Aluminium Modelling Mesh

Aluminium Modelling Mesh Related Searches

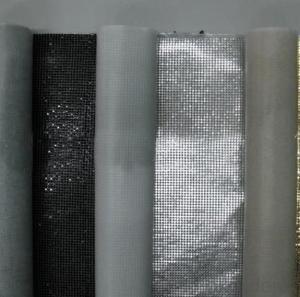

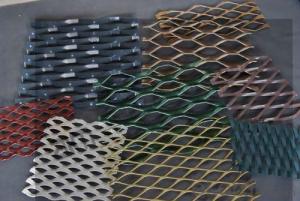

Aluminum Grate Mesh Black Aluminum Mesh Expanded Aluminum Foil Mesh Aluminium Coating Aluminium Mast Working Platform Aluminum Extrusion Framing Aluminium Extrusion Stainless Steel Mesh Aluminum Foil Membrane Pleated Mesh Reinforcing Mesh Aluminum Mending Plate Polypropylene Mesh Melting Aluminum Foil Expanded Plastic Mesh Aluminum Foil Mixture Stainless Steel Screening Mesh Metric Aluminum Plate Aluminum Metric Screws Aluminum Resin Mosaic Mesh Melt Aluminum Foil Aluminum Foil Melt Polyester Pleated Mesh Melted Aluminum Foil Casting Aluminum Alloy Fine Mesh Mesh Window Screen Plastic Fence Mesh Cold Forming AluminumAluminium Modelling Mesh Supplier & Manufacturer from China

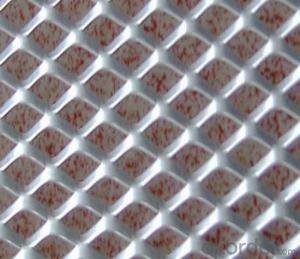

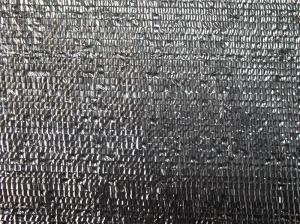

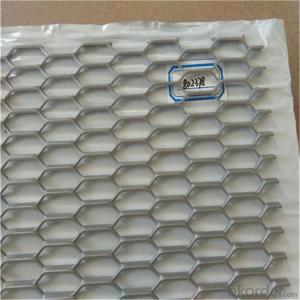

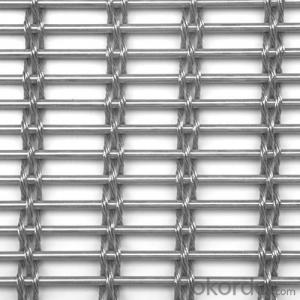

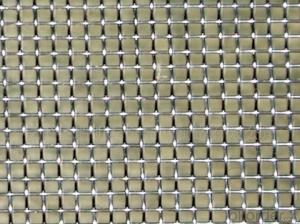

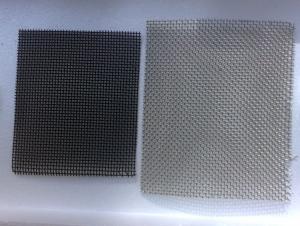

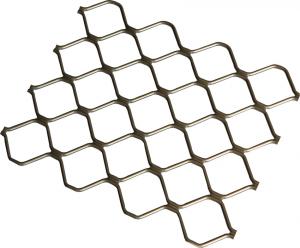

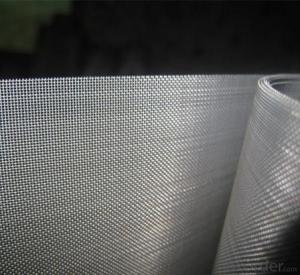

Aluminium Modelling Mesh is a versatile product made from high-quality aluminum material, designed for various applications in construction, architecture, and design. This product offers excellent durability and strength, making it an ideal choice for projects that require lightweight yet robust materials. Its unique properties also contribute to energy efficiency and sustainability, making it a popular choice among professionals in the industry.Aluminium Modelling Mesh is widely used in a range of applications, including facade cladding, interior decoration, and architectural accents. Its lightweight nature and ease of installation make it a preferred choice for both new constructions and renovation projects. Additionally, its corrosion-resistant properties make it suitable for use in various environments, from urban settings to coastal areas. This product can also be customized to meet specific design requirements, allowing for greater flexibility and creativity in project execution.

Okorder.com is a leading wholesale supplier of Aluminium Modelling Mesh, boasting a large inventory to cater to the diverse needs of clients worldwide. With a commitment to quality and customer satisfaction, Okorder.com ensures that each Aluminium Modelling Mesh product is manufactured to the highest standards. By partnering with Okorder.com, customers can benefit from competitive prices, prompt delivery, and excellent after-sales support, making it a reliable choice for sourcing Aluminium Modelling Mesh for any project.

Hot Products