- Q: Are aluminum coils resistant to oil and grease?

- Aluminum coils typically possess resistance against oil and grease. They exhibit a natural ability to resist corrosion and are not easily influenced by most solvents, including oil and grease. This characteristic renders aluminum coils a suitable option for diverse applications that involve potential contact with oils or greases, such as the automotive and HVAC sectors. Nevertheless, it is crucial to acknowledge that extended exposure to particular aggressive chemicals or high concentrations of oil or grease may gradually result in damage or deterioration of the aluminum coils. Consequently, it is advisable to diligently clean and maintain the coils to guarantee their optimal functioning and durability.

- Q: What are the different alloy compositions used in aluminum coils?

- Aluminum coils utilize various alloy compositions, each with distinct properties and applications. Let's explore some of the commonly employed compositions: 1. The 1000 series alloys are nearly pure aluminum, boasting exceptional ductility and corrosion resistance, with a minimum aluminum content of 99%. These alloys find utility in scenarios demanding formability and efficient electrical conductivity, such as electrical wiring and packaging. 2. Manganese is present in small quantities within the 3000 series alloys, rendering them sturdier and more corrosion-resistant than their 1000 series counterparts. Cooking utensils, chemical equipment, and decorative trim are among the applications where these alloys are frequently employed. 3. Magnesium serves as the primary alloying element in the 5000 series alloys, significantly enhancing their strength and hardness. Renowned for their impressive resistance to corrosion, these alloys are commonly utilized in marine environments, as well as the automotive and aerospace industries. 4. The 6000 series alloys are combined with magnesium and silicon, leading to improved strength, heat treatability, and weldability. Architectural and structural components, transportation, and electrical conductors often rely on these alloys. 5. Zinc is the primary alloying element in the 7000 series alloys, providing them with remarkable strength and toughness. These alloys are frequently employed in high-stress environments, including aircraft structural components and sporting equipment. It is crucial to acknowledge that numerous alloy compositions are employed in aluminum coils, each tailored to specific requirements and applications. The choice of alloy composition hinges on factors such as desired strength, corrosion resistance, formability, and cost considerations.

- Q: Can aluminum coils be used in corrosive environments?

- Yes, aluminum coils can be used in corrosive environments. Aluminum is known for its excellent corrosion resistance due to the formation of a protective oxide layer on its surface. This oxide layer acts as a barrier, preventing further corrosion from occurring. Additionally, aluminum coils are often coated with a protective layer or treated with special coatings to enhance their resistance to corrosive environments further. However, it is essential to consider the specific corrosive environment and consult with experts to ensure that the chosen aluminum coil and protective measures are suitable for the specific conditions in which they will be used.

- Q: can you use the Brasso Aluminum cleaner on aluminum wheels? i have a set of mickey thompson classic II wheels and i want to polish them up. they have water spots that are almost impossible to clean. how can i shine them up to make them almost like chrome wheels? i heard brasso works great but then i heard it damages the wheels?

- There are many products you can use to polish aluminum wheels, Brasso aluminum polish being one of them. It will take a TON of elbow grease and patience to get a really shiny surface, and it will only become chrome-like if the wheels' surface is already perfectly smooth. The commercially available polishes should remove water spots and will tidy up a surface that is polished already, but will not make a non-polished aluminum surface chrome-like. I've used Mother's and Auto-sol, both with good success. Again, it takes a LOT of work. Follow the instructions carefully. Once you get that shiny surface, it will take periodic regular polishing to maintain. If you are starting with a much more weathered surface, you'll need to go the sanding, wet-sanding, rubbing compound, jeweller's rouge, then metal polish route. A ton of work, but doable. Look up how to polish aluminum on Google.

- Q: Can aluminum coils be recycled multiple times?

- Aluminum coils possess the remarkable ability to be recycled numerous times. This is due to the fact that aluminum is an exceptionally recyclable substance, and its quality remains unaltered throughout the recycling process. As a result, aluminum coils can be melted and reshaped into fresh coils on multiple occasions, without experiencing any deterioration in their performance or characteristics. The act of recycling aluminum not only aids in the preservation of natural resources, but it also conserves a significant amount of energy compared to the production of new aluminum using raw materials. Consequently, opting for aluminum coils is a sustainable and eco-friendly decision, as they can be recycled multiple times.

- Q: Can aluminum coils be utilized in the process of welding?

- <p>Yes, aluminum coils can be used for welding work. They are commonly used as filler material in processes like MIG (Metal Inert Gas) welding. Aluminum welding requires specific techniques and equipment due to its high thermal conductivity and the need for shielding from oxidation. The aluminum coils must be of good quality and compatible with the welding process to ensure a strong and durable weld. Proper selection of welding parameters, such as amperage and voltage, is crucial for successful aluminum welding.</p>

Send your message to us

Customized Embossed Aluminum Coil for Decoration and Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords