Aluminium Extrusion Profiles For Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

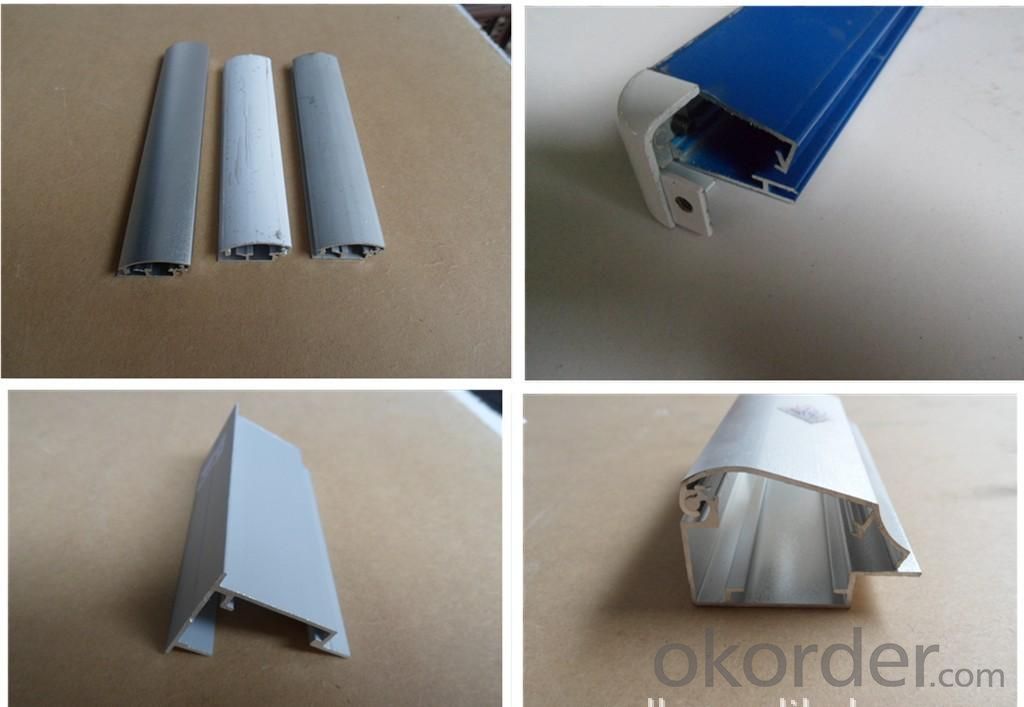

Product Name | Aluminium Extrusion Profiles For Construction |

Alloy | Al 6063 T5 /T6 or 6061 T4/T6 or as customers' need |

Surface | Aluminum profiles of mill finish, powder coating, anodizing, polishing, sand blasting, electrophoresis and wood color. |

Profile shape | According to drawings or re-design as requested or market needs. |

Price | Based on Aluminum Ingot Price + Process fee |

Payment term | T/C T/T 30% deposit and 70% pay against copy of B/L |

Certificate | ISO9001 ISO14001 |

Warranty | 1. GB5237-2008 equal to EN12020-1.2(2001); 2. Within 15 years without powder peeling off; |

Product Advantages

1. Plenty of surface treatments for your choice, for example oxidation, electrophoresis and static powder coating, etc.

2. Strict control for surface finish, very little scratch.

3. Accurate mold as well as accurate size.

4. Standard alloy composition

5. Both ends of the profiles are very plain and with no burr.

FAQ

1. What is your main product?

We can supply the aluminium complete system, including aluminum billets, aluminum profile for windows and doors, aluminum for curtain wall, alumimun framwork, and kinds of aluminum windows and doors.

2. What’s your price?

The price is based on buyer's specific requirement, so please provide below information to help us quote exact price to you.

3. What is your payment term?

30% - 50% down payment, the balance payment against, and L/C is available.

- Q: What are the different shapes available for aluminum profiles?

- There are various shapes available for aluminum profiles, each designed to suit different applications and requirements. Some commonly used shapes include: 1. T-Slot profiles: These profiles have a T-shaped cross-section, with slots on one or more sides. They are widely used in construction, robotics, and industrial applications, as they allow for easy assembly and integration of other components. 2. Square profiles: These profiles have a square-shaped cross-section and are often used for structural applications. They provide excellent strength and rigidity, making them suitable for building frames, machine bases, and support structures. 3. Rectangular profiles: Similar to square profiles, rectangular profiles have a rectangular-shaped cross-section. They offer versatility and can be used in a wide range of applications, including enclosures, partitions, and conveyor systems. 4. Round profiles: These profiles have a circular cross-section and are commonly used in applications that require a smooth and aesthetically pleasing finish. They are often used for architectural purposes, such as handrails, furniture, and decorative elements. 5. L-Shaped profiles: L-shaped profiles have a 90-degree angle and are often used for corner joints, edges, and brackets. They provide structural support and stability and are commonly used in construction and manufacturing industries. 6. U-Shaped profiles: U-shaped profiles have a U-shaped cross-section, resembling an open channel. They are frequently used in applications that require a protective housing or a channel to guide cables, wires, or other components. 7. Custom profiles: Apart from the standard shapes mentioned above, aluminum profiles can also be custom-designed and manufactured to meet specific project requirements. This allows for greater flexibility and ensures the aluminum profiles perfectly fit the intended application. Overall, the availability of different shapes for aluminum profiles enables engineers, designers, and manufacturers to select the most appropriate shape for their specific needs, ensuring optimal performance, functionality, and aesthetics.

- Q: Are aluminum profiles resistant to impact or vibration?

- Yes, aluminum profiles are generally resistant to both impact and vibration. Aluminum is known for its high strength-to-weight ratio and excellent durability. It can withstand external forces and impacts without easily deforming or breaking. Additionally, aluminum's natural properties make it inherently resistant to vibration. It has a high damping capacity, meaning it can absorb and dissipate vibrations, reducing their effects. This makes aluminum profiles an ideal choice for applications where impact or vibration resistance is required, such as in the construction, automotive, aerospace, and marine industries.

- Q: Can aluminum profiles be used in window and door manufacturing?

- Window and door manufacturing can utilize aluminum profiles. Aluminum is a favored material for window and door frames because of its numerous advantages. It is light in weight, long-lasting, resistant to corrosion, and offers a superb strength-to-weight ratio. Aluminum profiles can be easily molded and tailored to fit various window and door designs, enabling flexibility in the manufacturing process. Moreover, aluminum frames require minimal maintenance throughout their lifespan. They also possess exceptional thermal and sound insulation properties, making them energy-efficient and capable of reducing noise transmission. In conclusion, the versatility, durability, and performance benefits of aluminum profiles make them extensively employed in window and door manufacturing.

- Q: Are there any specific requirements for transporting and storing aluminum profiles?

- Yes, there are specific requirements for transporting and storing aluminum profiles. Aluminum profiles should be handled with care to prevent any damage or deformation. During transportation, they should be properly secured to avoid shifting or falling. It is recommended to use protective packaging and cushioning materials to prevent scratches or dents. When storing aluminum profiles, they should be kept in a clean and dry area to prevent corrosion. It is advisable to stack them horizontally or on racks to avoid bending or warping. Additionally, they should be stored away from direct sunlight and extreme temperatures.

- Q: 3030 aluminum profiles, can be used in outdoor snow exposure environment?

- European standard 3030 series has a variety of specifications, such as Jing Teng aluminum European standard 3030R, referring to the European standard 3030 fan, 3030G refers to the 3030 GB profiles.

- Q: This question asks for an explanation of the manufacturing process of aluminum profiles.

- <p>Aluminum profiles are made through a series of processes starting with the selection of high-quality aluminum ingots. These ingots are melted in a furnace and then extruded through a die to create the desired profile shape. The extrusion process involves forcing the molten aluminum through a shaped opening in the die, which gives the aluminum its final form. After extrusion, the profiles are cooled, straightened, and cut to length. They may then undergo secondary processes such as anodizing, powder coating, or painting for enhanced durability and appearance. Finally, the profiles are inspected for quality and packed for distribution.</p>

- Q: This question asks for a comparison between aluminum profiles and other materials regarding their visual appeal and aesthetic qualities.

- <p>Aluminum profiles are often favored for their sleek, modern appearance and high aesthetic value. They offer a clean, silvery finish that can be anodized or painted to match various design schemes. Compared to materials like wood, they provide a contemporary look, while their uniformity and precision in manufacturing can surpass the natural variations found in wood. When compared to plastics, aluminum profiles offer a more premium feel and are often perceived as more durable and high-quality. Additionally, aluminum's recyclability and low maintenance requirements contribute to its eco-friendly and aesthetic appeal in sustainable design.</p>

- Q: This question asks for an overview of the various types of aluminum profiles that are frequently utilized in the field of commercial construction.

- <p>Commonly used aluminum profiles in commercial construction include: 1. Extruded aluminum profiles, which are versatile and can be customized for various applications. 2. Structural aluminum framing, used for building structures and curtain walls. 3. Aluminum window and door frames, known for their durability and energy efficiency. 4. Aluminum handrails and railings, important for safety in commercial buildings. 5. Aluminum trusses, used for roof structures and large spans. 6. Aluminum angles and channels, used for support and framing. 7. Aluminum tubes, used in various structural and decorative applications. These profiles are chosen for their strength, lightweight, corrosion resistance, and ease of maintenance.</p>

- Q: What unique considerations or criteria must be met when installing aluminum profiles in areas with heavy foot traffic?

- <p>When installing aluminum profiles in high-traffic areas, special requirements include selecting profiles with high load-bearing capacity, using durable materials resistant to wear and tear, and ensuring the profiles have slip-resistant surfaces. It's also crucial to consider the ease of maintenance and cleaning, as these areas will require more frequent upkeep. Additionally, profiles should be designed to withstand frequent contact and potential impacts, and they must comply with safety regulations to prevent accidents.</p>

- Q: I have a disinfection cabinet to cut off a piece of aluminum to install the control board, how to cut? What tool to cut?

- The use of wire saw can be sawed, if you cannot use a wire saw, it can only be used to drill holes along the need the position of the drill hole, finally use a tool to trim it to the edge.

Send your message to us

Aluminium Extrusion Profiles For Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords