Aluminum Extruded Tubing

Aluminum Extruded Tubing Related Searches

Aluminum Extrusions Extruded Aluminum Plate Extruded Aluminum Rail Extruded Aluminum Beams Aluminum Extrusion Plate Aluminium Extrusion Extruded Aluminum Heatsink Aluminum Tubing Coil Extruded Aluminum Track Aluminum Extrusion Framing Aluminum Extrusion Shapes Aluminum Electrical Wiring Large Diameter Aluminum Tube Aluminum Tape Extruded Aluminum Stock Aluminum Tubing Stock Aluminum Sealing Tape Conductive Aluminum Tape Extruded Aluminum Stock Shapes Bosch Aluminum Extrusion Extruded Aluminum I Beam Reinforced Aluminum Tape Square Stock Aluminum Tubing Aluminum Tube Coil Aluminium Tape Aluminum Coil Pipe 1 2 Aluminum Tubing Coil High Temperature Aluminum Tape Cold Forming Aluminum Brushed Aluminum TapeAluminum Extruded Tubing Supplier & Manufacturer from China

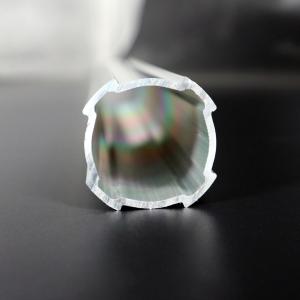

Aluminum Extruded Tubing is a versatile product made from aluminum alloy, which is known for its high strength-to-weight ratio and excellent corrosion resistance. This type of tubing is manufactured through a process called extrusion, where aluminum is heated and forced through a die to create a continuous profile with a uniform cross-section. The resulting product is a durable and lightweight tubing that is suitable for a wide range of applications.Aluminum Extruded Tubing is widely used across various industries due to its unique properties. It is commonly employed in construction, transportation, aerospace, and electronics, among others. The tubing can be found in applications such as structural components, framing systems, and mechanical parts, where its strength and lightweight nature are highly beneficial. Additionally, its corrosion resistance makes it an ideal choice for outdoor applications and environments where exposure to moisture is a concern.

Okorder.com is a reputable wholesale supplier of Aluminum Extruded Tubing, offering a vast inventory of this product to cater to the diverse needs of customers. With a commitment to quality and customer satisfaction, Okorder.com ensures that the Aluminum Extruded Tubing they provide meets the highest industry standards. Their extensive range of sizes, shapes, and specifications allows customers to find the perfect tubing for their specific requirements, making Okorder.com a go-to source for Aluminum Extruded Tubing.

Hot Products