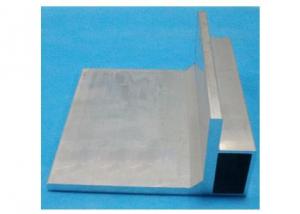

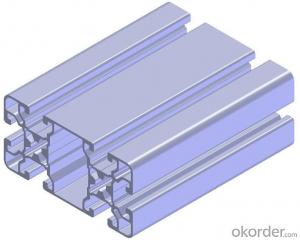

Stock Aluminum Profiles

Stock Aluminum Profiles Related Searches

Stock Aluminum Stock Aluminum Shapes Aluminum Stock Aluminum Stock Companies Aluminum Stock Prices Aluminum Manufacturers Stock Aluminum Price Stock Aluminum Frame Stock Aluminum Stock Material Aluminum Stock Sizes Aluminum Companies Stock Extruded Aluminum Stock Shapes Us Aluminum Stock Stock Market Aluminum Stock Symbol For Aluminum Aluminum Stock Box Aluminum Stock Quote Aluminum Stock Thickness Aluminum Stock Market Aluminum Metal Stock Buy Aluminum Stock Aluminum Ak Stock Us Aluminum Companies Stock 2 Aluminum Stock American Aluminum Stock Aluminum Stock Symbol Aluminum Stock Bar China Aluminum Stock Aluminum Stock For Sale Aluminum Chassis StockStock Aluminum Profiles Supplier & Manufacturer from China

Stock Aluminum Profiles are a range of aluminum extrusions designed for various industrial applications, offering a versatile and lightweight solution for numerous projects. These profiles are widely used in construction, automotive, aerospace, and electronics industries due to their strength, durability, and corrosion resistance. They are also appreciated for their ease of customization and assembly, making them an ideal choice for a variety of usage scenarios. Okorder.com is a leading wholesale supplier of Stock Aluminum Profiles, boasting a vast inventory that caters to the diverse needs of clients across different sectors. With their extensive range and competitive pricing, Okorder.com ensures that customers can find the perfect Stock Aluminum Profiles for their specific requirements.Hot Products