Aluminum Extrusion Plate

Aluminum Extrusion Plate Related Searches

Extruded Aluminum Plate Aluminum Precision Plate Aluminum Extrusions Aluminum Traction Plate Precision Aluminum Plate Aluminum Oxide Plate Aluminium Extrusion Aluminum Pressure Plate Aluminum Diffuser Plate Aluminum Tool Plate Laser Cutting Aluminum Plate Aluminum Square Plate Aluminum Surface Plate Aluminum Metal Plate Aluminum Cover Plate Aluminum Mold Plate Aluminum Paper Plate Aluminum Cooking Plate Aluminum Structural Plate Aluminum Extruded Tubing Aluminum Profile Plate Decorative Aluminum Plate Aluminum Tooling Plate Aluminum Lapping Plate Aluminum Extrusion Shapes Aluminum Defrosting Plate Aluminum Cavitation Plate Aluminum Nitride Plate Laser Cut Aluminum Plate Aluminum Dimple PlateAluminum Extrusion Plate Supplier & Manufacturer from China

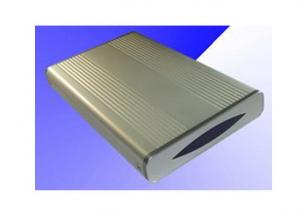

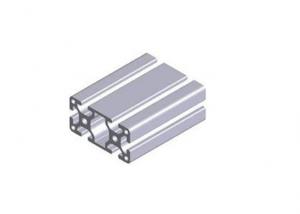

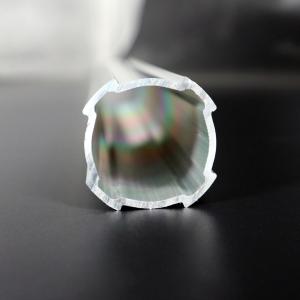

Aluminum Extrusion Plate is a versatile product made from aluminum alloys that are extruded into various shapes and sizes. These plates are known for their strength, durability, and lightweight properties, making them ideal for a wide range of applications. They are commonly used in construction, transportation, aerospace, and electronics industries due to their excellent performance and cost-effectiveness.Aluminum Extrusion Plate finds its application in various usage scenarios, such as window frames, door frames, furniture, and even in the manufacturing of automotive parts. The product's adaptability allows it to be tailored to specific needs, making it a popular choice for both commercial and industrial projects. Its corrosion resistance and recyclability also contribute to its appeal, as it offers an environmentally friendly solution for many applications.

Okorder.com is a renowned wholesale supplier of Aluminum Extrusion Plate, boasting a large inventory that caters to the diverse needs of clients across different industries. The company's commitment to quality and customer satisfaction ensures that customers receive top-notch products at competitive prices. With a wide selection of Aluminum Extrusion Plate available, Okorder.com is the go-to destination for those seeking reliable and efficient solutions for their aluminum extrusion needs.

Hot Products