Extruded Aluminum Track

Extruded Aluminum Track Related Searches

Plastic Profiles Bamber Bridge Door Architrave Profiles Victorian Architrave ProfilesHot Searches

Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Used Metal Folding Chairs For Sale Large Metal Containers For Sale Metal Shop Cabinets For Sale Metal Shipping Crates For Sale Solar Inverter Price In China Best Solar Inverter In China Solar Inverter Price In Dubai Solar Inverter Price In Uae Solar Inverter Price In Kenya Solar Inverter Price In Kerala Solar Inverter Price In Ghana Solar Inverter Price In Nepal Solar Inverter Price In Ksa Fiber Sheet Price In India Fiber Roofing Sheets Price In Pakistan pvc pipe manufacturers in usa Types Of Scaffolding In Construction PdfExtruded Aluminum Track Supplier & Manufacturer from China

Okorder.com is a professional Extruded Aluminum Track supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Extruded Aluminum Track firm in China.Hot Products

FAQ

- Yes, aluminum profiles can be used for signage. Aluminum is a versatile and durable material that is commonly used for various signage applications. It offers several advantages such as being lightweight, corrosion-resistant, and easy to work with. Aluminum profiles can be easily formed into different shapes and sizes, making them suitable for a wide range of signage requirements. Additionally, aluminum profiles can be powder coated or painted to achieve the desired color and finish, enhancing the overall appearance of the signage. Moreover, aluminum is a sustainable material as it is highly recyclable, making it an environmentally friendly choice for signage projects. Overall, aluminum profiles are a popular choice for signage due to their durability, versatility, and aesthetic appeal.

- Yes, aluminum profiles can be used for balustrades. Aluminum is a lightweight and durable material that is commonly used in construction for its strength and resistance to corrosion. It is also easy to shape and work with, making it ideal for creating various designs and styles for balustrades. Additionally, aluminum profiles can be powder coated or anodized to provide a decorative finish and enhance its durability. Overall, aluminum profiles offer a practical and aesthetically pleasing solution for balustrades in both residential and commercial settings.

- Yes, aluminum profiles can be used in the construction of retail displays. Aluminum is a versatile and lightweight material that is commonly used in various industries, including construction and retail. It offers several advantages for retail displays, such as durability, corrosion resistance, and ease of customization. Aluminum profiles can be easily shaped and fabricated to create different types of retail displays, such as shelving units, display stands, signage frames, and product showcases. These profiles can be extruded into different shapes and sizes, allowing for flexibility in design and functionality. Additionally, aluminum profiles can be finished with various surface treatments, such as anodizing or powder coating, to enhance their appearance and provide a protective layer against scratches and wear. This allows retail displays to maintain their aesthetic appeal and withstand the demands of a retail environment. Furthermore, aluminum is a sustainable material as it is highly recyclable, making it an environmentally friendly choice for retail displays. It can be easily recycled without losing its properties, reducing the environmental impact of construction and retail industries. In summary, aluminum profiles are a suitable and practical choice for the construction of retail displays. They offer durability, versatility, and customization options while being lightweight and environmentally friendly.

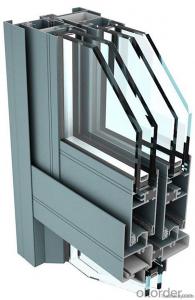

- The 50 series and the 60 series of aluminum profiles, which one is good?

- Of course, 60 of the good.60 and 50 refers to profiles, from the indoor to outdoor overall thickness of 60MM and 50MM. respectively60 of the cross section is larger than 50 1cm, much stronger. The glass gap that can be installed is also larger

- What is the difference between the two, or how to distinguish it from the outdoor curtain wall?

- Aluminum material refers to the blank material, which is used directly without artificial aging

- What are the differences between the 6005 and 6003 aluminum profiles?Yangmingxg3

- 6003 of the magnesium content is higher than 6005, and the strengthening of magnesium to aluminum is remarkable. With the addition of 1% mg, the tensile strength increases by about 34MPa.

- Yes, aluminum profiles can be used in medical equipment manufacturing. Aluminum is a lightweight and durable material that offers various advantages for medical applications. It is corrosion-resistant, which is crucial in medical settings where equipment is often exposed to chemicals and sterilization processes. Aluminum profiles also provide excellent thermal conductivity, allowing for efficient heat dissipation in medical devices. Furthermore, aluminum profiles can be easily customized to meet specific design requirements, allowing for the creation of complex and precise medical equipment. They can be machined, welded, and formed into various shapes and sizes, making them suitable for a wide range of medical applications, such as surgical instruments, imaging equipment, patient beds, and wheelchairs. In addition to its mechanical properties, aluminum is environmentally friendly and recyclable, aligning with the growing sustainability requirements in the medical industry. It is non-toxic and does not release harmful substances, ensuring the safety of patients and healthcare professionals. Overall, aluminum profiles offer numerous benefits for medical equipment manufacturing, including durability, corrosion resistance, thermal conductivity, customization options, and sustainability.

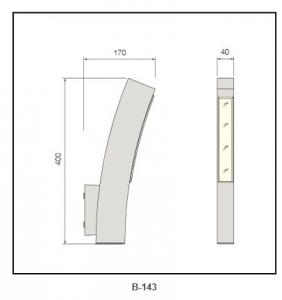

- The dimensions and sizes of aluminum profiles can vary greatly depending on their intended use and design. They can range from small and narrow profiles, such as 10mm x 10mm square tubes, to larger and wider profiles, such as 100mm x 100mm square tubes. Additionally, aluminum profiles can come in various shapes, including square, rectangular, round, and custom shapes, to accommodate different applications and structural requirements. It is important to consult specific product catalogs or manufacturers for precise dimensions and sizes of aluminum profiles.