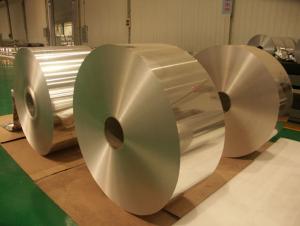

Aluminium Foilstock for Lamination

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000 MT / Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Aluminium Foil Stock for Lamination Foil

Alloy: 8079 / 8011 / 1235

Temper: H14 / H16 / H24 / H26

Specifications of Aluminium Foil Stock for Lamination Foil

Thickness & Tolerance: 0.28 mm - 0.3 mm (+/-0.01%)

Width & Tolerance: 1000 - 2020 mm (+/-1 mm)

Core I.D.: 405/505/508 mm

Surface Quality: Good appearance with no-crack and well distribute grain

Build Up: Tight slit edges free from cracks, layer to layer shift not more then 2 mm

Flatness: Mill flatnesscoil having slight edge waviness rather than center buckles shall be acceptable

Rolling Performance: Re-rollable to the final desired gauges

Standard: GB/T3198 / ASTM-B209

Usage/Application of Aluminium Foil Stock for Lamination Foil

To produce aluminium foil for lamination foil application

Packaging & Delivery of Aluminium Foil Stock for Lamination Foil

- Q: This question asks for typical applications of aluminum foil in everyday life.

- <p>Aluminum foil is commonly used for food storage and preservation, as it can be wrapped around food to keep it fresh. It's also widely used in cooking, particularly for baking and roasting, to prevent food from sticking to pans or to seal in moisture and flavor. Beyond culinary uses, aluminum foil is employed in arts and crafts for creating 3D structures or as a reflective surface. It's also used in insulation, as a barrier in construction, and for packing and wrapping items to protect them during shipping. Additionally, aluminum foil is utilized in various industrial processes due to its heat resistance and malleability.</p>

- Q: This question asks about the energy consumption involved in the manufacturing process of an aluminum can.

- <p>The energy required to process and produce an aluminum can varies based on factors like production scale and technology used. On average, it takes about 70-90 kilowatt-hours (kWh) of energy to produce a single aluminum can. This includes the energy for mining bauxite, refining it into alumina, smelting it into aluminum, and finally, manufacturing the can. The energy consumption is significantly lower compared to producing cans from other materials like steel or plastic, which makes aluminum cans more energy-efficient.</p>

- Q: This question asks about the chemical reaction between aluminum and water.

- <p>Aluminum does not react with water under normal conditions. However, when aluminum is heated, it can react with steam to form aluminum oxide and hydrogen gas. The reaction is exothermic and can be represented by the following equation: 2Al + 3H2O 鈫?Al2O3 + 3H2. This reaction is utilized in some industrial processes, but it is not a common occurrence in everyday settings. At room temperature, aluminum is protected by a thin layer of aluminum oxide that forms on its surface, which prevents further reaction with water.</p>

- Q: What other applications can aluminum be utilized for in the manufacturing industry besides common uses?

- <p>Aluminum has a wide range of alternative uses in manufacturing due to its lightweight, corrosion resistance, and strength. It is used in the automotive industry for car parts to reduce weight and improve fuel efficiency. In aerospace, aluminum is crucial for aircraft construction due to its strength-to-weight ratio. It's also used in the construction of buildings for window frames, roofing, and facades. In the packaging industry, aluminum is used for food and beverage cans, as well as pharmaceutical blister packs. Additionally, aluminum is utilized in electrical components like wiring and transformers due to its excellent conductivity. It's also found in various consumer goods, such as bicycles, sports equipment, and electronic devices.</p>

- Q: This question asks about the safe usage of aluminum in everyday life.

- <p>Aluminum is widely used in daily life due to its lightweight and corrosion-resistant properties. To use aluminum safely, ensure that aluminum cookware is not used for acidic foods as it may leach aluminum into the food. Avoid storing acidic beverages like soda in aluminum cans for extended periods. Use aluminum foil in moderation, especially when cooking at high temperatures, as it can release aluminum into food. Always wash aluminum utensils thoroughly before and after use. For aluminum cans, recycle them to reduce environmental impact and avoid ingestion of aluminum particles from damaged cans.</p>

- Q: Explain the economic and job market implications of using aluminum.

- <p>The use of aluminum has significant impacts on the economy and job market. It is a key material in various industries, including construction, automotive, aerospace, and consumer goods, which drives demand and economic growth. Aluminum production and processing create jobs directly in mining, refining, and manufacturing sectors, and indirectly in related services and supply chains. Additionally, its lightweight and corrosion-resistant properties make it valuable for energy-efficient transportation, contributing to environmental sustainability and opening new job opportunities in green technologies. However, it also presents challenges such as the need for energy-intensive production processes and the management of waste, which require innovative solutions and can lead to job creation in recycling and environmental management.</p>

- Q: Is it safe and effective to use aluminum foil for wrapping food items in a refrigerator or freezer?

- <p>Yes, you can use aluminum foil to wrap food in a refrigerator or freezer. Aluminum foil is a good insulator and can help keep food fresh by preventing freezer burn and moisture loss. It also protects food from absorbing odors. However, it's important to ensure the foil is tightly wrapped around the food to maintain its effectiveness. Additionally, avoid using aluminum foil with acidic foods as it can react with them, potentially causing a metallic taste.</p>

- Q: This question seeks to understand the safety standards that aluminum products must adhere to, ensuring they are safe for use and do not pose health or environmental risks.

- <p>Safety standards for aluminum products vary by region and application but generally focus on ensuring the products are safe for their intended use and do not pose health or environmental risks. Standards often cover material composition, manufacturing processes, and finished product testing. For example, the American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO) provide standards for aluminum alloys and their applications. Additionally, the Food and Drug Administration (FDA) has specific guidelines for aluminum used in food contact materials to prevent contamination. Compliance with these standards is crucial for manufacturers to maintain product safety and consumer trust.</p>

- Q: This question asks for examples of alloys that include aluminum as one of their components.

- <p>Aluminum is a versatile metal that forms many alloys, enhancing properties like strength, corrosion resistance, and electrical conductivity. Some common aluminum alloys include: 1. 6061, used in aircraft structures and automotive parts due to its good mechanical properties and machinability. 2. 2024, known as 'Alclad', is strong and used in aircraft structures. 3. 7075, one of the strongest aluminum alloys, used in aerospace and military applications. 4. 3003, used for cooking utensils and chemical equipment due to its good corrosion resistance. 5. 5052, used in marine applications and food processing equipment for its excellent corrosion resistance. These alloys are widely used in various industries due to their unique properties.</p>

- Q: What are the various electronic components that utilize aluminum as a primary material?

- <p>Aluminum is used in several types of electronic components due to its good thermal conductivity, lightweight, and corrosion resistance. Some of the common components include: 1. Capacitors: Aluminum electrolytic capacitors are widely used for their high capacitance and low cost. 2. Heat sinks: Aluminum is a popular choice for heat sinks due to its ability to dissipate heat efficiently. 3. Semiconductors: Aluminum is used in semiconductor manufacturing, particularly for interconnects and as a barrier layer. 4. Conductive adhesives: Aluminum-filled adhesives are used for bonding components in electronics. 5. Wires and cables: Aluminum wire is used in some applications due to its lower weight compared to copper. 6. Reflectors: Aluminum is used in light reflectors for its reflective properties. 7. Housings and enclosures: Aluminum is used in the construction of electronic device casings for its strength and lightweight properties.</p>

Send your message to us

Aluminium Foilstock for Lamination

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000 MT / Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords