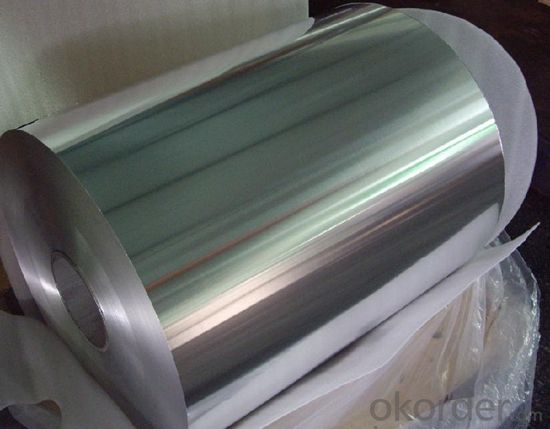

Aluminum Prepainted Aluminum Coil for Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Grade:

5000 Series

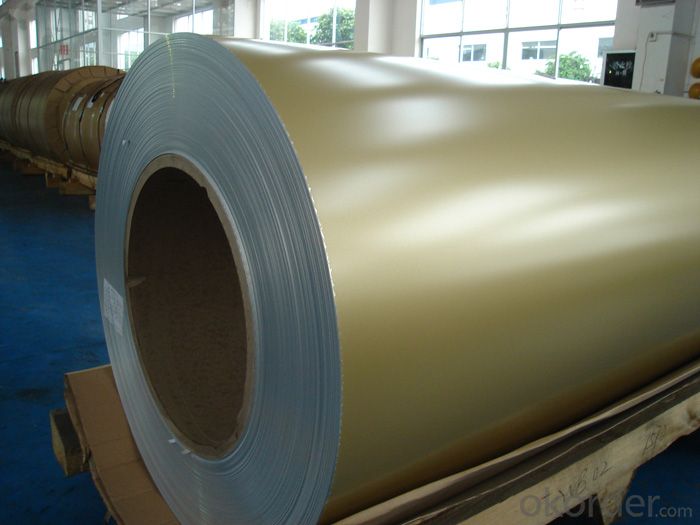

Surface Treatment:

Color Coated

Shape:

Rectangular

Temper:

T3-T8

Application:

Decorations

1. Grade

| Series: | 1100 etc. |

| Series: | 3003 3004 3005 etc. |

| Series: | 5006, 5052 |

| Series: | 8011 etc. |

2. Thickness

| Plate Thickness | 0.1mm, 0.12mm,0.15mm,0.20mm,0.25mm,0.28mm,0.3mm,0.35mm,0.38mm, 0.4mm,0.5mm, 0.53mm, 0.58mm,0.68mm,0.7omm,0.73mm,0.75mm, 0.90mm, 1mm, 1.2mm |

| Coil Thickness | 0.1mm, 0.12mm,0.15mm,0.20mm,0.25mm,0.28mm,0.3mm,0.35mm,0.38mm, 0.4mm,0.5mm, 0.53mm, 0.58mm,0.68mm,0.7omm,0.73mm,0.75mm, 0.90mm, 1mm, 1.2mm |

3. Colored aluminum foil Technical Data Of colorful coated aluminum coil :

| Item | Test Item | Standard | National Standard | Test Result |

| 1 | Color Difference | ECCA T3 | Delter E≤2.0 | Delter E≤1.0 |

| 2 | Gloss Difference | ECCA T2 | ≤10 | ≤5 |

| 3 | Coating Thickness | ECCA T1 | Two coating Min 23 mircron | ≥25 micron |

| Three coating Min 30 micron | ≥34 micron | |||

| 4 | Pencil Hardness | ASTM D3363 | ≥HB | HB |

| 5 | T-Bend | ASTM D4145 | ≤2T | ≤2T |

| 6 | Adhesion | ASTM D3359 | Grade 0 | Grade 0 |

| 7 | Impact | ASTM D2794 | ≤50kg.cm | ≤50kg.cm |

| 8 | Boiling Water Resistance | GB/T17748 | 2hr no change | 4hr no change |

| 9 | Slovent Resistance | ASTM D2248 | 200 times paint remaining | 500 times paint remaining |

| 10 | Acidity Resistance | ASTM D1308 | 5% HCL 24hrs no change | no change |

| 11 | Alkali Resistance | ASTM D1308 | 5% NAOH 24hrs Delter E≤2.0 | no change |

| 12 | Nitric Acid Resistance | AAMA620 | Delter E<5.0 | Delter E<5.0 |

| 13 | Oil Resistance | ASTM D1308 | 20# oil 24hrs no change | no change |

| 14 | Salt Spray Resistance | ASTM B117 | 4000hrs≤Grade 1 | no change |

| 15 | Abrasion Resistance | ASTM D968 | ≥5L/Micron | ≥5L/Micron |

| 16 | Contamination Resistance | GB/T9780 | ≤5% | <5% |

| 17 | Color Resistance | GB/T16259 | 4000hrs Delter E≤4.0 | 4000hrs Delter E≤3.0 |

| 18 | Gloss Losing Level | 4000hrs Delter E≤Grade 2 | 4000hrs Delter E≤Grade 2 | |

| 19 | Chalking | 4000hrs no change | 4000hrs no change |

- Q: This question asks about the typical issues that arise due to the corrosion of aluminum.

- <p>Common problems with aluminum corrosion include loss of structural integrity, which can compromise the safety and performance of aluminum components. Corrosion can lead to a decrease in mechanical strength, increased brittleness, and a reduction in the electrical and thermal conductivity of aluminum. Additionally, aesthetic issues such as discoloration and pitting can occur, affecting the appearance of aluminum surfaces. Environmental factors and improper handling can accelerate corrosion, leading to costly repairs or replacements.</p>

- Q: This question asks for methods to determine the presence of aluminum in an alloy.

- <p>To determine if an alloy contains aluminum, one can use various analytical techniques. A common method is spectroscopy, which can identify the presence of specific elements by analyzing the wavelengths of light absorbed or emitted. Another approach is the use of a spark test, where a sample is struck against a grinding wheel to produce sparks; the color and pattern of these sparks can indicate the presence of aluminum. Chemical tests, such as the reaction with sodium hydroxide, can also be used, as aluminum reacts with NaOH to produce hydrogen gas. Lastly, X-ray fluorescence (XRF) is a non-destructive technique that can accurately determine the elemental composition of an alloy, including aluminum content.</p>

- Q: Explain how the production process of recycled aluminum differs from that of new aluminum, focusing on energy consumption and environmental impact.

- <p>The production process for recycled aluminum is significantly less energy-intensive compared to the production of new aluminum. Producing new aluminum from bauxite ore requires high temperatures and substantial energy, often from fossil fuels, to smelt the ore and extract the metal. This process emits greenhouse gases and consumes large amounts of electricity. In contrast, recycling aluminum involves melting down existing aluminum products, which requires only about 5% of the energy needed to produce new aluminum. This process is more environmentally friendly, as it reduces energy consumption, lowers greenhouse gas emissions, and conserves natural resources by decreasing the need for raw materials.</p>

- Q: This question asks about the amount of energy needed to produce aluminum.

- <p>The energy required for the production of aluminum is substantial. Producing one ton of aluminum typically requires around 15-25 kilowatt-hours of electricity, largely due to the process of electrolysis, which is used to extract aluminum from its ore, bauxite. This high energy consumption is a significant factor in aluminum production costs and environmental impact. The energy required can vary based on the efficiency of the smelting process and the source of electricity used.</p>

- Q: What are some environmentally friendly options that can replace aluminum in various applications?

- <p>Sustainable alternatives to aluminum include biodegradable materials like bamboo and hemp, which can be used in construction and packaging. Stainless steel is a recyclable metal that can replace aluminum in many applications due to its durability and strength. Recycled aluminum itself is a sustainable option as it requires less energy to produce than new aluminum. Additionally, magnesium and titanium are lightweight metals that can be used in place of aluminum in certain industries. It's important to consider the specific application when choosing an alternative, as each material has its own set of properties and environmental impacts.</p>

- Q: Does aluminum have the ability to corrode or deteriorate over time?

- <p>Yes, aluminum can corrode, but it typically forms a protective oxide layer on its surface when exposed to air, which prevents further corrosion. This layer of aluminum oxide is very thin but strong and stable, making aluminum highly resistant to corrosion. However, under certain conditions such as exposure to certain chemicals or in the absence of oxygen, aluminum can still corrode. Corrosion can also occur if the protective layer is damaged or compromised.</p>

- Q: Angell doors and windows as a door brand, compared to other aluminum alloy doors and windows what are the advantages?

- Patterns, products, services have advantages, you can go to their official website to see.

- Q: This question asks for an overview of the environmental concerns associated with the manufacturing process of aluminum.

- <p>The production of aluminum is associated with several environmental issues. One major concern is the high energy consumption required for the smelting process, which contributes to greenhouse gas emissions. The process also generates significant amounts of waste, including red mud, a hazardous byproduct that can contaminate soil and water if not properly managed. Additionally, deforestation and habitat destruction occur due to the mining of bauxite, the primary ore of aluminum. Air pollution is another issue, as the production process releases particulates and other pollutants into the atmosphere. Lastly, the depletion of non-renewable resources, such as fossil fuels used in the smelting process, is a long-term environmental concern related to aluminum production.</p>

- Q: This question asks about the various applications and purposes of aluminum in different industries and everyday life.

- <p>Aluminum is widely used due to its lightweight, corrosion resistance, and high thermal and electrical conductivity. It's extensively used in the transportation industry for manufacturing vehicles, airplanes, and ships. In construction, it's used for window frames, roofing, and structural components. Aluminum is also prevalent in packaging, particularly for food and beverages, and in electrical components like wiring and capacitors. Additionally, it's used in everyday items such as cans, foil, and cookware, and in industrial machinery and tools. Its versatility and recyclability make it a valuable material across many sectors.</p>

- Q: This question asks whether the energy consumption for producing recycled aluminum is lower compared to the production of new aluminum.

- <p>Yes, producing recycled aluminum requires significantly less energy than producing new aluminum. Recycling aluminum uses only about 5% of the energy needed to produce primary aluminum from bauxite ore. This is because recycling involves melting and recasting the metal, which is a much less energy-intensive process than mining, refining, and smelting new aluminum. As a result, recycling aluminum helps conserve energy and reduces greenhouse gas emissions associated with aluminum production.</p>

Send your message to us

Aluminum Prepainted Aluminum Coil for Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords