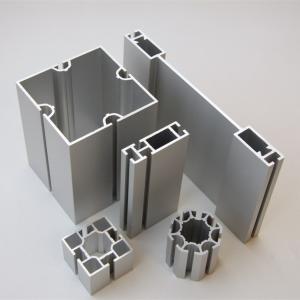

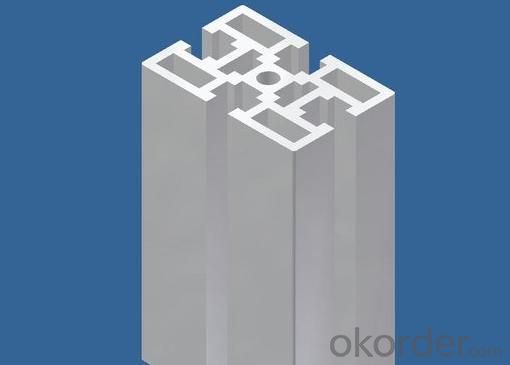

2020 T-Slot Aluminum Profiles Extrusion 6063-T5

- Loading Port:

- ShenZhen

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons kg

- Supply Capability:

- 1000 Tons Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1 Specifications of Aluminum Profiles 6063-T5

Alloy Number | 6063 6061 6060 and different aluminium alloy |

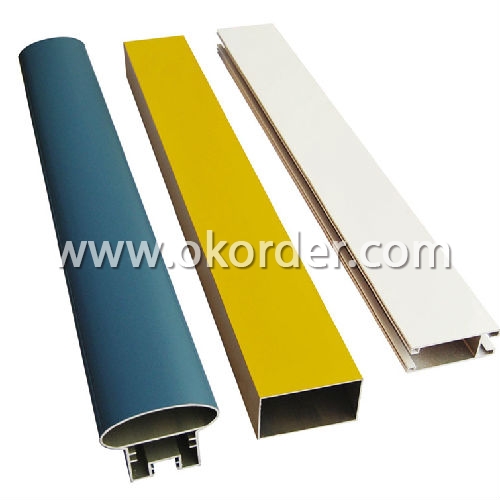

Temper | T4 T5 T6 or other special status |

Surface available | Mill finish, Anodized, Powder Coating, Wooden transfering, electrophoresis, heat insulation, PVDF, and deep processing |

Thickness: | >0.8mm |

Width: | <300mm |

Standard | GB5237.1-2008 |

Special Specification is available on customer’s requirement

2 Usage/Applications of Aluminum Profiles 6063-T5

Aluminium Profiles are widely used in construction(windows & doors,curtain wall), decoration ( flooring and tiling, kitchen) and industry ( heat sink ).

CNBM produces aluminum profiles which meets the national standard GB5237.1-2008. Our strong quality control term bring you the most-qualified products. And with state-of-the-art equipment, and the state owned company background, we have to say, you will understand why there are so many company choose CNBM to be their supplier.

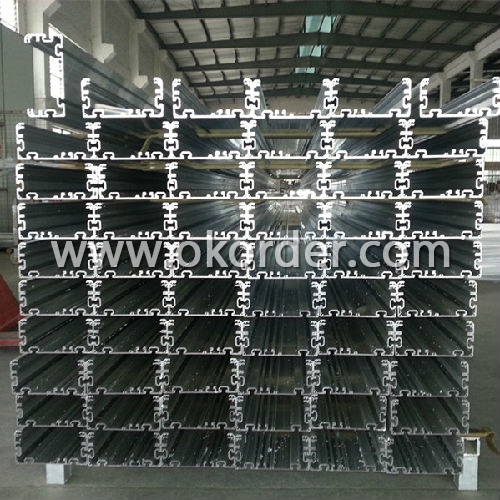

3 Packaging & Delivery of Aluminum Profiles 6063-T5

Packaging: Seaworthy package, bubble plastic bag inside, anti-moisture paper wrapped outside, covered with cartons, on wooden pallets, in containers.

Shipment: the goods will be delivered in 15-30days after getting the buyer's payment.

4 Production Flow of Aluminum Profiles 6063-T5

aluminium ingot & alloy→melting and casting→extrusion→powder coating→pouring rubber for heat insulation→checkout→packing→PVDF coating\anodizing\electrophoresis→put in products warehouse.

- Q: Are aluminum profiles resistant to pests or insects?

- Yes, aluminum profiles are generally resistant to pests or insects. Due to their non-porous and smooth surface, pests and insects find it difficult to penetrate or damage aluminum profiles.

- Q: What are the surface hardness properties of aluminum profiles?

- The surface hardness properties of aluminum profiles can vary depending on the specific alloy and treatment processes applied. Aluminum alloys are generally known for having a lower hardness compared to other metals such as steel. However, through various treatments, aluminum profiles can achieve improved surface hardness. One common treatment method is anodizing, which involves creating an oxide layer on the surface of the aluminum. This process not only enhances the corrosion resistance of the profiles but also increases their surface hardness. Anodized aluminum profiles can have a hardness ranging from 150 to 300 HV (Vickers hardness), depending on the thickness of the oxide layer. Another treatment process is hard coating, where a ceramic material such as aluminum oxide is applied to the surface of the profiles. This coating significantly enhances the hardness of the aluminum, providing a greater level of wear resistance. The hardness of hard-coated aluminum profiles can range from 400 to 600 HV or even higher. It is important to note that the specific hardness properties can vary depending on the alloy composition, surface treatment method, and the desired application of the aluminum profiles. Therefore, it is crucial to consult with manufacturers or suppliers to determine the appropriate hardness properties that best suit your specific needs.

- Q: This question asks for a variety of green building materials that incorporate recycled aluminum profiles, indicating an interest in sustainable construction practices.

- <p>Recycled aluminum profiles are used in various green building materials to promote sustainability. These include: 1) Window and door frames, known for their durability and energy efficiency. 2) Facade systems, which provide a lightweight and strong alternative to traditional materials. 3) Structural components, such as beams and columns, offering strength with less material. 4) Roofing materials, which can be lightweight and resistant to corrosion. 5) Modular building systems, which use prefabricated aluminum components for quick assembly. 6) Fencing and railings, offering a low-maintenance option. 7) Solar panel supports, combining recycled aluminum with renewable energy technology. These materials reduce waste, save energy, and lower carbon emissions in construction.</p>

- Q: What are the safety regulations concerning the use of aluminum profiles in construction?

- <p>Yes, there are safety regulations related to the use of aluminum profiles in construction. These regulations vary by country and region but generally include requirements for material strength, durability, and resistance to environmental factors. Standards such as ASTM B221 for aluminum and aluminum alloy extruded bars, rods, and profiles, and ISO 6361 for aluminum and aluminum alloy extruded profiles, provide guidelines on dimensions, tolerances, and mechanical properties. Compliance with local building codes and regulations is crucial, which may include fire resistance, load-bearing capacity, and corrosion resistance. Additionally, proper installation practices and adherence to manufacturer's specifications are essential to ensure safety and structural integrity.</p>

- Q: What are the different sealing options for aluminum profiles?

- There are several sealing options available for aluminum profiles, including anodizing, powder coating, liquid paint coating, and mechanical sealing. Anodizing is a popular choice, providing a durable and corrosion-resistant finish by creating a protective oxide layer on the surface of the aluminum. Powder coating involves applying a dry powder to the profile, which is then cured under heat to form a hard, smooth coating. Liquid paint coating can also be used, offering various colors and finishes, but may require more maintenance. Mechanical sealing involves using gaskets, tapes, or other sealing materials to create a tight seal between aluminum profiles. The choice of sealing option depends on the specific requirements of the application, such as desired aesthetics, durability, and environmental factors.

- Q: This question asks about the various surface treatments or finishes that can be applied to aluminum extrusions, which are shaped profiles made from aluminum.

- <p>Aluminum extrusions can be finished in several ways to enhance their appearance, durability, or functionality. Common finishes include anodizing, which provides a protective oxide layer; powder coating, offering a wide range of colors and textures; painting, which can be done electrostatically or by hand; polishing, resulting in a shiny, smooth surface; brushing, which creates a satin-like finish; and chromate conversion coating, which is a pretreatment for further painting or coating. Other finishes include wood grain transfer, which gives an aluminum surface a wood-like appearance, and various types of protective films or laminates. Each finish serves different purposes, from improving aesthetics to increasing corrosion resistance.</p>

- Q: What does T6 mean in aluminum alloy sections?

- The aluminum alloy heat treatment process of the broken bridge aluminum profile: the specific content is as follows:T6 is the deformation of Aluminum Alloy (distinguished from casting Aluminum Alloy) a heat treatment process, is "solid solution treatment (for steel in this process is called" quenching ", everyone should be very familiar with) + artificial aging process", of which the main factor is the solid solution temperature, quenching rate (determined by the quenching medium) and the aging temperature, holding time, time series (an aging or ageing).For different alloys, the same heat treatment code, such as T6, contains values that vary from one factor to another.This process is distinguished from what is commonly known as an annealing process.This process is the key to solving the problems of strength, plasticity, reasonable collocation (high strength and sufficient plasticity) and corrosion resistance.Without deformation of alloy Txxx processing, is absolutely can not be used as a structural material, will be mine, so please rest assured that your car frame (if not from the black hearted miners workshop) must have been processed.2014 aluminum alloy commonly used heat treatment state code has T6, T62, T651 (E), different product shape processing process is slightly different.My MOSSO car shelf is 7005 alloy, the usual process is T53 (V), do not write above also know.Handlebar and handlebar immediately 6061 aluminum alloy T6The above aluminum alloys are all foreign brands

- Q: Can aluminum profiles be used in the construction of solar panels?

- Solar panels can indeed incorporate aluminum profiles in their construction. Aluminum, a lightweight and durable material, finds widespread use across industries, including construction and solar energy, due to its numerous advantages. To begin with, aluminum profiles offer structural support and stability to solar panel systems. They can be easily molded into various shapes, enabling flexibility during panel assembly. Moreover, aluminum boasts exceptional corrosion resistance, guaranteeing the panels' longevity and durability in diverse weather conditions. In addition, aluminum profiles possess high conductivity, a crucial factor for the efficient operation of solar panels. By effectively dissipating heat produced by the solar cells, they prevent overheating and amplify the panels' overall performance and lifespan. Furthermore, aluminum stands as a sustainable and environmentally-friendly material. Its easy recyclability and reusability significantly decrease the environmental impact of solar panel production. This aligns with the principles of renewable energy and sustainability, making aluminum profiles the preferred choice in solar panel construction. In conclusion, the utilization of aluminum profiles in solar panel construction is a practical and efficient choice due to their structural strength, resistance to corrosion, thermal conductivity, and sustainability. By incorporating aluminum profiles, solar panel systems can ensure reliability, efficiency, and environmental friendliness.

- Q: What are the specific needs or standards for utilizing aluminum profiles in cold weather conditions?

- <p>In cold climates, aluminum profiles must meet certain requirements to ensure durability and functionality. These include resistance to extreme temperatures, which may affect the material's strength and flexibility. Profiles should be made from high-quality aluminum alloys designed for low-temperature performance. Additionally, proper thermal breaks may be necessary to prevent heat loss through the profile. Corrosion resistance is also crucial, as cold environments can accelerate the process. Lastly, it's essential to consider the expansion and contraction of aluminum in cold temperatures, ensuring the design accommodates these changes to prevent warping or cracking.</p>

- Q: Are aluminum profiles suitable for use in exterior wall insulation systems?

- <p>Yes, aluminum profiles can be used for exterior wall insulation systems. They are known for their durability, resistance to corrosion, and ability to withstand various weather conditions. Aluminum profiles provide a strong structural framework that can support insulation materials effectively. They are also lightweight, which makes them easy to handle and install. Additionally, aluminum profiles can be anodized or coated to enhance their resistance to environmental factors, making them a popular choice for exterior insulation systems.</p>

1. Manufacturer Overview

| Location | Guangdong, China |

| Year Established | 2006 |

| Annual Output Value | Above US$50 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Nanhai Port |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

2020 T-Slot Aluminum Profiles Extrusion 6063-T5

- Loading Port:

- ShenZhen

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons kg

- Supply Capability:

- 1000 Tons Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords