Buy Coated Aluminum Coil

Buy Coated Aluminum Coil Related Searches

Buy Aluminum Coil Color Coated Aluminum Coil Colored Aluminum Coil Coated Aluminum Coil Suppliers Copper Colored Aluminum Coil Polished Aluminum Coil Coil Coated Aluminum Coated Aluminum Coil Pe China Color Coated Aluminum Coil Anodized Aluminum Coil Vinyl Coated Aluminum Coil Coil Coating Aluminum Powder Coated Aluminum Coil Pvc Coated Aluminum Coil Copper Aluminum Coil Prepainted Aluminum Coil Textured Aluminum Coil Coating Aluminum Coil Pe Colored Aluminum Trim Coil Colored Aluminum Coil Stock Best Aluminum Coil Coil Aluminum Aluminum Coil Wholesale Wooden Texture Coated Aluminum Coil Aluminum Copper Coil Aluminum Ac Coil Wholesale Aluminum Coil Aluminum Coil Price Brushed Aluminum Coil Custom Rolled Aluminum CoilBuy Coated Aluminum Coil Supplier & Manufacturer from China

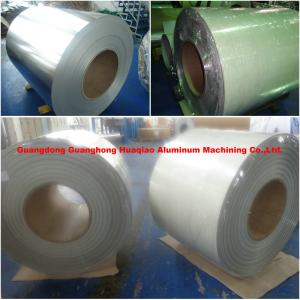

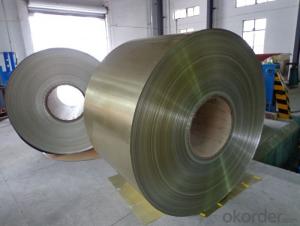

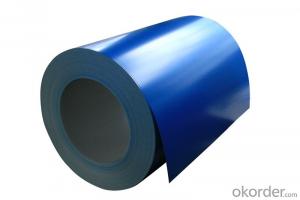

Buy Coated Aluminum Coil is a type of metal product that features a protective and decorative layer applied to its surface. This coating not only enhances the aesthetic appeal of the aluminum but also provides corrosion resistance and durability. The coated aluminum coil is widely used in various industries, including construction, automotive, and consumer electronics, where it is utilized for applications such as roofing, siding, and exterior panels.Coated aluminum coil offers a versatile and efficient solution for numerous applications, making it a popular choice for both commercial and residential projects. Its ability to withstand harsh weather conditions and maintain its appearance over time has made it a preferred material for architectural and design purposes. Okorder.com, as a wholesale supplier, offers a vast inventory of Buy Coated Aluminum Coil to cater to the diverse needs of customers across different sectors. With a commitment to quality and competitive pricing, Okorder.com ensures that clients can access the coated aluminum coil they require for their specific projects.

Hot Products