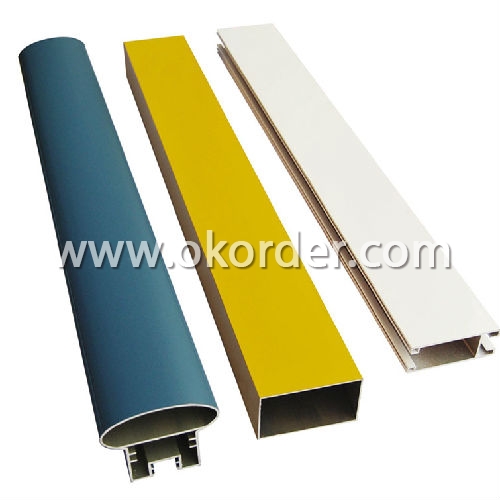

Aluminum Hollow Profiles AA8XXX

- Loading Port:

- ShenZhen

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1 Specifications of Aluminum Profiles AA8xxx

Alloy Number | 6063 6061 6060 and different aluminium alloy |

Temper | T4 T5 T6 or other special status |

Surface available | Mill finish, Anodized, Powder Coating, Wooden transfering, electrophoresis, heat insulation, PVDF, and deep processing |

Thickness: | >0.8mm |

Width: | <300mm |

Standard | GB5237.1-2008 |

Special Specification is available on customer’s requirement

2 Usage/Applications of Aluminum Profiles AA8xxx

Aluminium Profiles are widely used in construction(windows & doors,curtain wall), decoration ( flooring and tiling, kitchen) and industry ( heat sink ).

CNBM produces aluminum profiles which meets the national standard GB5237.1-2008. Our strong quality control term bring you the most-qualified products. And with state-of-the-art equipment, and the state owned company background, we have to say, you will understand why there are so many company choose CNBM to be their supplier.

3 Packaging & Delivery of Aluminum Profiles AA8xxx

Packaging: Seaworthy package, bubble plastic bag inside, anti-moisture paper wrapped outside, covered with cartons, on wooden pallets, in containers.

Shipment: the goods will be delivered in 15-30days after getting the buyer's payment.

4 Production Flow of Aluminum Profiles AA8xxx

aluminium ingot & alloy→melting and casting→extrusion→powder coating→pouring rubber for heat insulation→checkout→packing→PVDF coating\anodizing\electrophoresis→put in products warehouse.

- Q: 6063 aluminum manufacturers fail to notice how to write a written report

- Hello!You can search the Internet for unqualified written reports, and see if there are similar onesYou see, you sign the contract, which has not marked this point, say how to deal with substandard, you just need to copy the above, make a little change on the line

- Q: Can aluminum profiles be recycled and reused for interior wall cladding purposes?

- <p>Yes, aluminum profiles can be recycled and reused in interior wall cladding applications. Aluminum is a highly recyclable material, and its recycling process does not degrade its properties, making it an excellent choice for sustainable construction. Recycled aluminum profiles can be used to create new wall cladding systems, reducing waste and the environmental impact of mining and processing new aluminum. This practice not only conserves natural resources but also contributes to energy savings and a lower carbon footprint.</p>

- Q: What are the methods to prevent water infiltration in the gaps between aluminum profiles during the installation process?

- <p>To prevent water from getting into gaps between aluminum profiles during installation, use high-quality sealants and gaskets. Ensure proper alignment and fit of the profiles to minimize gaps. Install weep holes to allow water to drain out. Apply a water-resistant membrane or flashing behind the profiles. Regularly inspect and maintain the installation to identify and fix any issues promptly. Proper installation techniques and materials selection are crucial to prevent water infiltration.</p>

- Q: Are aluminum profiles suitable for material handling equipment?

- Yes, aluminum profiles are suitable for material handling equipment. Aluminum is a lightweight and durable material that offers excellent strength-to-weight ratio, making it ideal for applications that require easy maneuverability and lifting capacities. Additionally, aluminum profiles can be easily customized and assembled, allowing for versatile designs that can meet various material handling needs.

- Q: What are the different surface sandblasting options for aluminum profiles?

- Aluminum profiles offer various options for surface sandblasting, each with its own distinctive finish and level of abrasiveness. 1. For a polished or satin appearance, fine sandblasting delicately eliminates surface imperfections, creating a smooth finish on the aluminum profile. This method employs fine-grain sand or abrasive materials. 2. To achieve a rugged texture, coarse sandblasting employs larger-grain sand or abrasives, providing a matte or textured finish on the aluminum surface. This option effectively conceals scratches and blemishes. 3. Glass bead blasting involves propelling small glass beads at high speed onto the aluminum profile's surface. This technique ensures a uniform and visually pleasing matte finish, often desired for its reflectivity. 4. Walnut shell blasting, a gentler approach compared to traditional sandblasting, utilizes ground walnut shells as the blasting media. This technique is suitable for delicate aluminum profiles, effectively removing contaminants and providing a clean, smooth finish. 5. Shot peening is a specialized sandblasting process that involves bombarding the aluminum profile with small metal shots or pellets. Primarily utilized to enhance strength and resistance to fatigue, shot peening focuses on improving the aluminum surface's durability rather than altering its appearance. Considering the specific requirements and desired outcome is crucial when selecting a surface sandblasting option for aluminum profiles. Consulting with professionals in the field can help determine the most suitable method based on the desired finish, level of abrasiveness, and the properties of the aluminum profile.

- Q: Is it possible to use aluminum profiles as materials for flooring?

- <p>Aluminum profiles can indeed be used for flooring materials, particularly in industrial or commercial settings. They are valued for their strength, durability, and resistance to corrosion. Aluminum profiles are often used in modular flooring systems, providing a stable and customizable base that can be easily adjusted or reconfigured. They are also appreciated for their lightweight nature, which can reduce the load on structures and facilitate installation. However, for residential applications, traditional flooring materials like wood, tile, or carpet are more common due to aesthetic and comfort considerations.</p>

- Q: Can aluminum profiles be used for furniture?

- Indeed, furniture can indeed be constructed using aluminum profiles. Aluminum, a flexible and light material, is often employed in furniture manufacturing. It presents numerous benefits, including resistance to corrosion, durability, and easy maintenance. It is possible to create various furniture pieces, such as tables, chairs, shelves, and cabinets, using aluminum profiles. These profiles can be conveniently customized and molded to adhere to specific design specifications. Moreover, they can be powder-coated or anodized to offer a decorative and enduring surface. All things considered, aluminum profiles are widely favored for furniture due to their robustness, adaptability, and visual charm.

- Q: What are the different welding options available for aluminum profiles?

- There are several welding options available for aluminum profiles, each with its own advantages and considerations. The most common welding methods for aluminum profiles include: 1. Tungsten Inert Gas (TIG) Welding: TIG welding is one of the most widely used methods for aluminum. It uses a non-consumable tungsten electrode to produce the weld, while an inert gas, such as argon, protects the weld area from atmospheric contamination. TIG welding offers excellent control over the heat input, resulting in high-quality, precise welds. It is suitable for thin aluminum profiles and provides a clean appearance, but it can be time-consuming and requires skilled operators. 2. Metal Inert Gas (MIG) Welding: MIG welding, also known as Gas Metal Arc Welding (GMAW), is another popular method for aluminum profiles. It uses a consumable wire electrode that continuously feeds into the weld pool, while an inert gas shield protects the weld area. MIG welding is faster than TIG welding and is suitable for both thin and thick aluminum profiles. However, it may produce more spatter and requires proper preparation and shielding gas selection. 3. Friction Stir Welding (FSW): Friction stir welding is a solid-state joining process that uses a rotating tool to generate heat and mechanically stir the aluminum profiles together. FSW is particularly suitable for thick aluminum profiles and offers high joint strength, excellent fatigue resistance, and minimal distortion. However, it requires specialized equipment and may not be suitable for all profile shapes. 4. Laser Beam Welding (LBW): Laser beam welding uses a highly concentrated laser beam to melt and join aluminum profiles. It provides a narrow and deep weld with minimal heat input, resulting in low distortion and high welding speeds. LBW is suitable for both thin and thick profiles, but it requires expensive equipment and skilled operators. 5. Resistance Spot Welding (RSW): Resistance spot welding uses electrical current and pressure to create welds by melting and joining aluminum profiles at specific points. RSW is commonly used for thin aluminum profiles and offers high productivity and repeatability. However, it requires access to both sides of the profiles and may leave visible marks on the surface. It is important to consider the specific requirements of your aluminum profile welding project, such as profile thickness, joint type, appearance, and production volume, to determine the most suitable welding method. Consulting with a welding professional or engineer can help ensure the best choice for your specific application.

- Q: Are aluminum profiles suitable for use in furniture fittings and accessories?

- Indeed, furniture fittings and accessories can benefit greatly from the use of aluminum profiles. This versatile material provides several advantages for furniture applications. Firstly, aluminum profiles are lightweight, making them easy to handle and install. This is particularly advantageous for furniture fittings and accessories that may require frequent adjustments or movements. In addition, aluminum profiles are highly durable and resistant to corrosion, ensuring that furniture fittings and accessories have a long lifespan. This makes them suitable for both indoor and outdoor furniture, as they can withstand various environmental conditions without deteriorating. Moreover, aluminum is highly customizable, allowing for a wide range of design options. It can be easily shaped, cut, and welded into various forms and sizes, enabling furniture designers to create unique and aesthetically pleasing fittings and accessories. Furthermore, aluminum profiles are low-maintenance and easy to clean, making them ideal for furniture applications. They can be easily wiped down or washed without the risk of damage or degradation. Additionally, aluminum is a sustainable and environmentally friendly material. It is 100% recyclable, meaning that it can be reused indefinitely without losing its properties. By utilizing aluminum profiles in furniture fittings and accessories, designers can contribute to a more sustainable and eco-friendly design approach. Overall, the combination of lightweight, durability, customization options, low-maintenance, and sustainability makes aluminum profiles an excellent choice for use in furniture fittings and accessories. They offer numerous benefits and can enhance the functionality, aesthetics, and longevity of furniture pieces.

- Q: What are the various standards and regulations governing the use of aluminum profiles in construction?

- <p>Aluminum profiles in construction are governed by a variety of standards and regulations that ensure their quality, safety, and performance. These include ISO standards such as ISO 7039 for anodized aluminum and ISO 9001 for quality management systems. National standards like ASTM B221 in the USA and EN 755 in Europe specify mechanical properties and chemical composition. Building codes such as the International Building Code (IBC) and Eurocode 9 also provide guidelines for the use of aluminum in construction. Additionally, there are specific regulations for fire resistance, sustainability, and environmental impact, like the European CE marking for construction products. Compliance with these standards is crucial for manufacturers and builders to ensure the reliability and safety of aluminum profiles used in construction projects.</p>

1. Manufacturer Overview

| Location | Guangdong, China |

| Year Established | 2006 |

| Annual Output Value | Above US$50 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Nanhai Port |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Aluminum Hollow Profiles AA8XXX

- Loading Port:

- ShenZhen

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords