Aluminium Profile for Mechanical Engineering

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Aluminium Profile for Mechanical Engineering Description

Aluminium Profile for Mechanical Engineering is one semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Aluminium Profile for Mechanical Engineering

Aluminium Profile for Mechanical Engineering | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Aluminium Profile for Mechanical Engineering

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Aluminium Profile for Mechanical Engineering

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Aluminium Profile for Mechanical Engineering

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

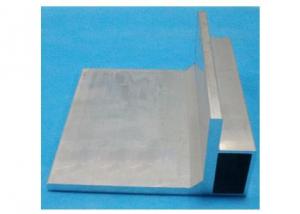

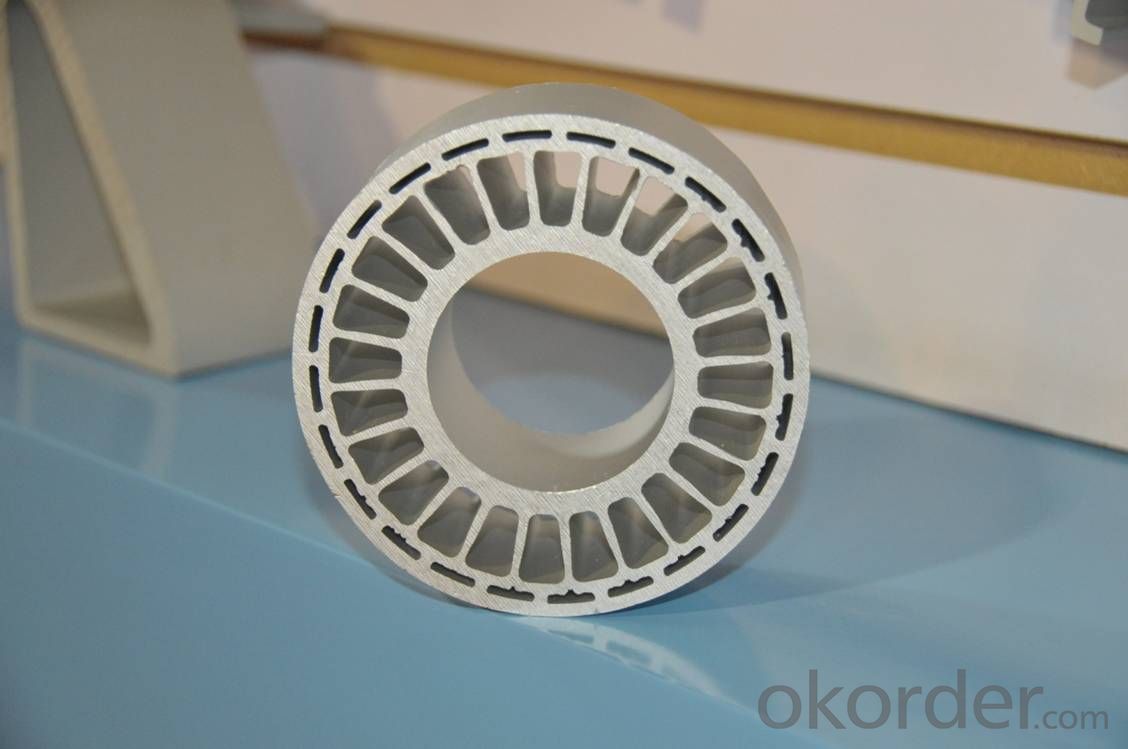

6. Image of Aluminium Profile for Mechanical Engineering

7. Package and shipping of Aluminium Profile for Mechanical Engineering

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: This question seeks to understand the various types of aluminum profiles that are specifically utilized in the construction of railings and fences.

- <p>Aluminum profiles for railings and fences come in various types, each designed for specific applications and aesthetic preferences. Common types include: 1) Rectangular profiles, which are versatile for both commercial and residential settings; 2) Square profiles, offering a modern look and are often used in minimalist designs; 3) Round profiles, providing a classic appearance suitable for traditional or vintage styles; 4) Slotted profiles, which allow for easy assembly and are popular for their adjustability; 5) Hollow profiles, known for their strength and lightness, ideal for high-load applications; 6) Angled profiles, used to create corners and intersections in railing and fence designs. Each type can be further customized in terms of size, thickness, and finish to meet specific project requirements.</p>

- Q: Can someone give me a direction? Thank you

- First of all, the country's biggest industrial enterprise profile Liaoning Zhongwang Liaoyuan Midas Shandong Shandong Hunan Guangxi South Nanshan jungle Sheng Tong Guangdong Luxe Guangdong and the United States they have or will soon be launched high-speed EMU industrial aluminum productsSecondly, the radiator done the best Guangxi south south aluminum, but the radiator specification too, radiator section do few enterprises, the majority of enterprises in the decentralized radiator, small cross section, you have to search.The best solar energy company is Jiangsu's Hyde aluminum, energy aluminum enterprises concentrated in Jiangsu and Zhejiang, it is recommended search.Mechanical equipment is divided into manufacturing machinery and medical equipment manufacturing machinery, aluminum is not much, much maintenance need new materials will purchase, medical devices are mostly aluminum fittings and seamless pipe, little section, which can satisfy the production enterprises can do.Transport can be divided into passenger cars and commercial vehicles in two categories, now on the domestic market of aluminum on the vehicle in popularity is also very slow, promotion is difficult, this is not a salesman to project, to promote the use of a wide range of industry to the understanding, or executive strategy, and promote the country policy......The one or two sentence that is not clear, industry market is still relatively confused, capacity is already saturated, according to the perspective of industrial development, 120% saturated, is conducive to healthy competition, eliminating inferior enterprises, promote the development of technology, but has been more than 150% saturated capacity in China, most are small extrusion machine for the production of building, 70% how to develop materials, industry, still have to see your company's positioning and strategic development.

- Q: Are aluminum profiles suitable for constructing interior partitions or ceilings in commercial buildings?

- <p>Yes, aluminum profiles are commonly used for interior partitions and ceilings in commercial buildings. They offer several advantages such as strength, durability, and resistance to corrosion. Aluminum profiles are lightweight, easy to install, and can be custom designed to fit specific architectural requirements. They also provide good thermal insulation and can be used in both new constructions and renovations.</p>

- Q: Can aluminum profiles be used in lighting fixture manufacturing?

- Aluminum profiles are indeed suitable for the manufacturing of lighting fixtures. In the lighting industry, aluminum is widely employed because of its many advantageous qualities. It possesses light weight, durability, and corrosion resistance, which make it perfect for both indoor and outdoor lighting fixtures. By easily molding and manipulating aluminum profiles, one can create diverse designs and forms, thereby enabling innovative and imaginative lighting solutions. Moreover, these profiles can be coated or anodized, thereby enhancing their visual appeal and providing extra protection against damage. All in all, due to their versatility, functionality, and aesthetic appeal, aluminum profiles are highly favored in the manufacturing of lighting fixtures.

- Q: Are aluminum profiles suitable for use in chemical processing environments?

- Aluminum profiles prove to be a suitable option for utilization within chemical processing environments. This versatile and corrosion-resistant material possesses the ability to endure exposure to a vast array of chemicals. Its exceptional resistance extends to numerous common chemicals, encompassing acids, bases, and solvents. Furthermore, aluminum profiles can acquire additional protection through the application of specialized coatings or finishes, like anodizing, which heightens their resistance against chemical corrosion. Moreover, within chemical processing environments, aluminum profiles present other advantages, such as their lightweight composition, high strength-to-weight ratio, and simple fabrication techniques. These qualities render aluminum profiles a favored choice for various applications in chemical processing industries, including the construction of tanks, piping systems, and process equipment.

- Q: This question asks for guidance on selecting the appropriate size and shape of aluminum profiles for a specific application.

- <p>Choosing the right size and shape of an aluminum profile involves several steps. First, consider the load-bearing requirements and structural integrity needed for your application. Consult with engineering standards or use software that can simulate the stress and load on the profile. Second, consider the aesthetic and functional requirements, such as the profile's visibility and the need for specific features like slots or holes. Third, review the available profiles from suppliers, matching your needs with their offerings. Finally, prototype with the selected profile to ensure it meets all requirements before full-scale production. Always consult with aluminum profile manufacturers or suppliers for their expertise and recommendations.</p>

- Q: Are aluminum profiles suitable for constructing energy-efficient buildings?

- <p>Yes, aluminum profiles can be used to create energy-efficient building designs. They are lightweight, strong, and have excellent thermal conductivity, which can be utilized to design structures with reduced heat transfer, thereby improving energy efficiency. Aluminum profiles can also be used in combination with insulating materials to enhance thermal insulation. Their recyclability and low maintenance requirements contribute to sustainability, further supporting energy-efficient construction practices.</p>

- Q: How do you clean and maintain aluminum profiles?

- Here are some straightforward steps to clean and maintain aluminum profiles: 1. Begin by eliminating loose dirt or debris from the aluminum profiles' surface using a soft brush or cloth. 2. Create a cleaning solution by combining warm water with mild dish soap or a non-abrasive cleaner. Avoid using harsh chemicals or abrasive cleaners since they can harm the aluminum finish. 3. Immerse a gentle cloth or sponge into the cleaning solution and delicately scrub the aluminum profiles, ensuring that all corners and crevices are thoroughly cleaned. 4. Rinse the profiles with clean water to remove any soap residue. You can accomplish this by using a hose or a bucket of water. 5. Dry the aluminum profiles entirely using a soft, lint-free cloth. This will prevent the formation of water spots or streaks. 6. For routine maintenance, you can employ a specialized aluminum cleaner or polish to restore the shine and safeguard the surface. Follow the product instructions for optimal outcomes. 7. It is crucial to refrain from using abrasive scrubbers, steel wool, or harsh chemicals as they can scratch or damage the aluminum finish. Additionally, never apply acidic cleaners or vinegar on aluminum since they can cause corrosion. 8. If you happen to notice any scratches or minor damages on the aluminum profiles, you can employ a touch-up paint specifically designed for aluminum to repair them. Follow the manufacturer's instructions for application. Always remember that regular cleaning and maintenance will aid in preserving the appearance and longevity of your aluminum profiles.

- Q: What are the noise insulation properties of aluminum profiles?

- Aluminum profiles have relatively poor noise insulation properties compared to other materials commonly used for soundproofing, such as wood or PVC. Aluminum is a lightweight and thin material, which allows sound waves to easily pass through it. It does not provide a significant barrier to block or absorb sound, resulting in minimal noise reduction. However, certain aluminum profiles can be designed with additional features to enhance their noise insulation capabilities, such as incorporating insulating materials or using thicker profiles. These modifications can improve the soundproofing performance to some extent, but it still may not be as effective as other materials specifically designed for noise insulation.

- Q: What is the tolerance of aluminum profile extrusion?

- 2, precision extrusion technology requirementsIn general, the degree of Aluminum Alloy hot extrusion deformation, the influence of extrusion temperature and speed change, the extrusion equipment of neutral and die deformation are easy to profile precision, and their mutual influence factors is difficult to overcome. Figure 3 presents the factors affecting precision extrusion.3 、 requirements for toolingThe mold is the most direct factor to affect the product size precision extrusion, extrusion products to ensure that in the production section size or minor change, must make the mould rigidity, heat resistance, wear resistance can reach a certain requirement.First of all to ensure that the mold is not easy deformation under high temperature and high pressure, have very high heat resistance, the precision extrusion is more strict requirements in working temperature (500 degrees Celsius), the yield strength of the die material is not less than 1200N/mm2. then need to have high wear resistance, which mainly depends on the hardness and thickness of the nitrided layer. The general requirements of the hardness of the nitrided layer above 1150HV, depth of the nitrided layer between 0.25 mm and 0.45mm, and the changes after nitriding die size should be less than 0.02mm.For solid profile and hollow profile cantilever has cross section, but also consider the die elastic deformation, in order to make the mould to ensure certain rigidity, can be considered appropriate to increase the thickness of the mould with a special pad or similar shapes.Change control profile opening size, can be in the mold to control metal flow channel groove.

Send your message to us

Aluminium Profile for Mechanical Engineering

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords