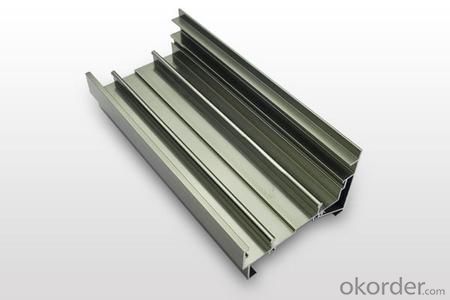

Aluminum Threshold Profiles for Any Application

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We provide a full range of precision aluminum strip for almost any application. We produce aluminum strip in a wide variety of alloys, including clad composites. Our aluminum strip can be produced in standard dimensions or custom made to your special requirements. We produce both imperial and metric units. We manufacture in compliance with the main international specifications, and tighter tolerances or custom tempers are available upon request. We offer various surface conditions, custom finishes (painting, anodizing, embossing), special processing, and multiple packaging options to meet our customer's unique requirements. The following is a summary of our capabilities.

Manufactured in compliance with the main international specifications and standards, including: Aluminum Association, ASTM, EN, and DIN.

We can also manufacture in compliance with other international standards including:ASME, SAE, AMS, AWS, FED, MIL, QQ, ISO, BS, AFNOR, JIS and GOST.

Manufactured in compliance with the main international specifications and standards.

Tighter tolerances are available upon request.

Aluminium (or aluminum; see spelling differences) is a chemical element in the boron group with symbol Al and atomic number 13. It is a silvery white, soft, ductile metal. Aluminium is the third most abundant element (after oxygen and silicon), and the most abundant metal in the Earth's crust. It makes up about 8% by weight of the Earth's solid surface. Aluminium metal is so chemically reactive that native specimens are rare and limited to extreme reducing environments. Instead, it is found combined in over 270 different minerals.The chief ore of aluminium is bauxite.

Aluminium is remarkable for the metal's low density and for its ability to resist corrosion due to the phenomenon of passivation. Structural components made from aluminium and its alloys are vital to the aerospace industry and are important in other areas of transportation and structural materials. The most useful compounds of aluminium, at least on a weight basis, are the oxides and sulfates.

Despite its prevalence in the environment, no known form of life uses aluminium salts metabolically. In keeping with its pervasiveness, aluminium is well tolerated by plants and animals. Owing to their prevalence, potential beneficial (or otherwise) biological roles of aluminium compounds are of continuing interest.

- Q: Can aluminum profiles be used for signage or display purposes?

- Yes, aluminum profiles can definitely be used for signage or display purposes. Aluminum is a versatile and durable material that is commonly used in various industries, including signage and display. Aluminum profiles provide a strong framework for signs and displays, allowing for stability and longevity. The lightweight nature of aluminum makes it easy to handle and install, making it a popular choice for outdoor signage and indoor displays. Additionally, aluminum profiles can be easily customized and fabricated into various shapes and sizes, allowing for creativity and design flexibility. Aluminum profiles also offer excellent resistance to corrosion, ensuring that the signage or display remains in good condition even in outdoor or high-moisture environments. This makes them suitable for a wide range of applications, including storefront signs, directional signs, trade show displays, exhibition booths, and many more. Furthermore, aluminum profiles can be powder coated or anodized to provide a decorative finish, enhancing the visual appeal of the signage or display. This allows for branding and customization options, making the aluminum profiles a great choice for businesses looking to showcase their brand identity. Overall, aluminum profiles are a reliable and versatile choice for signage or display purposes. They offer strength, durability, design flexibility, and resistance to corrosion, making them suitable for a wide range of applications in various industries.

- Q: Can aluminum profiles be used for modular storage systems?

- Yes, aluminum profiles can be used for modular storage systems. Aluminum is a lightweight and durable material that is commonly used in various industries, including storage and shelving systems. Its versatility allows for easy customization and the ability to create modular units that can be easily assembled, disassembled, and reconfigured as needed. Additionally, aluminum profiles provide a sleek and modern aesthetic to storage systems.

- Q: This question asks for methods to guarantee the safety and reliability of aluminum profile installations.

- <p>To ensure that the installation of aluminum profiles is safe and reliable, follow these steps: Use high-quality aluminum profiles that meet industry standards. Ensure proper measurements and accurate cuts to fit the profiles perfectly. Use appropriate fasteners and hardware that are compatible with aluminum. Ensure that all connections are secure and that the profiles are properly aligned. Check for any sharp edges or protrusions that could cause injury. Test the stability and load-bearing capacity of the installation to ensure it can handle the expected weight and stress. Regularly inspect and maintain the aluminum profiles to prevent any potential issues.</p>

- Q: What are the ten brands of aluminum alloy profiles?

- Top ten list of Chinese aluminum profiles Enterprises1 、 aluminum material(China Aluminum Group, China's top ten aluminum enterprises, central management of large state-owned enterprises)2 - Asia - South Asia(China famous trademark, China famous brand, China aluminum profile enterprise ten, Guangdong Asia Aluminum Factory Co., Ltd.)3, the United States and aluminum(A Well-Known Trademark in China, China brand, China aluminum enterprise ten, Guangdong Jianmei Aluminum Profile Factory Co., Ltd.)4, the phoenix aluminum aluminum(China famous brand, famous brand in Guangdong Province, Guangdong province famous brand products, Guangdong Feng Aluminum Co. Ltd.)5, Zhong Wang aluminum(China famous brand, China famous brand, Liaoning famous brand product, China Zhong Wang Holdings Limited)6, Hing Fat aluminum(China brand, A Well-Known Trademark in China, China aluminum enterprise ten, Xingfa Aluminum Holdings Limited)7, pillars of aluminum(listed companies, Chinese famous brands, China's well-known trademarks, China's aluminum enterprises ten, Zhejiang pillars, new materials, Limited by Share Ltd)8 、 Nanshan aluminum material(China famous brand, China well-known trademark, ten aluminum profile enterprises in China, Shandong Nanshan aluminum & Limited by Share Ltd)9, the court aluminum profiles(China's well known trademark, China's top ten aluminum enterprises, Polytron Technologies Inc, Shanghai aluminum Fair)10, Albert aluminum(China famous brand, Guangdong famous brand, Guangdong famous brand product, Guangdong Weiye aluminium factory Co., Ltd.)

- Q: This question asks for guidance on selecting the appropriate aluminum profiles for a construction project.

- <p>Choosing the right aluminum profiles for your building project involves several steps. First, consider the specific requirements of your project, such as load-bearing capacity, aesthetic preferences, and environmental conditions. Consult with engineers or architects to determine the appropriate strength, size, and shape of the profiles. Next, evaluate the quality of the aluminum, ensuring it meets industry standards for durability and resistance to corrosion. Look for profiles with good thermal insulation properties and UV resistance to maintain performance over time. Finally, consider the cost-effectiveness and availability of the profiles, as well as the ease of installation and maintenance. Always opt for reputable suppliers to ensure you receive high-quality products that meet your project's needs.</p>

- Q: What are the safety regulations concerning the use of aluminum profiles in construction?

- <p>Yes, there are safety regulations related to the use of aluminum profiles in construction. These regulations vary by country and region but generally include requirements for material strength, durability, and resistance to environmental factors. Standards such as ASTM B221 for aluminum and aluminum alloy extruded bars, rods, and profiles, and ISO 6361 for aluminum and aluminum alloy extruded profiles, provide guidelines on dimensions, tolerances, and mechanical properties. Compliance with local building codes and regulations is crucial, which may include fire resistance, load-bearing capacity, and corrosion resistance. Additionally, proper installation practices and adherence to manufacturer's specifications are essential to ensure safety and structural integrity.</p>

- Q: What is the difference between aluminum profile and sheet metal?

- Profile, as the name suggests, is a variety of complex shapes of aluminum, plates only flat type aluminum.

- Q: Are aluminum profiles suitable for awnings and canopies?

- Awnings and canopies find aluminum profiles to be exceptionally fitting. Aluminum, being a lightweight material, possesses durability and resistance to rust and corrosion, making it an ideal choice for outdoor purposes. Moreover, it allows for effortless customization in terms of shape and size. Furthermore, aluminum profiles can be powder-coated to further guard against the elements and augment their visual allure. In summary, aluminum profiles present a robust and adaptable solution for constructing awnings and canopies that endure diverse weather conditions while providing shade and safeguarding.

- Q: What are the different shapes available for aluminum profile cross-sections?

- There are numerous shapes available for aluminum profile cross-sections, including but not limited to, square, rectangular, round, T-shaped, I-shaped, U-shaped, L-shaped, and hexagonal.

- Q: This question asks for methods to protect aluminum profiles from corrosion and damage during the processes of transportation and storage.

- <p>To prevent corrosion and damage to aluminum profiles during transportation and storage, follow these guidelines: 1. Keep aluminum profiles dry and clean. Moisture and dirt can accelerate corrosion. 2. Use protective packaging, such as plastic wrap or padded covers, to shield profiles from physical damage and moisture. 3. Store profiles in a cool, dry place away from direct sunlight and corrosive substances. 4. Stack profiles with appropriate padding between layers to prevent scratching. 5. Avoid overloading during transportation and ensure secure fastening to prevent movement and potential damage. 6. Regularly inspect stored profiles for signs of corrosion or damage and address any issues promptly.</p>

Send your message to us

Aluminum Threshold Profiles for Any Application

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords